Bottleneck detection and management are important when managing or increasing your production capacity. In the first post of this series, I talked about fundamentals and improving utilization. This second post looks at the impact of planning on the overall production capacity. A third post looks at Bottleneck Decoupling and Capacity Improvement.

Bottleneck detection and management are important when managing or increasing your production capacity. In the first post of this series, I talked about fundamentals and improving utilization. This second post looks at the impact of planning on the overall production capacity. A third post looks at Bottleneck Decoupling and Capacity Improvement.

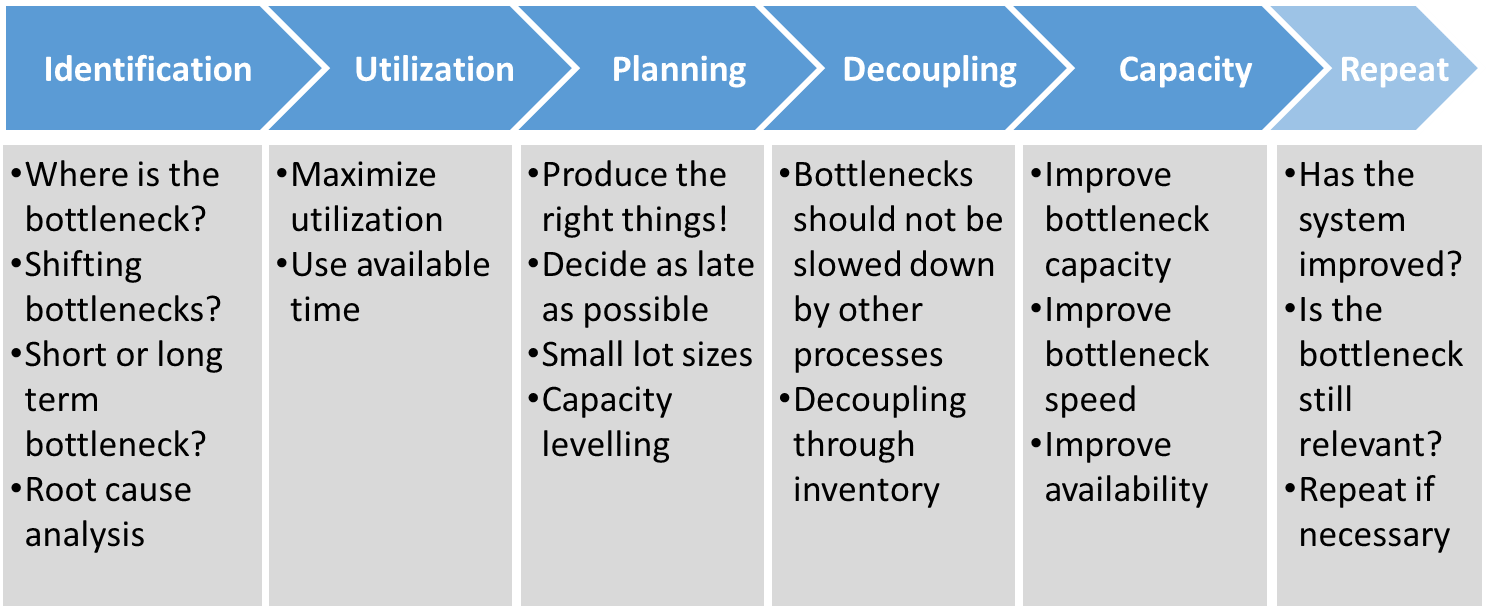

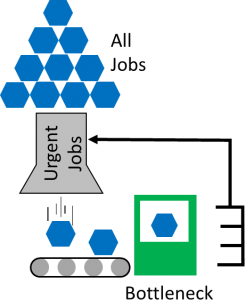

Just as a quick recap, below is the overall structure for bottleneck management. In this post we will discuss the impact of planning.

Planning and Material Flow

There are different ways in which the production plan of your system can influence the overall capacity. In the short term, you have to produce the right products. In the long term, you can level your capacity to cope with seasonal bottlenecks.

Use a Pull System

One key to maximizing the use of your bottleneck is to produce the right products. However, in most industries – and hence probably also in yours – the “right” product can change very quickly. Some customers may cancel orders. Other key customers may have a rush order. And, of course, most importantly, your boss can call anytime and tell you what is really important right now. Does this sound familiar?

