As the name says, this site is all about lean manufacturing. But, what is lean? How do we define lean manufacturing? After all, since most of industry talks about lean, we should have a definition to make sure that we’re all talking about the same thing. Unfortunately, a) we do not have a good definition of lean, and b) not everybody means the same thing when they talk about lean. So, what could lean manufacturing mean? Let’s have a look at the different definitions out there:

The Origin of the Term “Lean”

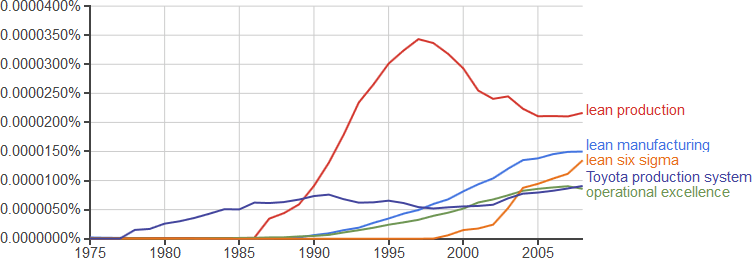

English language publications started to note the Toyota Production System around 1975. Soon thereafter, the term “Lean Production” was coined by John Krafcik in his 1988 article, “Triumph of the Lean Production System,” and it has been used in industry ever since. After a slight delay, the term “Lean Manufacturing” also appeared.

From 1998 onward, Six Sigma also took on the term “Lean Six Sigma,” although in my opinion they did not really add anything valuable to it. Nowadays, “Operational Excellence” is pushed as a replacement for the aging term “Lean Production,” although I still prefer lean. The chart below gives you an overview on how often the words are used in literature (Data from Google Ngram viewer)

Selection of Lean Definition

But what does Lean manufacturing mean? Below are some definitions of lean found in literature and the web. In pretty much all instances there would be many more similar definitions out there. However, for the sake of brevity, I usually cite only one or two of them.

Lean is Whatever Toyota Does!

Lean manufacturing is the term most commonly used to describe the Toyota Production System (TPS). (emsstrategies.com)

"Lean" is the set of management practices based on the Toyota Production System (TPS). (Mark Graban Lean Blog)

Well, these definitions are mostly correct. Pretty much everything we do in lean is a (rarely better, often worse) copy of the Toyota Production System. The Western world added a few new aspects to lean, but very few of them are actually useful (see, for example, how the original seven types of waste from Toyota bloomed into up to 31 types of waste).

However, while the definition is correct, it is of little use. For one thing, what is good for Toyota is not necessarily good for everybody. Toyota is a mass-producing auto company. If a small custom-made machine tool maker would use methods identical to Toyota, it would be anything but lean, and the methods would probably kill the company.

Secondly, while it is okay to say that lean is whatever Toyota does, it does not help at all in figuring out what exactly Toyota does! But luckily, here are a few more lean definitions for you:

Lean is 5S, SMED, Kanban, JIT, … !

This is (luckily) not a definition I have found written down. Unfortunately, when talking with people in industry and academia, all too often it feels like that is some people’s definition. “I’ll just do kanban and JIT, and then I will be lean. Or better, I’ll have somebody else do it for me.”

Lean is not just a set of different tools. Just as a car is not just a pile of parts. Michelangelo was not just someone with a chisel. It is the art of using these tools that makes production lean.

While the reduction of lean production on its tools is luckily not an official definition, the reduction on one tool is unfortunately all too common: waste elimination!

Lean is Elimination of Waste!

Lean manufacturing or lean production, often simply "lean," is a systemic method for the elimination of waste ("Muda") within a manufacturing process. (English Wikipedia, but also similar on French, Portuguese, and Dutch Wikipedia)Lean manufacturing involves never-ending efforts to eliminate or reduce [waste] in design, manufacturing, distribution, and customer service processes. (BusinessDictionary.com)

Defining “lean” as reducing waste is actually surprisingly common. Of the definitions I have come across, most are using waste elimination to define lean. Maybe it’s because of the word “lean” itself, which, among other things, means “containing little or no fat.“

However, reducing lean production solely to elimination of waste is in my view also far too short-sighted. Lean production is so much more than simple elimination of waste.

Lean is Fast, Efficient, and High Quality!

