To manage your shop floor (or any other part of your enterprise), you need to have reliable data about the situation on the shop floor. Even with reliable data, the remaining uncertainty makes good management a challenge. Many managers, to save precious time, rely on data and information provided to them by their people. This is a grave mistake! Always verify at least part of the data with you own eyes! You would be surprised how different – and usually worse – it is in reality.

A Few Anecdotes…

Throughout my career I have seen lots of examples of managers being ignorant of the real situation on the shop floor. The following conversation is a real example with a manufacturing plant manager, albeit without source to protect the (not so) innocent.

Me: How much time do you spend on the shop floor?

Plant Manager: Oh, about one hour or so.

Me: Per day?

Plant manager: No, per week!

Another plant manager visited the shop floor only if there was a bigwig to show around. The plant manager was scared of his employees asking him questions that he could not answer.

Overall, managers usually spend way too little time on the shop floor, and way too much time in meetings and at the computer. As a result, they are usually blissfully unaware of what is really going on on the shop floor.

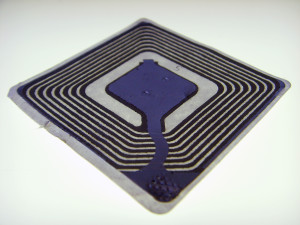

There are tons of anecdotes for this too. For example, in another plant, RFID was implemented to improve the material control (RFID: Radio Frequency Identification tags, small chips that respond to a wireless inquiry). After completion of the project, a successful presentation was given to management and everybody was happy. None of them knew that the ERP suite behind it was so slow that the workers just ignored the RFID completely and entered the data by hand like they always did.

There are tons of anecdotes for this too. For example, in another plant, RFID was implemented to improve the material control (RFID: Radio Frequency Identification tags, small chips that respond to a wireless inquiry). After completion of the project, a successful presentation was given to management and everybody was happy. None of them knew that the ERP suite behind it was so slow that the workers just ignored the RFID completely and entered the data by hand like they always did.

As a result, an expensive RFID system was set up but not used. Surely somebody knew. But nobody told management. Instead, they provided a whitewashed version of the truth (i.e., they lied about the real situation). For more examples, check my post Lies, Damned Lies, and KPI – Part 1: Examples of Fudging and Lies, Damned Lies, and KPI – Part 2: Effects of Fudging.

Everybody Lies

There are many different studies on how often people lie, usually with quite drastic results. Depending on which study you believe, most people can’t go for ten minutes without telling a lie (Robert Feldman: The Liar in Your Life: The Way to Truthful Relationships). At the same time, very few people in the study realized that they were telling lies.

And, to a certain degree, this is necessary. If you would be brutally honest all the time, you probably would have very few friends. This also extends to industry, where too much honesty can be bad for the career. Surely you have had experience with a manager who habitually shoots the messenger. Other managers seem to believe that good people make no mistakes. With most managers, it is often better to tread carefully.

Even an open-minded manager (like you [hopefully] are) tends to look more favorably on people who (appear to) return the positive views. This is just in our human nature. We like people who like us back. In sum, everybody lies – some more, some less.

No Matter What, You Will Get Fooled. The Question Is: How Much?

Since everybody lies at least a little bit, you will definitely be lied to regarding the situation on the shop floor. Or, to phrase it more kindly, you will get a selective version of the truth (lie is such a harsh word). Some may be white lies, some may be more serious. But there is no way around the fact that some of the information you are getting is less than truthful, while other information is not mentioned at all. Due to the aforementioned reasons, you will usually get an overly optimistic view of the positive side, and little or no information on the negative side. This is, of course, unless the person wants to block or stop the project, in which case the negative side is emphasized.

You will be fooled at least some times! The question is: How much? Your goal should be to reduce the misinformation and to increase the accuracy of the data. Yet, you have to accept that you will not be able to eliminate it completely.

Real Place, Real Situation, Real Parts!

And that’s where the reality comes in. The closer you get to reality, the more reliable the data will be. You must check at least some of the information you receive at the source.

Japanese lean experts often refers to this as the three reals. They all start with the same kanji 現, which stands for reality, existing, actual, current, or present. These three reals conventionally stand for these three terms (although there are many more Japanese words that start with 現):

Gemba (現場, sometimes also written Genba): actual spot; scene; scene of the crime; site; location; sometimes also shop floor

Genbutsu (現物, sometimes also written Gembutsu): actual articles; actual goods; the real thing

Genjitsu (現実): reality; actuality; hard fact

In English, Gemba usually refers to the shop floor, although depending on your value stream, it may be anywhere where it is really happening. As for Genbutsu (現地現物), you may also have heard of Genchi Genbutsu. This would be yet another “Gen-” word:

Genchi (現地): actual place, actual location, local, on-site

So, Genchi Genbutsu (現地現物) means nothing more than to look at the real products in their actual location (i.e., in situ (just in case you prefer Latin 😉 ).