In sum, what would have been the most urgent product yesterday may be totally different from what is the most urgent product today. Your production system needs to be agile enough to take these changes into account. Hence it is important to decide as late as possible what to use your bottleneck capacity for!

In sum, what would have been the most urgent product yesterday may be totally different from what is the most urgent product today. Your production system needs to be agile enough to take these changes into account. Hence it is important to decide as late as possible what to use your bottleneck capacity for!

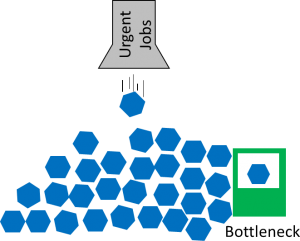

By its nature, jobs will accumulate in front of the bottleneck as the slowest process. If you have a push system, your tasks will accumulate in front of the bottleneck. Any prioritization you may have had when the job was added to the system is now long gone.

Hence, in a push system, you are more likely to produce the wrong products with a lower priority. Use a pull system to control your bottlenecks! Of course, in fact almost any manufacturing system will benefit from a pull system (using kanban or CONWIP or similar). However, it has special benefits for the bottleneck by deciding the priority only when the system actually has the capacity to do the work.

Hence, in a push system, you are more likely to produce the wrong products with a lower priority. Use a pull system to control your bottlenecks! Of course, in fact almost any manufacturing system will benefit from a pull system (using kanban or CONWIP or similar). However, it has special benefits for the bottleneck by deciding the priority only when the system actually has the capacity to do the work.

If your pull system produces only products made to stock through kanbans, it is automatically self-prioritizing. If you produce some custom-made products to order, then obviously you cannot keep them in stock. In this case the kanban is only a signal that a new order can be started. When such a signal comes, you should pick the most urgent job from the complete list of available jobs.

Use the Right Pull System

If you have a kanban system, then you are already past the first hurdle with bottlenecks. However, if your bottleneck does not shift very much, you can fine-tune the system. If there are multiple processes that make up your system, then there are different ways you can set up kanban loops. (See also my Ten Rules When to Use a FIFO, When a Supermarket).

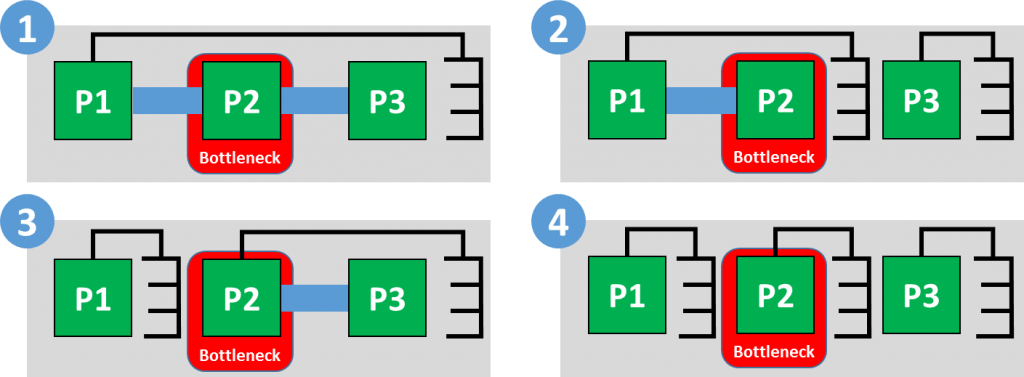

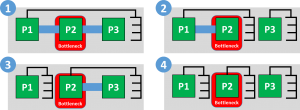

For example, in a system with three processes, you have four options how you could loop the kanban as shown below. You could make (1) one big loop, (4) three small loops, (2+3) or a medium and a small loop.

However, as for the bottleneck, you need to decide as late as possible what to produce. When the signal below comes from the customer, you need to get the signal to the bottleneck in the most direct way possible, and then get the product to the customer as fast as possible. Hence, out of the four options below, one is superior to the other ones. Granted, it is not a huge difference, but what do you think? Which of the four options below is best? See the end of the post for the answer with explanation.

Lot Sizes

Similarly, lot sizes can also influence the use of your bottleneck. In general, the smaller the lot size, the closer you can follow the customer demand. Naturally, if your changeover time is not zero, you may not want to change over too often. However, you also should not change over too rarely, as you may produce the wrong goods. (See also SMED for improving change over time.)