Lean Production refers to the both economical and time-efficient use of factors of production resources, personnel, materials, planning, and organization in the context of all company activities. (Gabler Wirtschaftslexikon, translated by me)

Defining lean as being fast, efficient, and high quality is just the other side of elimination of waste. Besides, how do you, using this definition, distinguish lean from other types of production systems? Pretty much every manufacturing entity since the dawn of time aimed to be efficient.

For example, Henry Ford’s assembly line also was geared toward efficient use of resources and time through relentless elimination of waste. Therefore, defining lean through efficiency and waste elimination would mean that Henry Ford invented lean production. While Ford certainly contributed to the ideas at Toyota, he did not have a lean production system!

Lean is Flow!

Lean manufacturing is a management model focused on creating flow to deliver maximum value for customers, using the minimum resources necessary. (Spanish Wikipedia, translated by me)

Another concept often associated with lean is the idea of optimizing the flow of material. This is also found at least partially in many definitions of lean. While it is an important aspect of lean, it is in my view also far short of the true ambitions and values of lean production. Similar to waste elimination or efficiency, one aspect of lean is not enough to define lean.

Lean Is a Culture!

In discussion with other practitioners, yet another set of definitions tries to define lean as a culture. It certainly is a culture, but it becomes rapidly fuzzy when one tries to define what kind of culture it is. Defining the culture of lean inevitably falls back to any of the above definitions of eliminating waste, increasing value, or adding flow.

Lean is Adding Customer Value

The core idea is to maximize customer value while minimizing waste. (LEI Institute)

Lean is the permanent struggle to flow value to one customer. (Mike Rother)

Yet another set of definitions goes toward adding customer value. While I like the customer as part of the definition, he is certainly not the only stakeholder. The latter definition by Mike Rother also includes flow, and importantly, the element of continuous improvement. However, again we find the focus on eliminating waste in order to create value.

Even including continuous improvement, flow, and elimination of waste (or in Japanese kaizen, mura, and muda), we still fall far short of what lean really is. For example, in none of the definitions above have I found the elimination of unreasonableness, which is the third of the three evils of manufacturing. Also the entire concept of respect for people is missing completely.

How Toyota Defines TPS

Well, after all these sometimes-better, sometimes-worse attempts by Westerners to define lean, we can only agree that it came originally from Toyota, although this does not help us. Well, let’s have a look at how Toyota defines its own Toyota Production System. I found the following three definitions by Toyota themselves.

A production system which is steeped in the philosophy of "the complete elimination of all waste" imbuing all aspects of production in pursuit of the most efficient methods. (Toyota Global)

The first definition is the basic “eliminate waste” definition that we have seen many times above, nothing new here.

The practical expression of Toyota's people and customer-oriented philosophy is known as the Toyota Production System (TPS). (Toyota Australia)

The second definition not only has customers included, but also its own Toyota people. I like that. However, as for the definition of the Toyota Production System, even Toyota says that it is whatever Toyota does.

The Toyota Production System is built on two main principles: "Just-In-Time" production and "Jidoka." Underlying this management philosophy and the entire Toyota production process is the concept that "Good Thinking Means Good Product." (Toyota Georgetown)

The third definition uses the two main pillars of the Toyota Production System: JIT and Jidoka (Autonomation). However, in my view, these are only two aspects of the whole Toyota Production System. It seems even Toyota does not agree on its definition of the Toyota Production System.

Besides, from my point of view, they are not even the most important ones. I believe they are the pillars of Toyota because these two originate from the Toyoda clan, and not one of its employees like Taiichi Ohno. My gut feeling is that Toyota likes to praise its own bloodline and is working on legend building.

So Which Definition is Right?

Good question. Just as an iterative brain teaser, here is the definition of definition:

Definition (nounˌde-fə-ˈni-shən\): a statement that describes what something is.

To define something, you would need to make the definition clear enough to distinguish it from other similar things. However, most of the definitions above clearly fail at distinguishing it from almost all other production systems. Most of them would be, for example, perfectly valid for Henry Ford and his assembly line, or pretty much any production system developed after the Industrial Revolution.

Additionally, none of the above definitions really include the respect for people, which I consider one of the important elements of lean. Other important concepts like reducing unevenness (mura) and overburden (muri) are also missing. Therefore, in my view, none of the above definitions really capture the essence of the Toyota production system and lean production.

