Have you ever been to a value stream mapping workshop? If so, you may remember the insistence of the coach to start any mapping activities at the customer side (the end) and then work your way backward (to the beginning). Yet, if you would ask why, you would get only some vague answers about this way being better, more lean, or just the way Toyota does it. In this post I want to go into more detail about whether it may be beneficial for value stream mapping to start at the customer side, and why.

Lean – The New Religion

Many people are so convinced of this that they would not do anything on the shop floor unless it is started at the customer side. Yet, if you ask about the reasons for this you will get a very vague answer. In sum, the reasons for starting at the customer side are usually not known but considered part of the lean religion: If Toyota does it, then it must be good, and we will do it too, even if we don’t understand why!

In my view, this approach goes totally against the Toyota Production System, where you should use common sense first and foremost and do only the things that you thoroughly understand. But fear not, AllAboutLean.com is here to help. I will give you the key reasons for starting plant tours and value stream mapping at the customer side…

Top Five Reasons for Walking from the Finished Goods to the Raw Materials

First of all, starting a value stream mapping or a plant tour by walking from the customer or finished products side toward the raw materials does indeed have some benefits. However, these benefits are overall not as significant as they sound, and in my view are often over-emphasized to impress the uninitiated. They do bring some advantages, but it is also completely possible to walk through the plant in the other direction.

1 – Mental Weight to the Customer

Starting at the customer side gives mentally more weight to the customer. If in your business the customer is important (and it should be), you can put your money where your mouth is. It is one small part of setting the attitude and changing the mindset in your organization.

2 – New Thinking Through Different View

Most people habitually walk through the plant from the raw materials toward the finished goods. For the people in the plant, this is the way they see and understand the plant. By walking through the plant in the opposite direction, you are forcing them out of their normal behavior patterns. You require them to behave differently. Maybe, just maybe, it may also make them think differently. Maybe they notice something new simply because of the (minor) additional mental effort to do things the other way. It may be worth a try.

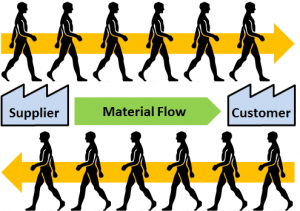

3 – See the Information Flow in Pull Systems

In value stream mapping, we try to describe both the material and the information flow. In a typical plant, the material flow is rather easy to see. Just follow the parts. The information flow, on the other hand, is more difficult to see. It may be electronically, or through paper, and much less obvious than the material flow.

In a push system, information is handed out centrally. Hence, it makes no difference which direction you walk if there is a push system. In a pull system, on the other hand, information flows in the opposite direction of the material flow. Walking in that direction enables you to follow that information. For example, if you are at a supermarket, try to find out where the Kanban goes. This will give you a much better understanding of the information flow, but only if you walk with the information from the customer to the supplier.

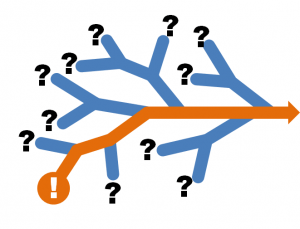

4 – Understand Branches in Material Flow

Assume you don’t know the plant and walk along the value stream from raw materials to finished goods. Usually, someone from the plant accompanies you and gives you the tour of the plant. This guide also usually picks the starting point on the value stream. There is a chance that at one point, another component merges with the product, and that other component may be more interesting. Now you may have wasted time by walking along the less-interesting value stream.

If you start on the other side, however, you could, at every branch, pick the direction in which you want to follow the value stream towards it source. That way you could have a more meaningful view of the value stream, so it is beneficial to start at the finished goods.

In reality, however, most products have one key component, and your guide usually starts with those. Additionally, most people I have seen on plant tours would never dare to change the official route, or ask critical questions. This is one of the reasons why it is so easy to misguide visitors. Overall, starting at the customer side may be better, but it is also not a big deal.

5 – Sound Smart

The last reason, honestly, is kind of lame. The last reason for starting at the customer side is simply that it makes you sound smart. You seem to know something that others don’t know. (I told you it is a lame reason!) It is especially popular with consultants 😕 . Nevertheless It enhances your credibility and may give you more leverage to change things (unless, of course, the others read AllAboutLean.com, too). Such things are not to be underestimated. On the other hand, if this is the only reason for starting at the customer side, then that would be pretty sad.

Examples When Maybe NOT to Start at the Customer Side but the Supplier Side

Overall, starting at the customer side and walking toward the supplier side is not a huge benefit. But then, it is not a huge inconvenience either. Hence I usually start at the customer side and walk toward the supplier side for value stream mapping and plant tours.

However, there are also a few instances where this direction is suboptimal.

Understanding the Physical Production Process

If you don’t care about material and information flow but simply want to know how the product is made, then walking from the supplier to the customer is more insightful. For us, building a product piece by piece comes easier than the reverse process. Hence, if your interest is the product and not the production, then start on the supplier side.

Implementing Pull

Implementing a pull system increases availability and reduces inventory. Most larger factories have multiple loops to create the finished product. If you convert a system from push to pull, you probably have to create multiple loops. For this you have to start somewhere. Many plants start at the customer side since it is flashier and gives more brownie points with upper management.

