Many topics in lean address how to deal with uncertainty and fluctuations (or mura for unevenness). There is a particularly neat trick for manual lines that self-organizes fluctuations in the workload: the Bucket Brigade (also known as bump-back or bouncing line)! It does have some advantages, but it also has quite a few limitations and prerequisites for it to work. Most importantly it works best only for very short cycle times as for example picking materials. Unfortunately, these requirements are rarely mentioned in literature. Let me show you the basics work in this post before I go into some of the trickier details in the next post.

Many topics in lean address how to deal with uncertainty and fluctuations (or mura for unevenness). There is a particularly neat trick for manual lines that self-organizes fluctuations in the workload: the Bucket Brigade (also known as bump-back or bouncing line)! It does have some advantages, but it also has quite a few limitations and prerequisites for it to work. Most importantly it works best only for very short cycle times as for example picking materials. Unfortunately, these requirements are rarely mentioned in literature. Let me show you the basics work in this post before I go into some of the trickier details in the next post.

Examples for Transport

The term bucket brigade originally comes from firefighting, and is in general used for transportation using a human chain. People create a human chain by standing approximately 1 meter apart. Goods are transported by handing them from person to person. This could be, for example, buckets of water (in case of a fire), empty buckets (also in case of a fire, to refill the buckets), boxes for loading and unloading, or any other type of goods. The image below shows a bucket brigade handling cleaned bricks for reuse in Germany shortly after World War II.

The advantage of the bucket brigade is that there is little walking involved. Rather than walking back and forth with an bucket, a person stays on the spot and merely hands the items to the next person. An additional benefit is that there is a fast cycle of holding a load and not holding a load, which is less strenuous than holding a load for a long time followed by a long break.

Bucket Brigade in Lean Manufacturing

The term bucket brigade made it into lean manufacturing, although the name does not exactly fit well in my opinion. A bucket brigade in lean manufacturing DOES indeed involve walking. The advantage of a bucket brigade is to avoid waiting times for operators in the case of uneven workload.

Prerequisites

For a bucket brigade to work, you have a few prerequisites. Strictly speaking, they are not all necessary, but it makes things much easier.

For a bucket brigade to work, you have a few prerequisites. Strictly speaking, they are not all necessary, but it makes things much easier.

- Short cycle times: Short cycle times reduce waiting times during the hand-over of the part and avoid trickier in-process hand-overs. This is actually a requirement that makes the use of this bucket brigade difficult for many flow lines (more on this in my next post). In fact, most practical examples are in pick-and-place or commissioning of materials due to the short process times.

- Manual flow line: A bucket brigade works only for a flow line, not for a job shop. There must be a clear and identical sequence of steps for all parts passing through the system. It also helps if the processes are manual processes, where the operator does not have to wait for a machine.

- More processes than workers: A bucket brigade requires more process steps than workers. The workers are shifting between different processes to balance the uneven workload.

- All workers trained in all processes: Since the workers move between different stations, they should all be trained in how to operate every process. Okay, to be precise, only the first worker would need to know the first process and the last worker the last process, but all workers would need to know all processes in between the first and the last process.

- Processes nearby: The farther away the processes are, the more difficult it will be to operate the bucket brigade.

- Uneven workload: The bucket brigade is well suited to balance out uneven workload. If the workload is even, you don’t need a bucket brigade (although it would still be possible). Relevant here is not the average workload, but the short term workload. In other words, if randomly one part may be faster or slower than the average, you have an uneven workload. Most processes I have seen do have somewhat random uneven workloads.

- Bottleneck at the beginning: For the bucket brigade to work properly, the first processes should be the slowest. You need to have an increasing speed along the line. The first processes should be slower, and the last processes faster. Alternatively, you can put the slow worker at the beginning and the fast worker at the end of the line – although this selection can give you labor problems by calling a worker “slow” (more on this in my next post).

- No buffer inventories: Buffer inventories combined with bucket brigades can lead to quite inefficient waiting times (more on this in my next post).

How It Works: The Common Way

For a “normal” bucket brigade, there are three rules for an individual worker. The worker gets the part from the preceding worker and then moves with the part along the line until he can give the part to the next worker.

1: Receive part from preceding worker

Any worker on the line can get a new part, either from the preceding worker or from the inventory at the start of the line. Hence, an idle worker walks back along the line until he meets the preceding worker (or the start of the line). The worker then takes over the part from the preceding worker.

