Twenty-five years ago today, William Edwards Deming (October 14, 1900 – December 20, 1993) passed away. He greatly influenced the management of quality in Japan, where he is still revered as one of the great gurus in manufacturing. Through his influence on Toyota, his ideas are now common in the lean world. Time to look back at his life.

Twenty-five years ago today, William Edwards Deming (October 14, 1900 – December 20, 1993) passed away. He greatly influenced the management of quality in Japan, where he is still revered as one of the great gurus in manufacturing. Through his influence on Toyota, his ideas are now common in the lean world. Time to look back at his life.

Family Life

Deming was the eldest of three children of William Albert Deming and Pluma Irene Edwards, born in October 14, 1900, in Sioux City, Iowa. His name is a combination of his father’s first name and his mother’s last name, and he was called Edwards to avoid confusion with his fathers name, William. His dad was an insurance broker and his mom was a piano teacher. He had a brother Robert (1902) and a sister Elizabeth (1909).

While he grew up rather thrifty on a farm in Polk City, Iowa, and later in Powell, Wyoming, his parents were both well educated and valued the education of their children.

He married his first wife, Agnes Bell, in 1922, and they adopted a daughter, Dorothy, in 1924. However, Agnes died in 1930, and he married again in 1932 to Lola Elizabeth Shupe, a mathematician. They had two more girls, Diana (1934) and Linda (1943).

Academic Career

Deming obtained a bachelor’s in engineering at the University of Wyoming in Laramie in 1921. He also taught briefly at that school.

In 1922 he became an assistant professor of physics at the Colorado School of Mines, while simultaneously obtaining a master’s degree in mathematics and physics at the University of Colorado in 1924.

Afterward, he worked briefly as an hourly worker at Western Electric’s Hawthorne Works in Chicago. Maybe you have heard about the famous Hawthorne Experiments. These studies by Elton Mayo and Fritz Roethlisberger analyzed the influence of different factors such as illumination on work performance. Surprisingly, the performance increased regardless if they made it brighter or darker, no matter what they did, as long as they paid attention to the workers (although modern researchers are much more critical about the quality of the study). While Deming was not involved in the study at all, the calculation of the payments he received from his manual work set his opinion firmly against financial incentives of any kind.

In 1926 he went to Yale, and received his Ph.D. in 1928 for “A Possible Explanation of the Packing Effect of Helium.”

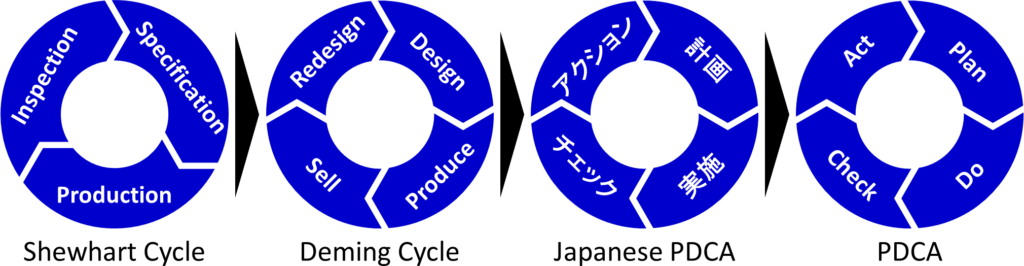

Afterward he worked for the United States Department of Agriculture, first as a mathematician and later as a lecturer. During this time his career took a turn from physics to quality control. It was also at this department where he met Walter Shewhart (1891–1967), which developed into a flourishing professional exchange over the next decades. Shewhart is considered the father of statistical process control, and he developed a cycle for quality control in his book edited by Deming in 1930. Later Deming updated this to the Deming Cycle, which slightly modified made its way into Japan, and now is known as PDCA, although Deming disliked the PDCA version (see here for more).

In 1939 he switched jobs and joined the Bureau of Census. There he developed statistical survey methods that significantly influenced the 1940 census.

