Modern manufacturing works with a lot of performance measures, often called key performance indicators (KPIs). Unfortunately, they are rarely accurate, and often even intentionally misleading. In my previous post I described some examples of commonly manipulated KPIs. In this post I would like to explain the ugly consequences of incorrect or manipulated KPIs. In a final post I will also show some ways that you can reduce this negative effect. But first, how do bad KPIs (and hence most KPIs) hurt your company?

Emphasis on Treating Symptoms over Actual Cure

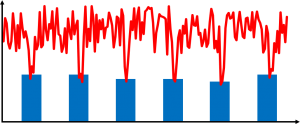

Performance indicators are merely a representation of actual performance. Yet, with a big focus on these measurements, the measurement becomes more important than the actual performance. One frequent KPI where I have encountered this is inventory. Common wisdom states that a lean company has little inventory. It is less well known that this reduced inventory is the result of hard work in improving the system.

The easy way to reduce inventory is to simply order less stuff. However, this does not make the company lean. On the contrary. If the manufacturing system is not yet ready to work with less inventory, simply reducing inventory will decrease efficiency and performance. All too often in my consulting life, the recommendation was to actually increase inventory to get out of the constant firefighting and to have time to fundamentally change the performance before being able to sensibly reduce inventory. However, frequently nothing was allowed to damage the inventory KPI, no matter how much sense it would have made.

Wasted Effort on Measuring and Analyzing KPIs

Usually, a lot of effort goes into measuring KPI. Some KPIs are measured by hand, where people count, take notes, and write down the data. Usually, this data is also input into a computer. Other measurements are taken almost automatically, for example through an ERP system. However, even then they need to be managed, analyzed, and reported.

One example I have seen measured a total of 45 logistics KPIs for one plant, half of which were measured daily. This took over two hours every day. My guess is that nobody looks at 45 KPIs, and this is just information overload. Hence, two hours wasted every day for something nobody looks at?

Additionally, a lot of these KPIs are not reliable, hence the entire effort above is a waste. On top of that, I have seen way too many performance measurements that were taken with great effort and then never used. They were established at one point due to a manager having a question related to this performance. Since then the manager has long forgotten his question, the question is no longer important, and the data is not looked at. Yet, the measurement still continues. As a manager myself, I was able to win quite some brownie points with my guys by stopping performance measurements that had long since lost their meaning. Of course, this included the risk that a year later somebody would ask for this KPI and I would not have it, but for me that was worth the risk.

Even More Waste in Manipulating KPIs

KPIs do not manipulate themselves. Lots of effort goes into actually manipulating them. In the easy case, all the loopholes of the regulation and calculation methods are utilized to get the maximum KPI out of the same system. See again my Top Three Methods on How to Fudge Your OEE for an example.

However, all to often this effort goes way beyond simple number fudging, and turns into actually harmful behavior toward the company. Maybe you remember the example of the end-of-month inventory measurements from my last post? Many plants regularly run out of material at the end of the month since material was only allowed to arrive after the 1st of the next month.

Even worse, some plants regularly loaded up their high-value goods on trucks, drove them to the highway rest stop, and parked it there until the end of the month. Hence, the goods did not show up in the inventory at the end of the month, but they were still there. Except there was the substantial additional effort of loading, unloading, transporting, and renting trailers.

Another option is to use an external warehouse. You paid for the goods, they are already there, but they are not on your inventory books. Of course, this is also not free and the logistics provider takes his cut.

Or, lets take another example of costs. One popular approach to look good is to simply sell all your buildings and property (sometimes even with the machines), and rent it back immediately. In the short term you get a large cash inflow. In the long term … well … you better move to another position before the long-term comes around. However, since your cash flow KPI is good, it should not be a problem.

I’m sure you have seen many more examples of counterproductive activities in your career. Hence, all too often lots of company money is burned to make the numbers look good, rather than improving the system!

Bad Decisions Based on Bad KPI

Being a manager is a tough job. There is the constant need to make decisions without having all the information available. This uncertainty makes most people uncomfortable, even though they rarely admit it (although I am more scared of managers with a consequences-be-damned style of worry-free decision making). The higher up you go, the larger the uncertainty.

In this situation, KPIs are especially dangerous. There is a perceived accuracy of numbers on which a decision can be based. However, these decisions cannot be better than the numbers. Yet, as we have seen, these numbers are often not worth the paper they are written on. Hence, flawed KPIs give flawed decisions. As the uncertainty increases with hierarchy, unfortunately so does the quality of the KPI decrease. The CEO of Daimler Schrempp once famously (and correctly) called his headquarter a “bullshit castle.”

To give you a smaller example, purchasing products for Europe and America are often sourced in Asia based on cost calculations that made them a fraction of a percent cheaper that way. Unfortunately, these cost calculations did not include a lot of quite relevant factors like delays, uncertainty, differences in quality standards, emergency air freight cost, and so on. Effectively it was much more expensive than local sourcing, even though the numbers still showed them to be cheaper. Well, the numbers were wrong, and so was the decision!

Worst of All: It Hurts the Honest People

I reserved the worst effect for last: KPI manipulation usually rewards the manipulators. There are, basically speaking, two ways how you can make the performance indicators go up. First, you put in the work and improve the underlying system. Secondly, you fiddle with the numbers. Of course, it would be much better for the company to improve the underlying system. However, it is much easier to merely fudge the numbers.

All too often the superiors do not notice this number fudging (which is surprising, since all too often it is what got them in their position). Yet compensation is usually based on these performance indicators. Hence the dishonest ones get a better bonus. Even worse, the dishonest ones are much more likely to make a career, whereas the honest “underperformer” languishes in lower-level jobs or even may get fired (like the dishwasher tab manager in my last post).

Hence, KPI manipulation is a natural selection of the manipulators for higher positions. It is also self accelerating, as the more liars a company has, the more they will get.

Conclusion

Well, my last post stated that performance measures are often way too crooked. This post states that all the measuring may actually be more harmful than good. The question is, do we still need KPIs?

Well … yes. I admit I was toying with the idea of throwing all KPIs out of the window – but that would be too radical. A large corporation cannot be managed without at least some performance measures. Hence, we indeed do need measures! However, more care has to be taken when establishing, measuring, and especially verifying these KPIs. I will present some suggestions on how to improve this problem in my next post. Unfortunately, these suggestions are neither easy nor a cure for all your KPI-related woes. However, they will help! In the meantime, go out and organize your industry!

Series Overview

- Lies, Damned Lies, and KPI – Part 1: Examples of Fudging

- Lies, Damned Lies, and KPI – Part 2: Effects of Fudging

- Lies, Damned Lies, and KPI – Part 3: Countermeasures

See also

Roser, Christoph. “Richtig Messen – KPIs Zum Nutzen Des Unternehmens Einsetzen.” Yokoten 5, no. 1 (2016): 26–29.

Yep, you can’t underestimate the corrosive effect that sort of fudging has. Once it starts to happen regularly, it’s extremely difficult to break out of that pattern. Not when half of the managers and supervisors have their entire careers hinging on the numbers being good.