A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

Christoph Roser

Interview on the David Pakman Show on the Future of Manufacturing

Recently I had the exciting opportunity to be interviewed on the David Pakman Show on American TV, where I talked about the future of manufacturing, especially in America. Our subjects of discussion ranged from “bringing jobs back,” to the presidential election, to the carbon tax and many more current issues. Here’s the full video and also the transcript:

Recently I had the exciting opportunity to be interviewed on the David Pakman Show on American TV, where I talked about the future of manufacturing, especially in America. Our subjects of discussion ranged from “bringing jobs back,” to the presidential election, to the carbon tax and many more current issues. Here’s the full video and also the transcript:

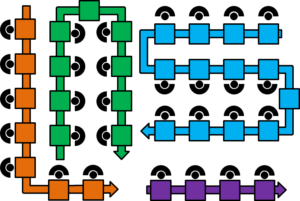

Line Layout Strategies – Part 2: I-, U-, S-, and L-Lines

The layout of a line can make quite a difference in the performance of your line. The U-line is most famous, although in my view while good it may not be the right thing for all situations. There is also the I-line, the S-line, and the U-line. In my last post I described some general thoughts on line design and took a look at the big picture. In this post I want to look at and compare actual line layouts, in particularly the I, U, S, and L layout. Let me give you an overview of the different options.

The layout of a line can make quite a difference in the performance of your line. The U-line is most famous, although in my view while good it may not be the right thing for all situations. There is also the I-line, the S-line, and the U-line. In my last post I described some general thoughts on line design and took a look at the big picture. In this post I want to look at and compare actual line layouts, in particularly the I, U, S, and L layout. Let me give you an overview of the different options.

Line Layout Strategies – Part 1: The Big Picture

In flow shops, you have a production line of some sort. This may be an assembly line or a manufacturing line; this may be automatic or manual. In lean, you often hear about the famous U-line.

In flow shops, you have a production line of some sort. This may be an assembly line or a manufacturing line; this may be automatic or manual. In lean, you often hear about the famous U-line.

While this is a great solution, it may not fit all problems. Depending on the surrounding conditions, a different line layout may be beneficial. This post is the first in a series on line layout. In this post I would like to discuss what you should consider when designing a new line layout. The next post will look at actual line layout options.

Loss of Material: Theft!

Reddit: I am Chris Roser, a professor studying the past, present, and future of manufacturing, and just published my first book. AMA!

On September 27, I did my first Reddit: “I am a … ask me anything.” With almost four hundred comments, I consider it a quite successful AMA.

On September 27, I did my first Reddit: “I am a … ask me anything.” With almost four hundred comments, I consider it a quite successful AMA.

I am Chris Roser, a professor for production management; a lean expert; a Toyota, Bosch, and McKinsey alumnus; and I’m interested in the past, present, and future of manufacturing. I lived and worked for multiple years in the USA, in Japan, and in Europe. I run a blog, AllAboutLean.com, and just completed my first book, “Faster, Better, Cheaper” in the History of Manufacturing: From the Stone Age to Lean Manufacturing and Beyond.

Toyota’s and Denso’s Relentless Quest for Lot Size One

A famous step toward perfection in a lean production system is a lot size of one. However, few people realize what enormous effort and rigor Toyota applies to achieve this goal. During my visit to a Toyota plant and the APMS conference in Tokyo in 2015, I saw quite a few stunning examples of this quest. Let me show you …