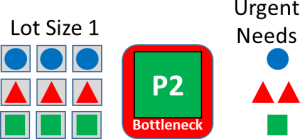

Assume the example on the left with a lot size of three. If you want to satisfy your urgent customer needs, no matter what you produce, you will produce some items that are not needed. If you produce red triangles, you will have one excess triangle with a lot size of three.

Assume the example on the left with a lot size of three. If you want to satisfy your urgent customer needs, no matter what you produce, you will produce some items that are not needed. If you produce red triangles, you will have one excess triangle with a lot size of three.

Similarly, if you produce blue circles or green squares, you will always have two circles or squares that the customer does not need. Yet with lot size three, you have to waste your precious bottleneck capacity for goods that nobody needs at that time.

Imagine the same example with a smaller lot size of one. Having exactly the same demand, now you can produce exactly what the customer needs and not a single piece more. You produce two triangles, one circle, and one square. Not one bit of your bottleneck capacity is wasted for a good that is not (yet) needed.

Imagine the same example with a smaller lot size of one. Having exactly the same demand, now you can produce exactly what the customer needs and not a single piece more. You produce two triangles, one circle, and one square. Not one bit of your bottleneck capacity is wasted for a good that is not (yet) needed.

Overall, a smaller lot size often allows you to produce closer to the actual customer demand, wasting less bottleneck capacity on producing goods nobody needs, just to reach your lot size.

Seasonality

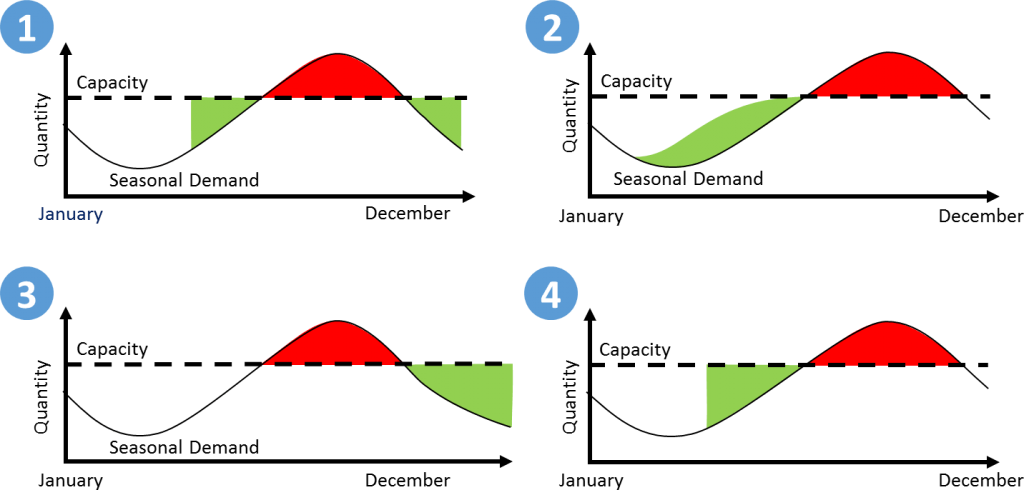

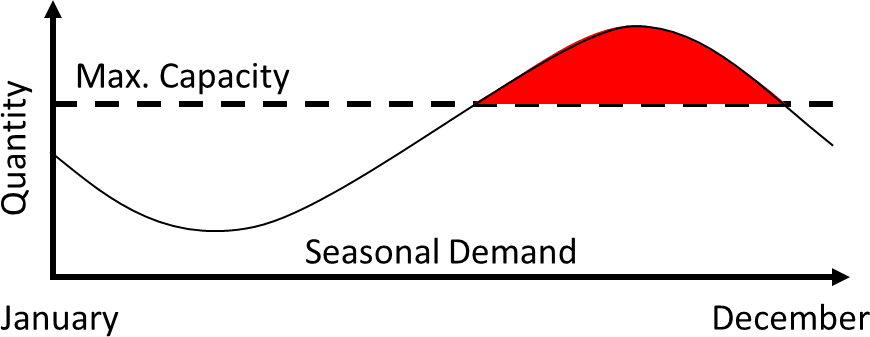

Many industries have seasonal customer demand. During some times of the year, the demand is high, but it is low at other times. The image below could be, for example, a winter sports manufacturer. Demand peaks in fall and early winter when people buy their gear for the upcoming winter season. Demand falls in spring and summer, when few people other than Australians buy their skis. (Australians love fun and sport, but there are just not enough of them to make up for the lack of demand in North America and Europe.)

