In my series of posts on the Toyota KPI dashboard I went into detail about the different sections and KPIs. These dashboards work well fro Toyota. However, this does not mean that they automatically work well for you too. Chances are, you are not making cars. Even if you are, your relevant KPI information may be different from Toyota’s. Let’s have a look…

In my series of posts on the Toyota KPI dashboard I went into detail about the different sections and KPIs. These dashboards work well fro Toyota. However, this does not mean that they automatically work well for you too. Chances are, you are not making cars. Even if you are, your relevant KPI information may be different from Toyota’s. Let’s have a look…

Toyota

Any posts related to companies from the Toyota Group, including Toyota Motor, Denso, etc., and its people.

The Toyota KPI Dashboard—Production Plan

In my previous posts I went into great detail through all the categories of the Toyota KPI dashboard: safety, quality, productivity, and cost. I also explained the additional section on HR development, albeit this may not really be KPI in the normal sense. However, the dashboard often contains even more: a section with the monthly production plan, a section for the allocation of the operator, and different A3s for improvement. Lets dig deeper:

In my previous posts I went into great detail through all the categories of the Toyota KPI dashboard: safety, quality, productivity, and cost. I also explained the additional section on HR development, albeit this may not really be KPI in the normal sense. However, the dashboard often contains even more: a section with the monthly production plan, a section for the allocation of the operator, and different A3s for improvement. Lets dig deeper:

The Toyota KPI Dashboard—Human Resources

With the KPI groups safety, quality, productivity, and cost, this series on the Toyota KPI dashboard has covered the main topics. However, there is more. Not always but often you can also find a section on human resources (HR) development. Yet, these are usually not KPI, but more organizational topics that may be part of the daily shop floor meeting. Below are some examples of how this section could look, although this may vary quite a bit among different Toyota plants. Let’s have a look:

With the KPI groups safety, quality, productivity, and cost, this series on the Toyota KPI dashboard has covered the main topics. However, there is more. Not always but often you can also find a section on human resources (HR) development. Yet, these are usually not KPI, but more organizational topics that may be part of the daily shop floor meeting. Below are some examples of how this section could look, although this may vary quite a bit among different Toyota plants. Let’s have a look:

The Toyota KPI Dashboard—Cost

In my series on the Toyota KPI dashboard, after safety, quality, and productivity, we finally arrive at cost. While for some companies it is the number one factor, for Toyota it is far behind safety, quality, and productivity. The argument is that if safety, quality, and productivity are in line, it is likely that cost is also good. Both a lack of quality and a lack of productivity will drive up the cost.

In my series on the Toyota KPI dashboard, after safety, quality, and productivity, we finally arrive at cost. While for some companies it is the number one factor, for Toyota it is far behind safety, quality, and productivity. The argument is that if safety, quality, and productivity are in line, it is likely that cost is also good. Both a lack of quality and a lack of productivity will drive up the cost.

The Toyota KPI Dashboard—Productivity

This post in my series on the Toyota KPI dashboard looks at productivity. After safety and quality, this is the third-most-important KPI group on the Toyota dashboard. The cost is least important. This section of the dashboard measures different KPIs on the productive output of the system. Let’s have a look.

This post in my series on the Toyota KPI dashboard looks at productivity. After safety and quality, this is the third-most-important KPI group on the Toyota dashboard. The cost is least important. This section of the dashboard measures different KPIs on the productive output of the system. Let’s have a look.

The Toyota KPI Dashboard—Quality

In this third post of my series on the Toyota dashboard we will be looking in more detail at quality. The quality of Japanese car makers in general and Toyota in particular is quite a bit better than the rest of the world’s. After safety, quality is the second-most-important issue at Toyota, definitely before productivity and cost. They do put in quite some effort for tracking quality… and then put in even more effort to fix these issues! Let’s have a look:

In this third post of my series on the Toyota dashboard we will be looking in more detail at quality. The quality of Japanese car makers in general and Toyota in particular is quite a bit better than the rest of the world’s. After safety, quality is the second-most-important issue at Toyota, definitely before productivity and cost. They do put in quite some effort for tracking quality… and then put in even more effort to fix these issues! Let’s have a look:

The Toyota KPI Dashboard—Safety

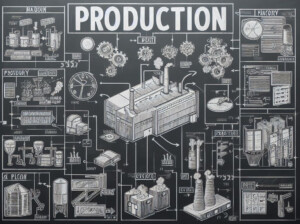

The Toyota KPI Dashboard—Overview

Dashboards, in their many forms, are essential to track the performance of a production system. In this post I will talk more about the Toyota shop floor dashboard. A lot of the information is from Toyota in Japan, but the images are from Toyota UK. Keep in mind that the dashboards are not a rigid standard and there may be differences in how they are implemented in the different plants. For one thing, in Japan they are in Japanese, and in the UK in English, but there are also differences within the KPI itself. Let me tell you more in this short series on the Toyota KPI dashboards…

Dashboards, in their many forms, are essential to track the performance of a production system. In this post I will talk more about the Toyota shop floor dashboard. A lot of the information is from Toyota in Japan, but the images are from Toyota UK. Keep in mind that the dashboards are not a rigid standard and there may be differences in how they are implemented in the different plants. For one thing, in Japan they are in Japanese, and in the UK in English, but there are also differences within the KPI itself. Let me tell you more in this short series on the Toyota KPI dashboards…