This post is the third in this series on how Toyota plans standard work. The first one was the production capacity sheet to define what capacity you have available. The second one was a standard work combination table to define when the operator is doing what. Finally, the third of the “famous three slips”, presented in this post, is a standard work layout sheet to help the layout and arrangement of the machines.

This post is the third in this series on how Toyota plans standard work. The first one was the production capacity sheet to define what capacity you have available. The second one was a standard work combination table to define when the operator is doing what. Finally, the third of the “famous three slips”, presented in this post, is a standard work layout sheet to help the layout and arrangement of the machines.

Toyota

Any posts related to companies from the Toyota Group, including Toyota Motor, Denso, etc., and its people.

Toyota Standard Work – Part 2: Standard Work Combination Table

Toyota has a nifty way to plan the work of an operator using their standard work charts. In my last post I explained the production capacity sheet to define what capacity you have available. In this post we will talk about the second of the “famous three slips”, the standard work combination table to define when the operator is doing what. A subsequent post will show a standard work layout sheet.

Toyota has a nifty way to plan the work of an operator using their standard work charts. In my last post I explained the production capacity sheet to define what capacity you have available. In this post we will talk about the second of the “famous three slips”, the standard work combination table to define when the operator is doing what. A subsequent post will show a standard work layout sheet.

Toyota Standard Work – Part 1: Production Capacity

Toyota is excellent with their standard work. They use a series of worksheets to simplify the creation of these standards. These are sometimes also know as the “famous 3 slips”. The first one is a production capacity sheet to define what capacity you have available. The second one is a standard work combination table to define when the operator is doing what. The third one is a standard work layout sheet to help with the layout and arrangement of the machines. While there are many different ways of doing this, I like the Toyota approach. Since this is a larger topic, I’ve broken it into multiple blog posts. Lets start with the Production Capacity sheet.

Toyota is excellent with their standard work. They use a series of worksheets to simplify the creation of these standards. These are sometimes also know as the “famous 3 slips”. The first one is a production capacity sheet to define what capacity you have available. The second one is a standard work combination table to define when the operator is doing what. The third one is a standard work layout sheet to help with the layout and arrangement of the machines. While there are many different ways of doing this, I like the Toyota approach. Since this is a larger topic, I’ve broken it into multiple blog posts. Lets start with the Production Capacity sheet.

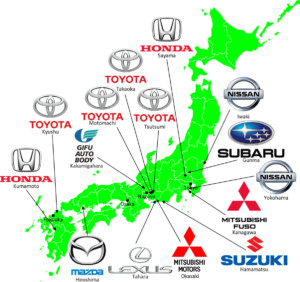

The Grand Tour of Japanese Automotive – Overview and Toyota

During Winter 2017–2018, I spent five months in Japan. As part of this visit, I was able to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive Plants.

During Winter 2017–2018, I spent five months in Japan. As part of this visit, I was able to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive Plants.

This was extremely insightful, and I learned a lot about the differences between the Japanese car makers. Let me give you an overview and some details on Toyota plants before firing off a series of blog posts on the different Japanese automotive companies.

Continued Evolution of the Toyota Assembly Line

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

The Toyota Employee Evaluation System

Anatomy of the Toyota Kanban

While Toyota did not invent the pull system, they did invent kanban, the genius idea of using cards of paper (and later other forms of information) to create a pull system for mass-produced goods. I recently was able to take pictures of Toyota kanbans, and would like to show and explain them to you.

While Toyota did not invent the pull system, they did invent kanban, the genius idea of using cards of paper (and later other forms of information) to create a pull system for mass-produced goods. I recently was able to take pictures of Toyota kanbans, and would like to show and explain them to you.

Karakuri Kaizen Examples

After an introduction and description of the fundamentals of karakuri kaizen, here are some different karakuri kaizen examples for a wide variety of uses. Most of them are from the 480 exhibits at the the Karakuri Kaizen Exhibition 2017 in Nagoya, Japan; others are from the 2017 OPEXCON in Stuttgart, Germany. Here is my attempt of a structured overview, even though some of the points below may be overlapping.

After an introduction and description of the fundamentals of karakuri kaizen, here are some different karakuri kaizen examples for a wide variety of uses. Most of them are from the 480 exhibits at the the Karakuri Kaizen Exhibition 2017 in Nagoya, Japan; others are from the 2017 OPEXCON in Stuttgart, Germany. Here is my attempt of a structured overview, even though some of the points below may be overlapping.