If you’re doing lean, you will encounter people telling you to do “5 Why” everywhere. And the method sounds simple, just ask “Why?” five times to find the root cause of a problem. However, there is a surprising amount of depth to this, as well as some pitfalls. Let me elaborate:

If you’re doing lean, you will encounter people telling you to do “5 Why” everywhere. And the method sounds simple, just ask “Why?” five times to find the root cause of a problem. However, there is a surprising amount of depth to this, as well as some pitfalls. Let me elaborate:

A Simple Method?

The technique of “5 Why” can be found everywhere on the web. Googling “5 Why” gives slightly over 3 million results. The basics of 5 Why is rather simple. You just ask the question “Why?” five times to find the root cause of a problem. This is often illustrated with a simple example like:

- The car will not start.

- Why? – The battery is dead.

- Why? – The alternator is not functioning.

- Why? – The alternator belt has broken.

- Why? – The alternator belt was worn out.

- Why? – The car was not maintained (the root cause). (Source: Wikipedia “5 Whys”)

This technique is popular in literature, and also with management, at least in theory. While some sources describe it in more detail, many others oversimplify the process, in which case it may look like this: The manager simply asks the subordinate “Why?” five times in a row, after which the subordinate has found the root cause and can get to work fixing it. There is no mental involvement needed for the manager. If it were only that simple …

This technique is popular in literature, and also with management, at least in theory. While some sources describe it in more detail, many others oversimplify the process, in which case it may look like this: The manager simply asks the subordinate “Why?” five times in a row, after which the subordinate has found the root cause and can get to work fixing it. There is no mental involvement needed for the manager. If it were only that simple …

The Proper Way to Ask Why

What Kind of Problems Can Be Solved with 5 Why?

5 Why is a technique that follows a path rather linear to a single root cause. Hence, it is usually best with problems that probably have only a single root cause, or at least very few root causes. The more possible causes a problem has, the more difficult it will be to use this method.

For example, if your problem is “Our company is not making money!” 5 Why may not be the right method. While it will eventually lead to one answer, it is highly doubtful that this is the most important one, and in all likelihood it is not the only cause. In this case, other methods like fishbone diagrams or brainstorming may yield better results.

As always, before setting out to solve a problem, make sure it is a relevant problem! In your work, you will encounter a myriad of problems, only a few of which you can solve. Invest your time and the time of your people in a problem that will make a difference for your company (see, for example, my post How to Manage Your Lean Projects – Prioritize).

Once you have the problem defined, think about how to approach the problem. 5 Why may or may not fit all problems. Do not start with “I want to do 5 Why” and then think about which problem you could solve. Always start with the problem!

And, as always in lean, whenever possible go to the site of the problem and have a look directly at the current situation: Go to Gemba! (many thanks to Thomas Meyer for the suggestion)

Who Do You Want to Ask?

5 Why can be done with a larger group, one-on-one, or even by yourself. The people involved need to know about the problem and have the ability to analyze its causes. It is okay to ask the mechanic in charge why the machine breaks, but it would probably not help to ask the accountant.

Evaluate and Verify the Answers

The success of 5 Why depends a lot on the quality of the answers. If the answers are guesses, then the outcome will be random. Let’s take the example from above, “The car will not start,” where the first answer was “The battery is dead.” If this is correct, the path of the questions will continue successfully. However, if the answer was wrong, and the car was out of gas, then you will end up with a false root cause. Changing the maintenance standards for the battery will not help you with an empty gas tank.

The success of 5 Why depends a lot on the quality of the answers. If the answers are guesses, then the outcome will be random. Let’s take the example from above, “The car will not start,” where the first answer was “The battery is dead.” If this is correct, the path of the questions will continue successfully. However, if the answer was wrong, and the car was out of gas, then you will end up with a false root cause. Changing the maintenance standards for the battery will not help you with an empty gas tank.

Another popular answer (at least in Germany) is to blame someone else. “The car will not start. Why? It is the fault of the other person/department/company/etc.” This, of course, is not helpful. Focus on the process, not the people.

Also, causes are often mixed up with symptoms. Make sure that with each why, you get the next cause of the problem.

Hence, with every answer you and/or your team needs to verify if it is correct, useful, and the only or at least the most likely answer. In some cases this may be obvious; in others it may require some testing and data collection.

How Many Whys?

The method is known as 5 Why, and most examples show exactly 5 whys. However, this is only a rule of thumb, and also a catchy name (“6 Why” feels odd). In fact, I rarely exceed 3 Why. Maybe my mind jumps over steps. Take again the example from above, “The car will not start,” where the first why could already be: “Why? The alternator belt has broken,” followed by “Why? The car was not maintained.”