The Blind Men and the Elephant

Overall, it reminds me of the fable of the blind men and the elephant. A group of blind men touch an elephant to learn what it is like. Each one feels a different part, and in the end they disagree completely on what an elephant really is.

Conclusion: The Definition of Lean Production

Okay, now that I have criticized all the other definitions above, it is time for my own definition … except …

I don’t have one!

Gosh, that’s embarrassing! Despite my 20+ years of experience in lean, I cannot come up with a definition that I feel comfortable with. Whenever I try I just come up with something similar to the many definitions above. And whenever I add respect for others, it sounds cliché.

After all this lengthy discussion, we only find out that we have no good definition! Most definitions are too detailed about some methods that – except for their modern Japanese names – have been known a long time. The rest is too fuzzy and vague and reads like a typical company mission statement (which in general says “do good” using fancy words while trying not to offend anyone). However, my overall conclusion on this mess of definitions is pretty clear:

We haven’t understood yet what lean production really is!

We don’t know what is meant by lean manufacturing. We don’t know the meaning of lean. Probably all the difficulties we have in implementing lean production and all the failed projects with only a few successes in between probably stem from this lack of understanding. Even people who instinctively do things right have a hard time explaining it to other people. It is somewhat comforting that while Toyota does it right, even they cannot define it well.

In any case, I hope I have not confused you too much with this mess of definitions. Now go out and organize your industry, even though you may not be able to define what you are doing 🙂 .

P.S.: The idea for this post was initiated by an e-mailed question by Troels Andersen (Differience Consulting, Copenhagen, Name mentioned with permission). By the way, if you have a question related to lean, feel free to ask me!

So much has been written and defined about Lean it seems to never end! The problem that I see it that instead of reinventing Leam, just practice it. Some years ago some of my colleagues visited the Toyoat Plant here in the U S. When they returned they were so amazed by the TPS that they were going to copy it in their plant. The people at Toyota stated that they need NOT copy what they do, but observe the “Processes” in their plant and attack them accordingly. The issue here is, what type of plant do they have? Make to Order, Engineer to Order, Make to Stock, Product Line, etc. So you just don’t copy the TPS from someone else’s plant. You do oberservations and then proceed.

Getting back to my original statement here, Lean has not been such a huge success here in the U S because everyone tries to reinvent it! One of my colleagues goes to a Lean convention is California each year and from what he has gathered from talk at this convention, Lean will finally be defined in several years and a standard developed to take out all of the variations that we hear about these days. 6S 5S 39S etc. This must be finally defined.

Another thought here on Lean. It starts first at the Organizational Level. The ownership starts with leadership and they are the sponsors as well as the champions. The toolbox with Value Stream, 5S, Gemba, Kaizen, etc. are just that tools! The culture and organization needs to shift their paradigms and think about the execution of Lean, ownership, empowerment, self directed, and most importantly continuous improvement. The book, “Hitchhiker’s Guide To Lean” states, people need leadership not management. Management just manages the current state. Leadership visions a change to the current state towards the Ideal state via a futrue state map. Management needs to first appreciate and practice Lean personally first. Once they have a deeper understanding, they too will have had their paradigms shifted and thus be able to lead by example. Just stating we are going to do a 5S event, Gemba Walk and others, does not mean they are Lean. Lean starts within ones self, then teamwork-organization! The moral here is that it is the Soft Skills that need to taught before the Operational ones, the toolbox.

Dennis Goldensohn

My Lean perspective.

None but only the CEO need to know anything about Lean in a manufacturing industry where the inputs are materials that need to pass through processes to make an output of products demanded by customers.

This is what the CEO simply has to do.

The CEO must be extremely competent and an expert in Lean Basics. It’s like; you must know letters A to Z with absolute competence and confidence to be able to make words in the first place

The CEO must know LEAN IS ABOUT MANAGING THE COST OF DOING BUSINESS AND REDUCING IT ENDLESSLY. You don’t have to spend senseless amount of time and resources to know lean, except its basic underlying principles to actually get into an action mode on lean in just 1 minute.

The basic underlying lean principle in manufacturing is UNINTERRUPTED VALUE ADDITION AND ACCELERATING IT STEP BY STEP ENDLESSLY in production processes where the input is materials going through processes resulting in the product the customer wants and at the time it’s required by the customer.