However, for a Kanban loop or any pull system to work, it is critical that there’s a good availability of raw materials. Kanban systems quickly fall apart when there is frequent lack of materials going into the pull system. So you have to ensure that material availability is good. One possibility is more inventory – which will not go over well with management regardless of how necessary it is. The other possibility is starting the pull loops on the supplier side. If the first raw material supply is steady, it allows you to create a solid next pull loop. Hence, for implementing Kanban and pull systems, it may be better to start at the supplier side – although the customer side is fancier.

Overall, in my view it is a small advantage to start from the customer side. However, this is not a huge benefit, and if you prefer to start from the supplier side, you will probably have very similar results. I hope this post showed you some reasons for starting at the customer side and some examples when not to. If you think I missed one, please let me know.

Now go out and improve your industry!

Hi, Enjoyed reading your article. I am thinking for a learner like me it would be great to view a finished example of VSM from the customer side, so I get a mental picture of it end to end. Is there an example I can view in another article or blog? Thanks in advance.

Hi Gerry,

the VSM I have are unfortunately proprietary by my clients, hence I cannot share them. Sorry.

You need to manage more than just your value streams. Are you fishing in the right stream?

The most important factor for achieving organisational success is to have a clear view of the changing nature of competitive advantage. A company’s ultimate success will be determined by the effect their actions have in the market place not just within their own organisation. —

As we progress further into the 21st century more organisations are delivering quality products and services and achieving the various required market accreditations. They are also introducing lean thinking, six sigma, supply-chain management and information technology to gain competitive advantage. Unfortunately when everyone achieves this, they will all be the same and no one will have any significant advantage. —

To gain a new level of competitive advantage we must create new dimensions of customer satisfaction. This new dimension comes from identifying; creating and managing the total range of ‘Experience’ customers can enjoy when doing business with your organisation. These experiences must include, but go beyond those created by products and services. They must also satisfy all the customers’ physical and emotional needs and engage all their senses when enjoying them. —

A brief look at the history of competitive advantage shows these changes. First Age 1950 – 1980 Product. Throughout the 1950 to 1980 period, companies saw products as the main source of competitive advantage. The goal was continuous product innovation and the improvement in product quality, cost and delivery.

Second Age 1980 – 2000 Product and Service. As products became harder to differentiate, the competitive battle continued on the product front with the added dimension of customer service. Benefits the customers could enjoy in addition to those given by the product. Third Age 2000 – Customer Experience Management. Companies are now realising that even when products (P) and services (S) are excellent, this still does not guarantee competitive advantage in the 21st century marketplace. The battle must continue in the product and service areas, but to gain a new level of competitive advantage we must create a new dimension of customer satisfaction. This new dimension comes from identifying, managing and satisfying the total range of physical and emotional experiences (E) customers can enjoy in all the direct and indirect contact with your organization. This is the ‘Customer Experience Stream’. —

Organisational success depends upon delivering the best P.S.E’s available in your industry. To sustain it requires them to be continuously improving these values faster than any existing or future competitor”. The ultimate ‘Success Factor’ is not only to create and manage your internal ‘Value Streams’ (VS), but to provide the most enjoyable/appropriate external ‘Experience Streams’ (ES) in your market place. These experiences must not only satisfy all the customers’ business needs, but also the personal physical and emotional needs of the people who work for it. —

There is one final stream needed to ensure your success. This is the most important ‘stream’ in any organization; it is the stream/flow of your people’s ability (AS, ability stream). From the combination of these three flows (VS, ES and AS), we can create and sustain a torrent of competitive advantage. —

Management teams must realise that one of their main goals is to release and focus the ability of all their people into these streams. To maintain these flows, they must ensure their own people ‘Experience’ a working environment that is; secure, challenging, fulfilling and a fun/enjoyable place to be.

Happy fishing!

PS. I think blockages in the ‘Ability Stream’ are one of the main reasons change programmes fail.

Two significant benefits of starting at the customer end are that (1) it leads to deeper understanding, and (2) it helps to reveal waste.

If you start at the supplier end, you frame the process in terms of its inputs, and you emphasise the process over the aims of the process. On the other hand, starting at the customer side frames the step in terms of its outputs, and helps emphasise the why along with the how.

The biggest benefit of this is that it helps reveal waste. If you understand what a process is supposed to achieve, it is easier to see aspects of the process that don’t contribute to that puspose.

Dear Cristoph, VSM looks good for serial manufacturing. In my case, we are manufacturing machines for pharma sector. In this case, data box is not easy to fill in, because we don’t have a serial pieces.

Can you recomend me how to fill in data box?

Thanks

Gabriel

Hi Gabriel, there is no fixed rule on what to put in the box. The question is what kind of data do you need?

For the processing industry it could be liter/ton/kilo etc per hour; changeover times; number of workers working at the process (although in processing the number will be most likely zero); number of parallel machines (if any); uptimes, etc.

For non-processing production in a high mix environment the same holds true: What data do you need – although in this case it is also combined with what data do you have? Number of workers? Cycle times for different products, or averages? etc.

Hope this helps,

Chris

Thanks chris We are not working on serial machines, but on projects. Each order is different because customers need their specific conditions. I mean, we’re working on projects. We don’t have stock.