The War Years

In 1942, Deming was asked to help with statistical training to help the war effort, and he soon trained engineers, inspectors, and industrial people in an intensive eight-week course. The impact of this course on the war is disputed; you can find a lot of praise but also some critical voices.

In 1942, Deming was asked to help with statistical training to help the war effort, and he soon trained engineers, inspectors, and industrial people in an intensive eight-week course. The impact of this course on the war is disputed; you can find a lot of praise but also some critical voices.

After the war was over, his work was no longer needed, and he worked as a consultant for some time. A lot of the productivity and quality achievements during the war were now on the back burner or even forgotten.

Deming in Japan

In 1946, Deming was asked to come to Japan to support agriculture production, and in 1947 to help with the 1951 census. He and Joseph Juran were part of a group of experts of the U.S. Headquarters in Japan tasked with improving productivity and (the back then still arguably shitty) quality of Japanese products, although Deming only got on board because the first preference declined to go to Japan. Unlike many other experts, Deming and the Japanese got along well. He became a frequent visitor of Japan.

The Union of Japanese Scientists and Engineers (JUSE) tried to understand the U.S. concept of statistical quality control, but got stuck in some theory. Hence, in 1950 they asked Deming to come back and help them. Deming developed and held numerous lectures and seminars on statistical quality control, which were well received and very well attended. His courses were subsequently also taught by others. Other courses on sampling methods had much less popularity.

Deming did not accept royalty payments for his course. As a sign of gratitude, JUSE established the Deming Prize for Quality in 1950, with the first awards given in 1951. This is by far the most prestigious quality award in Japan. Nissan won the price in 1960, and as a response Toyota introduced Total Quality Control (TQC) in 1961, also winning the Deming Prize in 1965. In 1950, Deming also met with twenty-one of Japan’s most important industrial managers, which was a turning point for his influence. Overall, Deming is still revered in Japan.

Re-Import of the Japanese Methods to the United States

All these achievements in Japan were pretty much unnoticed in the West, and Deming, too, was pretty much unknown in his home country except to insiders.

All these achievements in Japan were pretty much unnoticed in the West, and Deming, too, was pretty much unknown in his home country except to insiders.

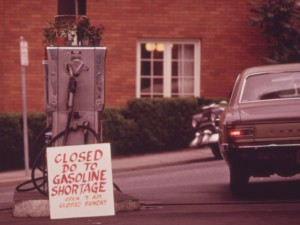

This changed in the aftermath of the 1973 oil crisis that seriously hurt the Western automotive industry but apparently not the Japanese. Besides the study of “the machine that changed the world,” another landmark was the 1980 NBC documentary If Japan Can, Why Can’t We?, which talked about and with Deming for fifteen minutes.

As part of the wave of lean manufacturing, quality control and Deming’s ideas made their way back to the United States. A lot of the methods that the United States developed during the war and pretty much abandoned afterward were re-introduced through Japan. During this time, Deming also rose to industrial superstar status in the United States and the Western world.

He died on December 20, 1993, in Washington, DC, aged 93.

A Demigod of Quality?

As Deming rose in prominence in the United States, the media outdid itself with praising his achievements, making him appear much larger than he truly was, and calling him “the man who discovered quality” and “founder of the third wave of the Industrial Revolution.”

If you believe in Deming as a flawless demigod of quality, you better stop reading. He achieved a lot, but this is nowadays often exaggerated. He even made it on a mural of a church as a (sort of) saint. Selected sources are below.

From 1964 onward, JUSE started to believe that while Deming was excellent in statistics, he lacked practical industry experience. Also – and this is common with successful people – he valued his own achievements while overlooking all the people who contributed. While he developed the courses for statistical quality control in Japan, the method originated from Walter Shewhart, and Shewhart should get the praise for that.

Another common flaw of people who are praised excessively is to eventually believe the praise (just ask your CEO how wonderful he is …). And Deming as an academic with many publications was just much more accessible than Homer Sarasohn, who also taught statistical process control in Japan, but as an industrialist and with a much higher focus on practicability.