Any company which organizes it’s information, human and material resources to achieve the UNINTERRUPTED VALUE ADDITION state has a perfect score of 10 in Lean and it’s fully benefited by it.

Having armed with this basic 1 minute knowledge of lean the CEO simply articulates it to his team, and challenges it to achieve the uninterrupted value addition state in manufacturing processes.

The rest should follow like magic without any body raking their brains like many lean ” expert’s” spending their entire lifetime trying hard through LEAN TOOLS but still achieving nothing.

The CEO lean team comes to know without having to know previously all the “WASTES” INTERRUPTING VALUE ADDITION and without having to undergo confusing teaching and training by the so called ” LEAN EXPERTS”.

The team creates its own rules with the initial struggles to make sense of the Lean vision of their CEO to achieve uninterrupted value addition.

Now the CEO’s Lean team has become intelligent enough to formulate its own rules for Lean after having struggled to figure out how to achieve a state of uninterrupted Value addition. They are now armed with their own articulated “Lean Doctrine”

This is the Lean Doctrine through a statement of damn just TWO simple rules

RULE No 1: Man can wait machine can wait but material shouldn’t wait

As the team practically applies the rule in the Gemba it has no difficulty in figuring out that WIP inventory in between work stations interrupts value addition. Then by logic arrives at a sane conclusion that SINGLE PIECE FLOW processing doesn’t interrupt value addition and that machines have to be grouped close together in the same way as process flows to achieve uninterrupted value addition. That’s cellular flow manufacturing.

Time spent on machine setup hinders value addition. So the team figures out how to not get rid of it totally but to drastically reduce it. In fact they are forced to figure out everything that interrupts value addition without having to know about it before like organized works place with 3s of the 5s the 7 wastes equipment maintenance interruptions(TPM),Equipment production effectiveness(OEE), lack of knowledge and training etc.

Here the team will also figure out that there is some waiting of men and machines but not materials, but still productivity is much higher than before,despite varying processing times (Unbalanced).

There is also a quick realization that pushing for maximum machine and men utilization is extremely counter productive and harmful to the company. It ruins the financial health of the company through senseless investment in WIP with borrowed capital at high interest rates just to keep men and machines busy, that cannot be converted into cash when needed

There is also a quick realization that materials flow like water in a continuous Value stream more like an ant line and Baton of a relay race than a huge clutch of sheep (WIP) hindering smooth materials throughput to block continuity in value addition.

The new materials movement across the shop is also in the likeness of flight of an aircraft as it doesn’t touch the ground until the products are ready to be shipped to customer.

The team also realizes every product doesn’t follow the rule in the ideal form. There are exception like an intermediate subcontracting operation, Heat treatment, plating, phosphating operation etc when Value addition is interrupted albeit temporarily

RULE No 2 Neither man nor machine or material shall wait

As the team experiences higher productivity and gains experience under lean Rule No 1, it also quickly learns how not to make men and machine wait by re engineering processes and setups to make process times as nearly equal as possible.

The key is to make fast operation slow and slow operations fast to De-Bottleneck slow operations by a parallel operation of the slowest process on multiple machines at the same time.

The team also faces issues with shared resources in material flows when materials flowing from different product families run up to the shared resource and wait to interrupt value addition.

When this state is achieved we have the fastest and uninterrupted value addition, which I call it a state in which a “Maximum Manufacturing Velocity” has been achieved. As this state of value addition stabilizes, the CEO challenges the team to achieve a much more superior state through step by step improvement (KAIZEN) to a state of “Manufacturing Acceleration” from “Manufacturing velocity” as long term Goal.

I think we need define Lean Production from a Scientific and Financial perspective, without any reference to companies, individuals or Japanese words. Here’s my take (can be refined I suppose).

For a given installed capacity and an annual demand profile, a Lean Production System maximises its Throughput, minimises its Work In Progress and Flow Times, whilst consistently delivering on quality and timeliness requirements of the customers, thus maximising the ROIC. This is realised by employing an optimal work design, resource allocation and material management plans, supported by a management system that allows two flex the plans in response to external variables in order to sustain maximum ROIC position.

Lean manufacturing is the pursuit of concurrent improvement in all dimensions of manufacturing performance through actions affecting both the production shop floor and the support structure and involving employees at all levels.