The method is known as 5 Why, and most examples show exactly 5 whys. However, this is only a rule of thumb, and also a catchy name (“6 Why” feels odd). In fact, I rarely exceed 3 Why. Maybe my mind jumps over steps. Take again the example from above, “The car will not start,” where the first why could already be: “Why? The alternator belt has broken,” followed by “Why? The car was not maintained.”

Using the example above, it is also easy to imagine more than 5 whys. It is easy to continue the example above from “Why? The car was not maintained,” to “Why? Maintenance is overworked,” to “Why? There are too few people,” to “Why? The budget was cut,” and so on. <sarcasm> Only on AllAboutLean.com do you get 8 Whys for the price of 5 😛 </sarcasm>

Hence, the number of whys can be flexible! More important than the number of whys is knowing when to stop. You should continue to ask why (and verify the answers) until you arrive at an answer where you can fix the problem for good. Often, 5 Why ends when an answer points to a process! A part can be fixed, but this fix is only good until the part breaks again. Changing a process, however, is much more likely to prevent the problem from arising again.

Also, if your last “Why?” ends up pointing to the fault of an employee, it may be worthwhile to ask “Why?” at least once more. A mistake by an employee is often due to lack of training, lack of time, lack of tools, overwork, or other organizational causes. Thanks to David Norby for the suggestion.

Multiple Root Causes

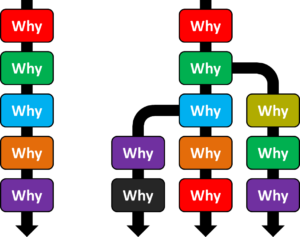

Another common problem with 5 Why is multiple root causes. A given problem may have more than one cause that contributes to the problem. It is possible to track these branches and ask “why” questions following up each individual branch. However, the more branches there are, the more cumbersome it will be. Hence, as described above, 5 Why is usually best suited for problems with few or even one possible root cause.

The Therefore Test

After going through the 5 Why, there is also a test going back in reverse. This is called the “therefore” test or “So what” test. This is a test to check the validity of the answers. While not foolproof, it may help you to make sure your logical chain is correct. Using the example above it would look like this:

- The car was not maintained.

- Therefore therefore the alternator belt wore out.

- Therefore the alternator belt broke.

- Therefore the alternator was not functioning.

- Therefore the battery was dead.

- Therefore the car did not start.

(Many thanks to Phil Ledbetter for the suggestion!)

Caveats

5 Why is good for problems with few or even only one root cause. However, often you don’t know beforehand about the root causes. If you do know the root cause, the whole process of finding the root cause in the first place may not be necessary. This brings me to the formality of the method.

Occasionally this method is mentioned as a full-blown 5 Why workshop, where a team is assembled to be asked “Why?” five times. I find that risky. You don’t know beforehand how the process will split. You don’t know beforehand how often to ask why. And telling your people beforehand that you will ask them “Why?” five times is more likely to annoy them than excite them.

Hence, I believe this method is not suited as the program for a formal workshop, but more as an internal method for the moderator. Do not announce that you are doing “5 Why,” but instead just do it as you see it fit! It is, after all, only an aid to help you dig deeper. It also should not be your only tool in your toolbox in finding the root cause, but should be combined with other approaches.

At least in German you can vary the wording, where “Why” can be translated to “Wieso,” “Weshalb,” “Warum,” and “Weswegen,” giving you already four variants for the five whys. In English, however, you are stuck with “why.” The only other variant I know is “Wherefore,” but this is terribly archaic, and you should avoid using it unless you habitually wear a frock and a monocle. Nevertheless, try to get some variation in your questions or risk sounding like a nosy kid.

At least in German you can vary the wording, where “Why” can be translated to “Wieso,” “Weshalb,” “Warum,” and “Weswegen,” giving you already four variants for the five whys. In English, however, you are stuck with “why.” The only other variant I know is “Wherefore,” but this is terribly archaic, and you should avoid using it unless you habitually wear a frock and a monocle. Nevertheless, try to get some variation in your questions or risk sounding like a nosy kid.

5 Why to Find the Root Problem

5 Why is one of many methods to find the root cause for a problem. However, I also use this frequently in the other direction to find the root problem to a given solution. When I talk with managers on the shop floor, I often ask them what they consider to be their biggest problem they want to address. And all too often, I get a response like: “We want kanban.”

Ding-ding-ding – WRONG! Kanban is a solution, not a problem. I am a firm believer in starting any lean activities from a problem. Just copying the solution of someone else will fail. And kanban is a solution that may or may not fit the problem at hand. Hence, I often find myself going 5 Why in the other direction, for example like this.

- We want kanban.

- Why? Well, because Toyota does it successfully.

- No, really, why do YOU need kanban? Because we often have stoppages due to lack of material.

- Why? Because the material arrived too late.

- Why? Because our material flow is chaos.