Deming once dissed the Malcolm Baldrige Quality Award, since he believed it should have been named after him. He also believed that he alone made the difference in Japan’s success. Personally, I believe Joseph Juran (1904–2008) had a much bigger influence in Japan in particular and on quality management in general. Deming also gave his name to the American Society for Quality (ASQ) for an (U.S.) Deming Prize. This greatly offended JUSE and their (Japan) Deming Prize, and they were not consulted on this second prize with the same name. Deming opposed Total Quality Control (TQM), stating that Statistical Quality Control was all that is needed.

On the other hand, there are also numerous reports and anecdotes of his kindness and helpfulness. He was also known for his humor and consideration of others. Overall, he was the right person at the right time and helped to spread the valuable tool of Statistical Quality Control in Japan and later in the rest of the world.

His Legacy

Deming is known for spreading statistical quality control in Japan and the world, as well as helping to put quality on the agenda of industry. He is also the author of 14 key principles for Total Quality Management (not to be confused with the 14 Management Principles of The Toyota Way by Jeffrey Liker). These principles are, in my view, sound and good common sense, although Deming took a lot of inspiration from other sources for that list. (Source for the two lists below: Wikipedia article on Deming.)

- Create constancy of purpose toward improvement of product and service, with the aim to become competitive, to stay in business, and to provide jobs.

- Adopt the new philosophy. We are in a new economic age. Western management must awaken to the challenge, must learn their responsibilities, and take on leadership for change.

- Cease dependence on inspection to achieve quality. Eliminate the need for massive inspection by building quality into the product in the first place.

- End the practice of awarding business on the basis of a price tag. Instead, minimize total cost. Move toward a single supplier for any one item, on a long-term relationship of loyalty and trust.

- Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease costs.

- Institute training on the job.

- Institute leadership. The aim of supervision should be to help people and machines and gadgets do a better job. Supervision of management is in need of overhaul, as well as supervision of production workers.

- Drive out fear, so that everyone may work effectively for the company.

- Break down barriers between departments. People in research, design, sales, and production must work as a team, to foresee problems of production and usage that may be encountered with the product or service.

- Eliminate slogans, exhortations, and targets for the workforce asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the workforce.

- Eliminate work standards (quotas) on the factory floor. Substitute with leadership. [Please note that I am a fan of standards, but not a fan of pay-by-piece. I believe Deming here means pay-by-piece rates]

- Eliminate management by objective. Eliminate management by numbers and numerical goals. Instead substitute with leadership.

- Remove barriers that rob the hourly worker of his right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality.

- Remove barriers that rob people in management and in engineering of their right to pride of workmanship. This means, inter alia, abolishment of the annual or merit rating and of management by objectives.

- Institute a vigorous program of education and self-improvement.

- Put everybody in the company to work to accomplish the transformation. The transformation is everybody’s job.

He also created a list of the “Seven Deadly Diseases,” which are also sensible.

- Lack of constancy of purpose

- Emphasis on short-term profits

- Evaluation by performance, merit rating, or annual review of performance

- Mobility of management

- Running a company on visible figures alone

- Excessive medical costs

- Excessive costs of warranty, fueled by lawyers who work for contingency fees

So, here you have it. Overall, I like Deming and his contribution to Japan, although I am a bit skeptical of his glorification. Now, go out, improve your quality, and organize your industry!

Selected Sources

- Juran, Joseph M.: Architect of Quality. McGraw-Hill, 2003. Especially pages 300–306 have a critical view on Deming.

- Hopper, Ken, and Hopper, Will: The Puritan Gift: Triumph, Collapse and Revival of an American Dream, I. B. Tauris 2007

- Murals of Deming can be found in the St. Gregory of Nyssa Episcopal Church in San Francisco, along with Anne Frank, Mahatma Gandhi, and many others (and yes, I know that neither Anne Frank nor Gandhi were Christians … don’t ask me to explain religious logic …)

Just one comment about the Hawthorne studies: they have been debunked. They are now an example of shoddy work in social sciences and we should stop repeating as established the conclusions they fail to support.