If you are a winter sports manufacturer, you could invest in all the machines to have enough capacity for peak demand. However, this would be expensive. More commonly, there is not enough capacity to satisfy peak demand. Instead, the drop in demand is used to make goods that cannot be made during peak demand.

If you are a winter sports manufacturer, you could invest in all the machines to have enough capacity for peak demand. However, this would be expensive. More commonly, there is not enough capacity to satisfy peak demand. Instead, the drop in demand is used to make goods that cannot be made during peak demand.

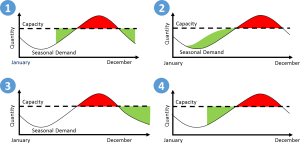

Below is another exercise with four options for how this seasonal demand can be handled using the available capacity during low season. In these examples, the lack of capacity (red) is made up before and/or after with available capacity (green). Of these examples, two is (usually) a very bad idea, one is troublesome, and one is my preferred approach. If you know which one is which and why, click here to jump to the answers at the end of this post.

On a side note, make sure you use the capacity outside of the peak season to produce your high runners, products that you’re sure will sell during season. If you produce exotics, you will have a harder time determining demand and a much higher risk of ether lacking or having leftover products during peak season.

In any case, planning and organizing your material flow will help you greatly in managing your bottleneck. Additionally, these methods above are usually not expensive (compared to simply buying a new machine) and can be implemented faster. Hence this is my second preferred approach to handling bottlenecks besides simply increasing utilization as described in the last post. In the next post I will talk about the more expensive and slower options of decoupling and adding capacity before closing this series of posts on bottleneck management.

Below are the answers to the exercises from above in case you haven’t yet read them.

Answer to the Exercises Above

Answer: Which Kanban Loop is Best

In the example above, option (3) is the best one. The kanban goes straight and without delay to the bottleneck. After the part passes the bottleneck, the part goes straight to the last supermarket and from there to the customer.

In the example above, option (3) is the best one. The kanban goes straight and without delay to the bottleneck. After the part passes the bottleneck, the part goes straight to the last supermarket and from there to the customer.

Option (4) is worse, since the signal from the customer has to pass the loop around P3 before reaching P2. Similarly, the part can potentially wait in the supermarket after P2.

Option (1) also takes more time. While the part goes from P2 to P3 and to the customer with minimal delay, the kanban loop includes P1 and hence takes longer.

Finally, option (2) is the worst, since the kanban first has to go through the entire loop of P3, and then through the big loop with P1 before reaching P2. After production, the part can potentially wait in the supermarket after P2.

Jump Back to the Question above.

Answer: How to Handle Seasonal Demand

Out of these four examples, option (2) is the best. But let’s start at the other end.

Out of these four examples, option (2) is the best. But let’s start at the other end.

Option (3) is probably the worst, since the season is already way over when you have your goods. Not only did you miss sales, but you also have to rent warehouse space for the goods till next season. (Please note that there are, as always, exceptions, as, for example, some high-tech industry monopolists can afford to have the customer wait on their goods, in which case (3) is viable again.)

Option (1) is little better. You have some goods made to stock before the season, which you can sell off during the season. However, some more goods after the season will have the same problem as option (3), being too late for this season and too early for the next.

Option (4) looks good at first glance. You minimize your inventory with option 4. However, in many cases you will break your supply chain. First, your entire organization has to double its output within a few days. While you have the machine capacity, you may have to stretch a bit for the manpower, but this is doable. What will break, however, are your suppliers.

It is not only you that will have to make this jump, but your entire supply chain. In all likelihood someone will either mess up or consider you not important enough to care. (In case you ask your supplier if you are important, of course you are the most important customer for them, just like all other customers. Just consider how you talk about some of your customers at the water cooler.)

Hence you will probably get most of the material you need, but not all. Unfortunately, if only one part is missing, you cannot produce. You will miss your production window because one part is missing, and at the same time you have to store all the other parts that arrived on time. That sucks!

Naturally, there are some exceptions to this too. If you are a small company and/or using only generic parts, your suppliers won’t even notice you doubling your output. Hence this may just work. Or if you have complete control over your supply chain, say as a brick maker with its own clay pit. But anybody else should think twice before testing the breaking point of their supply chain.

This brings me to my preferred option (2) above. It is similar to option (4), but with a gradual increase. Your supply chain has a chance to catch up. Additionally, you may be able to produce a bit more if your demand forecast improves. Overall, it will be much smoother sailing for most companies.