- Why? Because our order and reproduction process is disorganized.

- Okay, so your problem is actually a disorganized order and reproduction process. Let’s move forward from that.

You get my point? Sometimes you first have to find out what is really the problem before solving it.

Something Different: 5W1H

Let me also quickly introduce a method that sounds similar but is for a different purpose. 5 Why is sometimes abbreviated as 5W, but this risks being mixed up with 5W and its variants 5W1H and 6W. The 5W (or 6W) and the 1H stand for

- Who (was involved)

- What (happened)

- Where (did it take place)

- When (did it take place)

- Why (did that happen)

- How (did it happen)(for 5W1H)

- Which (will you make/do)(for 6W)

The sequence is, by the way, not standardized. Nor is the exact list of questions. Some users prefer “To whom” over “why”, or add a second H with “How much“. There are lots of possibilities here, too, to fit this method to your needs (Thanks to Koen van Dam for the suggestions). This is not so much a method for root-cause analysis but rather a structured set of questions to get the overview of a situation. This set of questions covers the breadth of a topic rather than the depth. As such it is also useful, but for a different purpose.

Summary

5 Why on its own is a quite limited tool. It is also not suitable as the main structure for a full-blown formal workshop. However, as an underlying approach to dig deeper for the actual root cause, it is quite useful. As with most lean tools, it is not so much the tool as the skill of the user that determines the success. Now go out, keep asking why, and organize your industry!

very good..thanks

Excellent, thank you.

Now ,ı know when to use 5 why.Thanks for sharing.

A good article that helps to clear up some of the Myths about 5 Why.

The key to starting is to ensure the problem is clearly defined.

I have seen so many sessions fail as the problem was not clearly defined at the start.

There is only ever 1 root cause, but there can be many contributing factors.

The test is when you get to a root cause is to ask “if I fix this root cause does it eliminate the problem from ever occurring again”?

Hi Mar, depending on how you define the problem there could be more than one cause. These could differ in significance, or both be important. It is nice to have only one root cause, but I believe that is not always possible.

I find it helpful to complete the fishbone diagram with the team and down select possible problems. You know the car wont start, but as stated there are several possible reasons, so a little investigation goes a long way to figuring out the first why.

Good points all around. 5 why’s, Ishikawa,and dependent on complexity, even a thorough process mapping exercise to identify the rocks will ultimately find the solution to the true root cause.

The root cause as provided by you in the example of car breaking down is incomplete. 5 Why is much more of a philosophy than a mere tool. Firstly it is not actually about how many why’s one asks, its all about when the person asking Whys to find answers starts to acknowledge that the reason lies within self (either directly controlled or influenced). Its all about internal locus of control.

For example we ask further than the fifth why to Car was not maintained well. WHY ? It indicates to either no reminder for car maintenance, no tracking of the same, Further ask a WHY and you are hitting to a solution which is influenced or controlled by the owner of the car. Its precisely the right WHY which has even led to companies maintaining a database of time schedule of servicing for every car. High end cars have configure the reminder for service on dashboard itself. 5 Why is much more powerful than what its taught or discussed.

Across countries during training programs, depending on the culture (e.g. Indian managers won’t discuss “reason lies with me openly). i ask participants to ask WHYs till its indicating to a solution which is either influenced or controlled by you. It could be 3-4-5 -10 or beyond Whys also !!

Good insight !

Great insight into improving the usefulness of a classic tool.

As the article said, 5 Why is not the main tool but is come as an important supplement tool in problem solving process. 5 Why is used together with FishBone. Once all the probable cause has been identified and the most relevant cause/causes has been picked up by the team, the next thing is to use 5 WHY on the probable cause/s to nail down to root cause.

Good Insight.

Great Insight as usual Christoph. I have long been wondering about the origin of the 5 Why approach. The answer came to me through Patrick Graupp at the last TWI summit in June. And you will be amazed at how it links your recent. Article topics.

Patrick interviewed Mr Isao Kato who spent 35 years in Toyota and was deeply involved in the development of their training materials and system: Isao and Taiichi Ohno we’re discussing one day the TWI Job Methods module and how to teach it, in particular how to get people to ask the 5W1H (why what where when who how) questions you mention above. Ohno said « we can not ask all these questions » considering it was too complex. Kato answered « then we will ask Why 5 times ». The rest is history: the 5 Why techniques is the result of a reaction from Ohno considering TWI JM questions not simple enough…while Job Methods ironically targets methods improvement, ie simplification and waste removal

Interesting. I did not know that. Very nice and thanks for sharing!

Thank you for sharing, I’m fairly New to lean and didn’t really grasp the depth or usefulness of 5 why,s Especially combined with the fishbone tool.

Great insight into improving the usefulness of a classic tool.

we also help for Ngo to find goverment project