Hi Michel, thanks for the input. I added a link to the critical section on Wikipedia to the article. I think this is not a clear cut case of right or wrong, hence I would not really say “debunked”. In any case, the Myth is definitely bigger here than the facts. I believe it is not as crooked as the pig iron moving data from Taylor at Bethlehem Steel, he fudged the numbers to get the results.

I joined Nissan in 1985. During induction they went through their history, proudly mentioning being awarded the Deming Prize in 1960. In the UK we have The Queen’s Award for Industry etc. which some companies have been awarded several times. I wondered if Nissan had likewise been awarded the Deming Prize on subsequent occasions?

It was explained that the Deming Prize represented a particular level of achievement, and that as a Deming Prize Winner Nissan remained – 25 years later – at that level.

To digress a little: a few years later, at JUSE’s TPM division (if you can call it that?!) I had discussions regarding the various TPM prizes. Could any company / plant seek evaluation and accreditation if they believed they were at the appropriate level? No! You have to buy the consultancy programme first!

Hi Steve, Nissan won the prize multiple times: 1959, 1992,1995,1996, (the last three for specific plants (Source)

Hello Dr. Roser,

I opine that your article has a few shortfalls when describing Deming’s history as well as the JUSE comments. I’d also like to give some insights from other important sources in post-war Japanese history.

https://imgur.com/a/4Ky9Bf3

In the link above is the obituary of Kenichi Koyanagi who was among the founding directors of the JUSE. This obituary was written by W. Edwards Deming and published in The American Statistician in 1965. This clearly shows that Deming himself is saying that Koyanagi was the tip of the spear when it came to JUSE’s impact on Japanese industry from the integration of quality and business management viewpoint. He also was the one who was active in asking for lecturers to come in to give seminars (Tsutsui, p. 193 in link above). Ichiro Ishikawa, the other founding member was also important, although from what I remember from reading the JUSE’s papers (in English) was that Ishikawa from his corporate relationships was responsible for getting the top corporate management to attend the lectures (this is from my own memory, I can’t find the source online any longer!).

William Tsutsui wrote an article on Deming’s glorification exaggeration in much greater detail “W. Edwards Deming and the Origins of Quality Control in Japan” in 1996 available via JSTOR. Tsutsui is a Japanese-American who can read fluently in Japanese. He subsequently published a book on the topic in broader detail. Tsutsui made a big mistake in his article, which was one of exclusion. He never bothered to have read the journal articles written by the man whose glorification he was criticizing. If he did, he would have found the obituary article as I did on the first search page results.

Halfway, we are going to change direction of focus. One of the biggest exclusions in analyzing the total economic revival and subsequent dominating Japanese economy by historians has been the understanding of the finance sector’s role in propping up the industrial giants and their associating keiretsu’s. Economist Richard Werner whom spent 12 years in Japan as chief economist of Jardine Fleming and BoJ researcher which in his book, “Princes of the Yen” (2003) describes how the Japanese economy worked in the viewpoint of financial structuring. The operation of the Ministry of Finance was to be the central command of credit creation and its issuance to industry. The private banks would then finance their industrial companions’ credit for their business operations (Werner p.130 “The BoJ-Run Loan Cartel”). The only catch for private banks would be that they needed to show to the MoF that the loan money was given to appropriate customers, the industrial sector. This was the somewhat the same mechanism used throughout the war period when the Imperial Japan gave credit to those whom where part of the warfare industrial sector. In other words, in the post-war economy up until the 1990’s was a modeled after the mobilized war economy, in which the production of goods was geared towards consumer goods, not war materiel. And they blew away the competition beyond their wildest dreams.

I left the best for last. Dr. Osamu Shimomura (not the chemist) was head of MoF while he began to make these connections during his time when architecting the Japanese economy. Shimomura’s ideas were instrumental in the formulation of Prime Minister Ikeda’s ambitious National Income Doubling Plan. It worked. (see Link above for Werner’s Ch 7. Pg. 73).