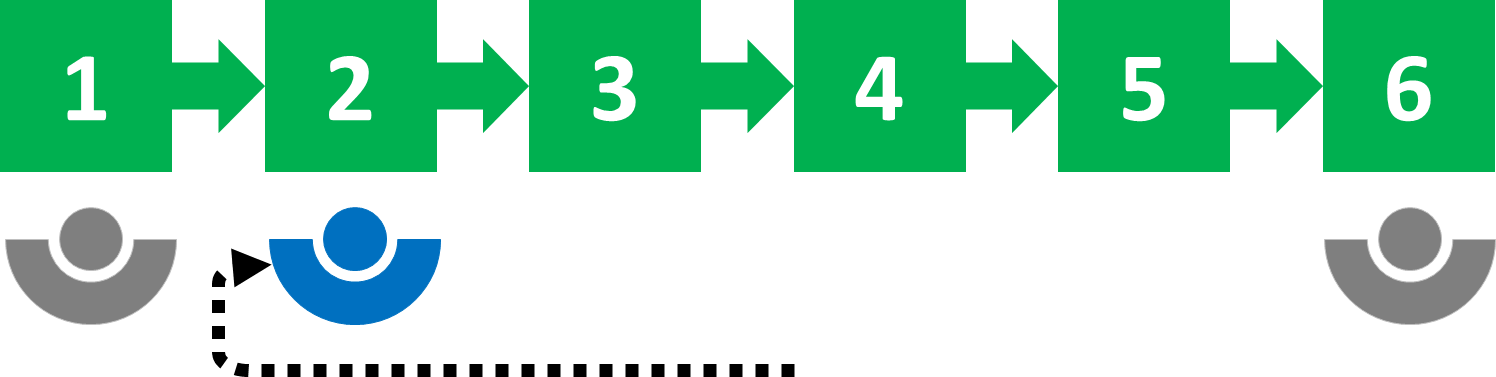

In the image below, the blue worker walked back along the line until he met the worker at station 1. The blue worker takes over the part from the preceding worker. Here we have two possibilities. Either the preceding worker just finished his part at station 1 and can give it to us right away, or the preceding worker is still working on the part at station 1. In the latter case, we could either wait for worker 1 to finish or take over while the part is still in process 1.

As you can imagine, taking over the part halfway throughout the process is risky, as it requires good communication to know exactly what is already done and what still has to be done. I will talk about these problems a bit more in the next post.

2: Move along the line with a part

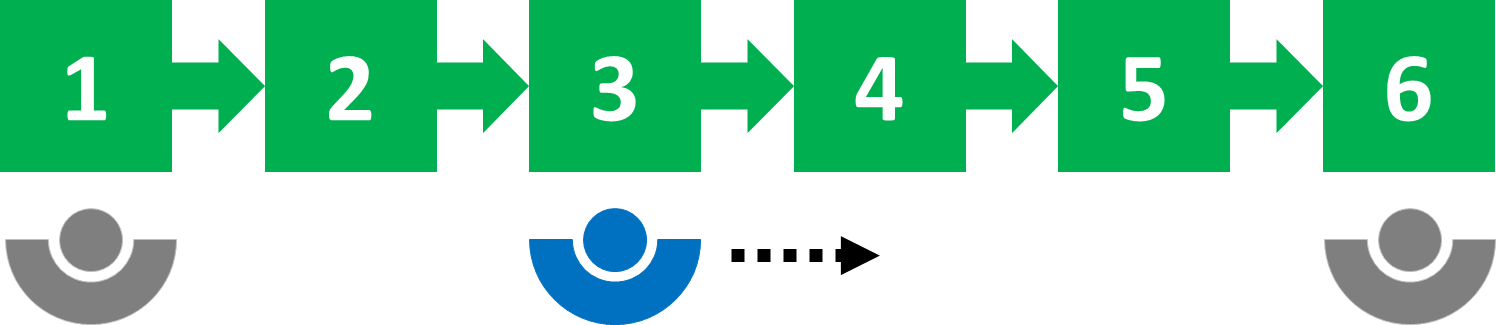

After the worker receives a part, he walks along the stations as he processes the parts in the sequence of the stations. In other words, when the part is completed at this station, the worker moves the part to the next station and processes the same part in the next station. For example, in the image below you see a blue worker at station 3. After the worker completed processing of the part at station 3, he moves with the part to station 4 and processes the same part at station 4.

3: When you meet your next colleague

Sooner or later the blue worker will meet the subsequent worker (or the end of the line). If it is the end of the line, the worker will store the part (e.g., in a box) and walk back along the line.

