There are different ways to manage workers in an manual U-line. One of these methods is known as the “Rabbit Chase,” also known as the “Caravan Approach” or “Operators-in-Motion.” The workers always move in a circle and handle all processes in sequence.

There are different ways to manage workers in an manual U-line. One of these methods is known as the “Rabbit Chase,” also known as the “Caravan Approach” or “Operators-in-Motion.” The workers always move in a circle and handle all processes in sequence.

Introduction

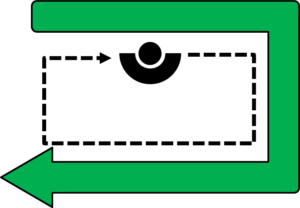

The Rabbit Chase is a possible approach to organize manual work in a flow line. The worker moves along the line with his part. When the worker reaches the end of the line, he picks up a new part and starts again. Naturally, this works best for U-shaped lines, or in general lines where the end is close to the beginning of the line.

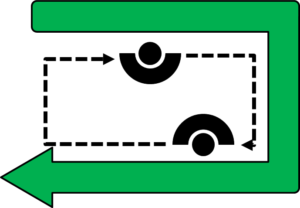

If there is only a single person working in the line, however, this would not (yet) be a rabbit chase. For a rabbit chase you need more than one person. The image here shows an example with two workers.

You probably can easily see where the name “Rabbit Chase” comes from. The faster worker will be “chasing” the slower worker.

This is also one of the possible drawbacks of this method. The system speed is limited to the speed of the slower worker, and the faster worker may have to wait for the slower worker.

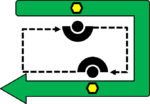

Working Direction

The direction in which the workers walk is very clear: they should go forward with the part! This way the worker processes one and only one part throughout the entire line. This has two advantages.

First of all, you need less inventory. If the workers walk backward, they would need a new part waiting at every preceding process. The line would have many more parts. The lead time would increase, without a corresponding increase in line performance.

Second, if the worker is responsible for one part from beginning to end, then the quality is probably better. When walking backward, any quality issue in a part will soon be the problem of the other worker. While the size of this effect varies, there may be a tendency toward a “no longer my problem” attitude. When walking with the parts, however, the part is the worker’s problem from beginning to end.

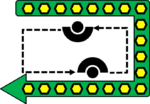

How Many Workers?

How many workers can you put in the line? Well, theoretically as many as there are stations. However, adding too many workers can have quite a drawback.

How many workers can you put in the line? Well, theoretically as many as there are stations. However, adding too many workers can have quite a drawback.

The problem is that the workers have to wait for the slowest worker. The more workers you have in the line, the more workers have to wait. You end up with a manufacturing version of a traffic jam.

As for how many workers you want to add, it depends on the length of the line (or more precisely on the duration it takes for a worker to make a circle) and how much waiting time you are willing to accept. The exact relation is hard to determine.

Theoretical Model – Fixed Speed

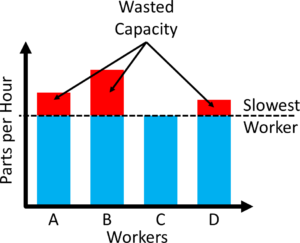

If you would (unrealistically) assume that all workers always have a constant speed, then the wasted capacity would be any capacity faster than the slowest worker.

If you would (unrealistically) assume that all workers always have a constant speed, then the wasted capacity would be any capacity faster than the slowest worker.

The image shows this for an example, with four workers with different working speeds (indicated in parts per hour). Since the slowest worker C sets the speed, the other three will be trailing behind. Any excess speed of the other three workers is lost, since they cannot overtake the slowest worker. But, as I said, this is an unrealistic worst case assumption.

Realistic Model – Variable Speed

In reality, the speed of the worker varies over time. Sometimes he can work the process faster, sometimes slower. This is a natural variation of the cycle time that happens in most manufacturing lines. In this case a worker may sometimes be the slowest worker, but later may speed up again.

In reality, the speed of the worker varies over time. Sometimes he can work the process faster, sometimes slower. This is a natural variation of the cycle time that happens in most manufacturing lines. In this case a worker may sometimes be the slowest worker, but later may speed up again.

