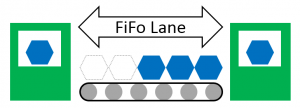

FiFo lanes are an important part of any lean material flow. They are a very simple way to define both the material flow and the information flow. In this post I want to tell you why to use FiFo, how to use FiFo, and the advantages of FiFo, as well as show you a few examples of FiFo lanes.

FiFo lanes are an important part of any lean material flow. They are a very simple way to define both the material flow and the information flow. In this post I want to tell you why to use FiFo, how to use FiFo, and the advantages of FiFo, as well as show you a few examples of FiFo lanes.

Christoph Roser

Corporate Culture on Quality Starts at the Top – A Small Anecdote on Organizational Blindness

Quality starts at the top with management. Top executives like to talk about quality, but employees below usually know very well if the manager only talks the talk or also walks the walk. Words are cheap. Quality (and pretty much everything else that is important) requires attention by management.

Facing Change in Modern Manufacturing Systems – The Difference between Flexible, Agile, Reconfigurable, Robust, and Adaptable Manufacturing Systems

The speed of modern business is continually increasing. Product life cycles of cars and mobile phones are decreasing, and customer demand is more volatile. Gone are the days of Henry Ford, who produced his Model T for almost 28 years without much change. Modern manufacturing systems need to be prepared for a constantly changing environment. The challenge has been realized for quite some time now, and there are a multitude of expressions related to this problem. This post will discuss many of these terms related to the challenge of change.

The speed of modern business is continually increasing. Product life cycles of cars and mobile phones are decreasing, and customer demand is more volatile. Gone are the days of Henry Ford, who produced his Model T for almost 28 years without much change. Modern manufacturing systems need to be prepared for a constantly changing environment. The challenge has been realized for quite some time now, and there are a multitude of expressions related to this problem. This post will discuss many of these terms related to the challenge of change.

The Hidden and not-so-hidden costs of Inventory

Inventory is one of the seven types of waste. There is usually quite a significant cost associated with having inventory, usually much more than what traditional bookkeeping accounts for. Between 30% and 65% of the value of your inventory is spent every year as inventory-related costs! This post looks into more detail at the cost of this inventory.

Manufacturing – A key stepping stone on the Road to Prosperity

Manufacturing is an important part of most economies. However, during the development of an economy, manufacturing plays different roles at different times. In fact, manufacturing is a key stepping stone on the road to economic prosperity. During the development from an agricultural society to a service society, nations must go at one point through a industrial society.

Manufacturing is an important part of most economies. However, during the development of an economy, manufacturing plays different roles at different times. In fact, manufacturing is a key stepping stone on the road to economic prosperity. During the development from an agricultural society to a service society, nations must go at one point through a industrial society.

The Bottleneck Walk – Practical Bottleneck Detection Part 2

The bottleneck walk is far and wide my most favorite method to detect bottlenecks on the shop floor (not only because it was developed by me, but also because it is really good!). You can detect shifting bottlenecks, using no math whatsoever and no time measurements, simply by walking along the production line and observing the line. It’s almost too easy to believe, but it works like a charm! Due to the length of this topic, I have broken the article into two posts. The first post “The Bottleneck Walk – Practical Bottleneck Detection Part 1” details how to find the current temporary bottleneck. This second post details how to determine the big picture regarding the bottlenecks. See below for a complete list of posts on this series on bottlenecks.

The bottleneck walk is far and wide my most favorite method to detect bottlenecks on the shop floor (not only because it was developed by me, but also because it is really good!). You can detect shifting bottlenecks, using no math whatsoever and no time measurements, simply by walking along the production line and observing the line. It’s almost too easy to believe, but it works like a charm! Due to the length of this topic, I have broken the article into two posts. The first post “The Bottleneck Walk – Practical Bottleneck Detection Part 1” details how to find the current temporary bottleneck. This second post details how to determine the big picture regarding the bottlenecks. See below for a complete list of posts on this series on bottlenecks.

Mathematically Accurate Bottleneck Detection 1 – The Average Active Period Method

This post describes an accurate way to detect the bottleneck in manufacturing systems, based on the average times a process is waiting or active. The method determines the primary bottlenecks in the system much more accurately than other methods commonly used in industry. The method was developed by me during my time at the Toyota Central R&D Laboratories in Japan. Subsequent posts look at other bottleneck detection methods that actually DO work!

This post describes an accurate way to detect the bottleneck in manufacturing systems, based on the average times a process is waiting or active. The method determines the primary bottlenecks in the system much more accurately than other methods commonly used in industry. The method was developed by me during my time at the Toyota Central R&D Laboratories in Japan. Subsequent posts look at other bottleneck detection methods that actually DO work!

The Bottleneck Walk – Practical Bottleneck Detection Part 1

The bottleneck walk is far and wide my most favorite method to detect bottlenecks on the shop floor (not only because it was developed by me, but also because it is really good!). You can detect shifting bottlenecks, using no math whatsoever and no time measurements, simply by walking along the production line and observing the line. It’s almost too easy to believe, but it works like a charm! Due to the length of this topic, I have broken the article into two posts. This first post details how to find the current temporary bottleneck. The second post details how to determine the big picture regarding the bottlenecks. See below for a complete list of posts on this series on bottlenecks.

The bottleneck walk is far and wide my most favorite method to detect bottlenecks on the shop floor (not only because it was developed by me, but also because it is really good!). You can detect shifting bottlenecks, using no math whatsoever and no time measurements, simply by walking along the production line and observing the line. It’s almost too easy to believe, but it works like a charm! Due to the length of this topic, I have broken the article into two posts. This first post details how to find the current temporary bottleneck. The second post details how to determine the big picture regarding the bottlenecks. See below for a complete list of posts on this series on bottlenecks.