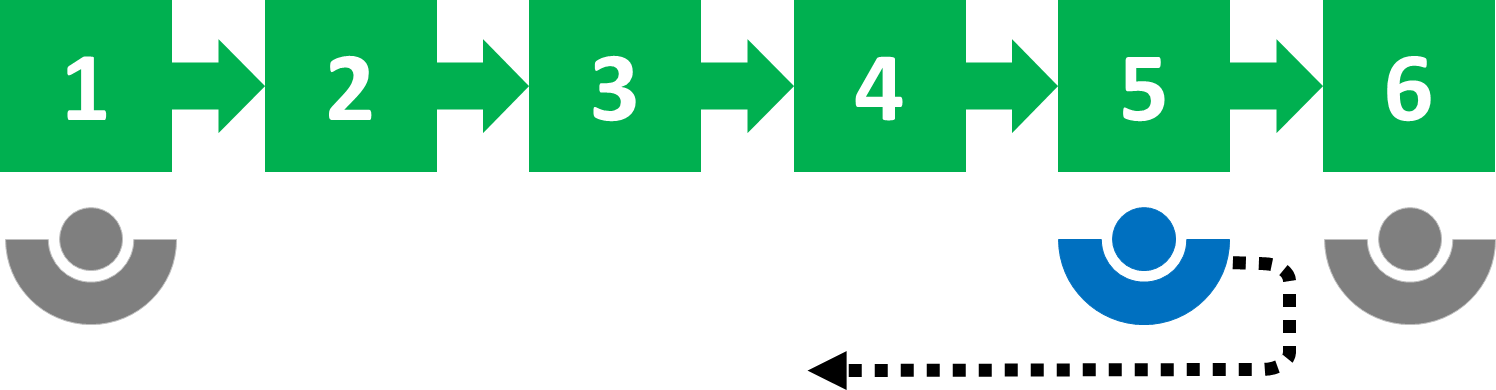

If it is the next worker, the worker will give the part to the next worker and walk back along the line. For example, the blue worker below at station 5 meets the next worker at station 6. He then hands over the part to the next worker and walks back along the line.

There is a slight complication here. It depends on whether the next worker is walking back without a part (good) or if the next worker is still busy with a part (not so good). Ideally, the next worker is currently working back along the line and can take the part right away.

It is a bit more tricky if the next worker is still busy. In this case, the blue worker should wait or (if he can) help the next worker. Only when the next worker has given his own part to the subsequent worker or to the end of the line can the subsequent worker take over the part from the preceding worker. I will talk about this situation a bit more in my next post.

Summary

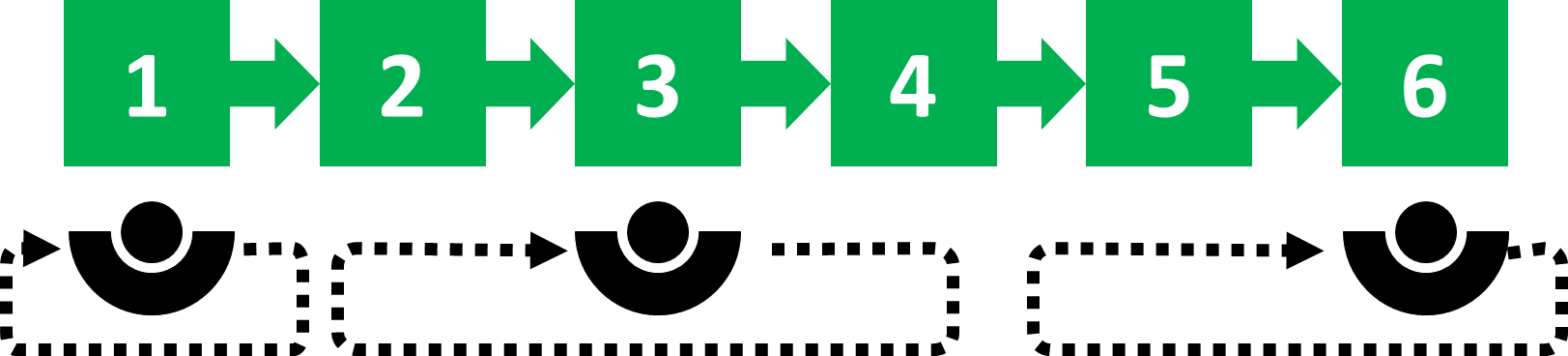

Overall, each worker will work in loops. The size of the loop is not fixed. If a worker has stations with a busy workload or encounters a problem, his loop will automatically become smaller and the loops of the other workers bigger. For example, in the images below, if process 3 temporarily becomes slower, the other two workers will have bigger loops, hence the worker in the middle can take more time to work on process 3.