Hence, the distance between the workers varies. The distance between the workers can act here as a buffer, allowing workers to catch up and fall back again as their speed changes over time.

While this will not completely cancel out the problems of wasted capacity and waiting times, it will probably be much less than the case assuming a constant speed. Unfortunately, the exact value is difficult to calculate. Overall: Do not put too many workers in a rabbit chase line, or the waiting time may become too much. Some sources actually recommend no more than two workers, although I can imagine cases where more than two workers may be possible.

While this will not completely cancel out the problems of wasted capacity and waiting times, it will probably be much less than the case assuming a constant speed. Unfortunately, the exact value is difficult to calculate. Overall: Do not put too many workers in a rabbit chase line, or the waiting time may become too much. Some sources actually recommend no more than two workers, although I can imagine cases where more than two workers may be possible.

Summary

Let me give you a brief run-down of the pros and cons of a rabbit chase.

Advantages

- Easy to set up and manage

- Low inventory

- Fast lead time

- Clear responsibility leading to better quality

Disadvantages

- Slowest worker sets the speed of the system (although this is found in many systems, excluding the bucket brigade).

- Possible mental pressure on slower worker due to the worker hindering everybody else.

- May cause a traffic jam behind the slowest worker.

- Significant walking distances. Each part requires a worker walking the entire line (but similar to many other systems where workers walk).

- Every worker needs to know all processes from the beginning, and training of new workers may be more difficult.

- Not very scaleable. Adding more workers will increase output, but not linear.

Overall, the Rabbit Chase style of managing a flow line may or may not be the best option for you. There are definitely situations where this may make sense, but in other cases there may be better ways to manage your line.

Anyway. As usual, I hope that this post was interesting to you. Now go out, chase some rabbits (or even better, improvement potentials), and organize your industry!

I remenber I put an U rabbit line for hanging garments order assembly, based in manual sortation from an aerial conveyor, in Inditex, 23 years ago. Lenght of the line was in the range of 100 m and was occupied by several operators with enough espace between, so as to not to create delays.

We used the same principle for flatpacked garments. In this case, units were transported on trolleys at ground level. Fast operators could overtake slow ones.

Regards.

Hi Juan, excellent. A 100m rabbit chase is surely longer than anything I have seen 🙂 . As for the flatpacked: If they can overtake each other it probably is no longer a rabbit chase, but also probably a cool solution. I assume this was in commissioning of products for shipment.

Your assumption for flatpacked garments is right.

Hi Christoph and thank you once again for a interesting and well done post! This time i would like to ask you a little “of the topic” question. What kind of software do you use to create/draw these simple and easy to understand pictures that you use in almost every post? I ask this because i would like to use something similar to easy visualize what i want to describe to someone and these pictures you have in your posts do exactly that.

Thank you in advance!

Best regards, Alexander

Hi Alexander, i simply use PowerPoint. For additional tweaking I use the freeware GIMP (and sometimes IrfanView, but GIMP has more options). Finally TinyPNG to compress images before uploading. After 3 years at McKinsey, you cant help but being good at PowerPoint 🙂

Hi and thank you very much for this information! I have had not heard of GIMP before but PowerPoint is used heavily here at my work and then i do not count presentations 🙂

Gimp is like Adobe Photoshop, but completely free. A very powerful tool, of which I use less than 10% of what it can do.

somebody knows haw many feets or meters are allowed to walk the day.

Hi Daniel, there is no fixed limit. of course walking is waste, and less is better. U-shaped lines can help here. if the distance is too short and (almost) all stations are staffed all the time, you may end up with one worker in the middle without work.

How would you suggest measuring cycle time for a U-Cell with two workers doing the rabbit chase method?

Hi Reggie, it is a bit tricky. Cycle time would be the fastest time that you can repeat. Hence it should be the sum of the cycle times of all stations plus the time needed for one operator to walk along the line back and forth once (or the loop once, depending on the layout) divided by the number of people in the line.

Hi, Christoph, thanks for your interesting post. I have a question. If we already have the target CT, which methods can help us to set up the NO. of workers in the line? The lead time of one worker divide the target CT?

Hi Wang,

the number of workers is the total workload divided by the target CT. However, it also depends on how you can divide the work between workers. See my series on line balancing for more details.