Here is a NHK documentary on the subject including Shimomura himself

https://youtu.be/mKN7ya6Dq7E

Here is Richard Werner’s book in a shortened documentary form. https://youtu.be/p5Ac7ap_MAY

Hi Cristian, something as big as lean/TQM/turning Japan around/etc is never the product of one person. There are countless people that contributed, although the fame often goes to a single individual that (rightfully or not) catches the spotlight. I mentioned a few (Walter Shewhart, Homer Sarasohn, Joseph Juran, Ichiro Ishikawa), but a complete list would exceed the scope of my article. I did mention that he got the limelight. I have not heard of Kenichi Koyanagi , but based on your links I believe that he contributed, too. Thanks for the input and the lengthy comment.

Thanks for this post… here is what I posted yesterday about Dr. Deming:

https://www.leanblog.org/2018/12/25-years-since-dr-deming-passed-away/

Hi Christoph,

Definitely some interesting content in your article on Deming… Glad to see that you drew some of the content from Ken (and his brother William) Hooper’s book. In that regard, I sense that there are quite a few nuances related to Deming’s activities in Japan post WWII (i.e., what his original mission was, how he was the second choice to work with the Japanese… Schewhart being the first recommended by Sarasohn, the highly complimentary nature between Sarasohn’s/Protzman’s CCS training curriculum and what Deming later promoted, the fact that “participative management” (as introduced by Sarasohn) is a key underlying principle for the conduct of kaizen activities, etc.) have been either overlooked or intentionally omitted.

From my POV, these sorts of omissions tend to reflect/promote a bias favoring the impact of Deming’s activities over and above those of other notable players who also made significant – if not more so – contributions to the Japanese Miracle.

Your reply to another comment – by another reader – above acknowledges the fact that such a transformation, as occurred in the Japanese Miracle, is never the work of a single individual is an accurate depiction of reality. HOWEVER, IF, you truly read the Hoopers’ book, cover-to-cover, then I believe it would be difficult to dismiss – or underplay – the roles that other folks played in facilitating Japan’s post WWII recovery, and its subsequent rise to prominence in the world economy; especially in the manufacturing arena. And as a secondary source of confirmation of my position, I offer a more recent (2008) article that provides a very well done summary of the events and players involved in the post WWII (1945-1950) occupation period. I will suggest that it was these events/endeavors that actually the laid the foundation for the successful subsequent reception of Deming’s teachings and evolution of Japan a global economic powerhouse.

Here’s a link to that article (in PDF format) from the International Statistical Review (2008) entitled: Homer Sarasohn and American Involvement in the Evolution of Quality Management in Japan, 1945–1950, by N. I. Fisher (School of Mathematics & Statistics F07, University of Sydney, NSW 2006, Australia)

https://www.researchgate.net/publication/46537675_Homer_Sarasohn_and_American_Involvement_in_the_Evolution_of_Quality_Management_in_Japan_1945-1950

Note: Don’t know when Deming developed his 14-Points, but they align very closely with the teachings of Sarasohn/Protzman as found in the CCS training manual they developed and presented during their time in Japan.

Hi Jay,

thanks for the long and detailed comment and the link to the PDF. Sometimes we just want to put people on a podesta and glorify them beyond the facts. I try to avoid this and try to give a nuanced view. Hence in my blog post I also included a few points critical of Deming’s “holy aura”. Your comment included much more information, and I am always happy to get a different view from the mainstream (and sometimes I hopefully also offer a different view myself). I have to admit that I did not (yet) read Hoppers book in full, but I should put that on my ToDo list.

Again many thanks for your comment!

For me the most outstanding thing about Dr Deming was his integrity and humanity. Without these qualities thought leaders cannot be trusted.

It is my view that that a knowledge of principles is much more valuable than a haystack of facts. I wonder what Dr Deming would think of these universal management principles defined in 2014 as part of MSS 1000? https://www.integratedmanagement.info/universal-management-principles