How to Check…

Verify Some of the Information

Ideally, a manager should check everything on the shop floor. Practically, he/she doesn’t have the time for it. Ohno’s chalk circle is good but too time consuming as a regular exercise for managers. Hence, there is no way but to make sample checks. As for that, more is better. Most managers seriously underestimate the time they should spend on the shop floor.

Have a Plan or a Routine

When visiting the shop floor, it is easy to be physically present but mentally absent. Personally, I have two strategies to address this problem. Strategy 1: Have a routine. Walk the same path every time, and try to see if it looks different from before. In fact, do not only rely on looking, but also see if it smells different, sounds different, or generally feels different. Some people can feel if a stamping press is working correctly based on the vibration they have.

Strategy 2: Focus on a narrow problem. Do not try to look at everything, because you will only see nothing. Focus on a particular aspect that is of interest to you to verify some information you received from your people. For some more tips, see also Make Your Plant Tour a Success!, or for a sarcastic view on how to be fooled, check How to Misguide Your Visitor – or What Not to Pay Attention to During a Plant Visit!.

Foster a Culture of Openness

If your people are getting shot for reporting bad news, it is only natural that they will stop reporting on the negative side and emphasize the positive side. You have to accept that even with the best intentions, sometimes things go bad. Focus on a solution, not on a scapegoat. If you shoot the messenger, messengers will be much more hesitant to come.

React If You Are Fooled

If you find out that someone misleads you, you must act! Tolerating being fooled is probably the worst thing you can do. If the fooling works, it is a success for the employee; if it doesn’t, there are no negative consequences. It is your job to introduce negative consequences if you are misled, in order to improve the quality of the information you receive.

Your actions determine if you reduce the number of liars in the company, or if you reduce the number of honest ones. In any case, always keep in mind that some of the information you receive will be misleading, no matter what. Now, go out, look at your shop floor, and organize your industry!

I agree. This has been my experience. Take a walk throughout your day and analysis if procedure are being followed. If not, ask why it is not. Your employees will notice that you are passionate in making improvements and they will know you are following up with them. Get their input for more improvements and they will maintain the procedures since they are involved in the decision making. Review the process to see if changes can be made to improve the process. You will also notice if the environment can be cleaner and more efficient. Becareful on how you talk and act towards your people. Show them respect and kindness so they know you are trying to help them instead of calling them out. Create a Kaizen team to help you and the company. The team will help in improvement processes and keep others in line. Show them how to read body language and be leaders with respect to others. Teamwork will get you more then freelancing.

Nice article , Christoph ! Thks for sharing ! Roberto

Ismelda & Roberto: Many thanks for the compliments 🙂

A truly valuable blog and great article! Only remark the convenience of a presence in shop floor in active manner and with the aim of questioning assumed facts. Like a dummy or too easy presence becomes counterproductive. I remember an extreme case of an ingenious engineer who had a rule shortened (the rule starts with a half of centimeter instead of 0). This gimmick device was conveniently used when it came to prove that there were no dimensional defects of some parts with mounting problems in assembly line (with the annoyance of workers to mount it). I hope this tale doesn’t serve as new possibilities for cheating…

Many thanks, Francisco. Great story of human trickery! Yet shortening the ruler just to show problems most likely backfired. If someone would accuse me of making something 1/2 cm to short, I would measure myself as soon as possible. Thanks for sharing!

Toyota way principle 11. sounds simple but difficult to practice, for long term in particular

True. Principle 11: Respect your extended network of partners and suppliers by challenging them and helping them improve.

Thanks for such great article. It felt as if I was reading my own experience in an article. I give so much emphasis for Gemba (Shop floor) visit minimum once a day. However even Engineers would consider it as an insult to be in shop floor, expecting Technicians & Line leader to provide all the data. Some escalates to whistleblowers / ethics departments against these hand-on or Shop-floor focus MFG approach. Upon change of Management team, I was informed that Manufacturing Engineers, Managers and Top Managers of a Leading Medical Device Manufacturing plant in Malaysia are given the privilege to be absent from Shop-floor. Some even not been to factory for > 1 years – working from home. In my view & experience, these new work cultures let lower level employees to continue to live with problems and shoulder the Quality pressure and The golden goose (The Company) continuous to bleed.

Many thanks, Kumanan, for sharing your story. It is not always, but way too often like this all over the world. And, as you said, home office during Corona made things worse (albeit I believe it was necessary to keep the pandemic in check). We have to find a way to get relevant people in the factory more often again.