Overall, the workers always move back and forth between the preceding worker (or the start of the line) and the succeeding worker (or the end of the line). Note that the fastest worker is at the end, and the slowest at the beginning. Also note that the workload of the first two workers changes over time.

Of course, there are still lots of details that need to be taken care of. I will talk more about this in the next post. In the meantime, go out and organize your industry!

Very interesting and well explained Christopher, Seems as if the energy of motion of the workers to pick up the finished product at the earliest time possible is compensating for the wasted waiting time that would result if they remained stationary. So we have a reduction in over all cycle time however total work ( energy ) used by workers is increased. Somewhat like an example of the 1st law of thermodynamics… Thank you for sharing this.

Your post-WW-II picture reminded me of a story I heard long ago about a hotel guest in Germany complaining about hearing trains all night. “But there is no railroad near here,” said the innkeeper. Walking out, the guest saw a line of people passing bricks to each other, saying “Bitte schön, danke schön, bitte schön, danke schön,….”

Hi Michel, “Danke schön” for the comment 🙂

I’m a line operator myself. A bit late to the party, but this post sounds like an overly formalistic way to describe good old-fashioned teamwork. All but one of our production lines are pretty small and any operator can just look around and see where things are moving along smoothly and where things are getting backed up. To complicate matters, not all stations are evenly balanced and a bunch of them require a very variable amount of time to do the standard work from unit-to-unit (simply due to the nature of our business rather than poor process design). Of course, if I have no WIP and the guy after me is backed up, I grab the tools and help them out. We also have major staffing issues right now, so it’s not uncommon to have one operator drive two or three adjacent stations in the manner described in this post.

Hi Andre, if the operator simply moves where he thinks he is needed, he may be sometimes wrong. This bucket brigade is a structure to keep all employees busy and the productivity high. See Chaku Chaku line and Rabbit Chase for other examples.

Thank you for replying to all the comments I’ve been leaving. I’m still learning a lot of this stuff. As I mentioned, if the preceding stations are running and I have work to keep me busy, then I stay at my station and do the work. Like I said, on most of the lines we have, it’s easy to see the entire line from any one of the stations on it. Of course I keep a close eye on mine if I’m helping someone else. As soon as I see a unit about to land on my station, I just tell the other guy “sorry, gotta go”.

Now, when we have more stations than operators, then we work just like you’ve described. Every operator is busy working their unit down the line until they meet someone who can take it and quickly go back up the line until they find work to do.

Sounds good. I am also still learning, too, and writing a blog is (not always but sometimes ) sort of my “homework” 🙂

Hi Christoph,

thanks for these very informative blog posts you share! I’ve learned a lot from them.

recently we implemented bucket brigade (or bounce back as we call it) concept in our garment manufacturing lines. There were few benefits such as, the absenteeism had minimum effect on the line flow (yes the output was low! but the line never stooped) , very less WIP etc..

However, we saw some negative impacts also. Main issue was the problems didn’t surfaced and it was slowly disrupting our problem solving culture at the line. The team members complained that when they are skilled, they get more work and others could just wait.

So, We’ve decided to go ahead with ‘fixed work cycle’ method rather than bounce back. Any thoughts from your experience?

Also we could not figure out a way to do the Yamazumi when they bounce back! Any thoughts on that?

Interesting. I think the Yamazumi chart is less important in a bucket brigade. But the workers feelings you mentioned are relevant. If someone is intentionally slacking off, then you should take action. More likely is, however, that the faster worker feels it is unjust to produce more for the same money. You should talk with him, and tell him that if the work is distributed evenly, he (the faster one) would have lots of waiting times for the slower worker. Overall, I would try to get the workers on my side and understand that it is smoother for everybody.

Hi Christoph,

In pharma industry, we have short cycle times to packaging products usually we use automated systems but often we pack products manually. In my case my pacemaker is 65 Units/min but we pack the units manually so we use two workers in sequence to do it. first worker pack 12 units in a box and he/she lets pass the next 12 units for the second worker and so on. What would be your recommendation. Use unstructured or pulse line to timing the line?

Thanks

Hi Rene, it sounds that you do not have a packaging *line*, but two parallel process working independently. If they are directly connected to the production line, then the timing is determined by the main production line and would probably be pulsed or even a continuously moving line. Packaging is just another process at the end of this line. If they are separate, i.e. with a larger buffer and/or delay between the production and the packaging, then unstructured may be best. It would be difficult to get a time signal to manual workers on their own.