In my first post on Hoshin Kanri I explained the details of making the list for the Hoshin. This now has to be combined with a PDCA (Plan, Do, Check, Act). The rigor of PDCA gives value and life to what would otherwise be a simple action list. Let me show you:

In my first post on Hoshin Kanri I explained the details of making the list for the Hoshin. This now has to be combined with a PDCA (Plan, Do, Check, Act). The rigor of PDCA gives value and life to what would otherwise be a simple action list. Let me show you:

PDCA

PDCA is one of the most important tools in lean (or in any kind of process). I have written a whole series on PDCA, starting with The Key to Lean – Plan, Do, Check, Act! Just to review it briefly, the sequence is as follows:

PDCA is one of the most important tools in lean (or in any kind of process). I have written a whole series on PDCA, starting with The Key to Lean – Plan, Do, Check, Act! Just to review it briefly, the sequence is as follows:

- Plan: Define scope, define target, analyze the situation, understand the problem, develop one or ideally more solutions, select the best one for implementation.

- Do: Implement, define the new standard, train your people in the new standard, ensure the standard is followed.

- Check: Did the implementation actually work? Is the problem fixed? A nice presentation is no proof of a solution!

- Act: If it did not work (good enough), why not? What do you need to do to achieve the targets?

While the Plan and Do parts are easy and commonly done all over the world, the Check and Act are much harder. I sometimes have the feeling that management is often not interested in the actual outcome and is satisfied with a nice presentation.

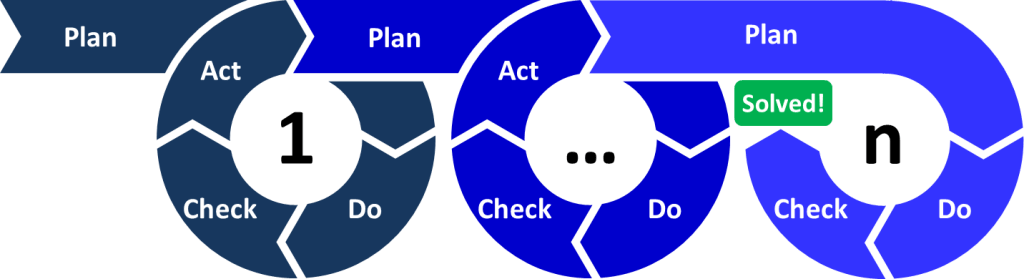

If PDCA is done well, it can develop into a continuing series of PDCA loops until the problem is solved. In this case, PDCA continues with the next problem.

Overlapping PDCA with the To-Do List to Get Hoshin Kanri

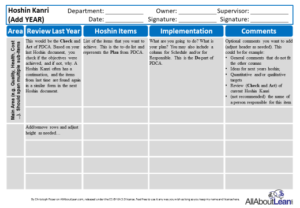

In my previous post we looked at the to-do list that will go into the Hoshin Kanri. On this list are the rows in that document. PDCA represents the columns. The initial to-do list would be the column corresponding to the Plan of PDCA.

In my previous post we looked at the to-do list that will go into the Hoshin Kanri. On this list are the rows in that document. PDCA represents the columns. The initial to-do list would be the column corresponding to the Plan of PDCA.

The columns do not necessarily need to be labeled Plan, Do, Check, and Act. There may be also more than four columns (or less), as long as PDCA is represented. In fact, there is not a standard Hoshin Kanri that is used everywhere, no matter what you hear otherwise. As always in lean, the document has to fit YOUR needs, the solution has to fit YOUR problem. Just copying something from someone else may not help you much.

Below is a selection of possible columns for Hoshin Kanri. These may help as suggestions to see what you may need.

- Review of last Hoshin: This would be the Check and Act of PDCA. Based on your last Hoshin document, you check if the objectives were achieved, and if not, why. A Hoshin Kanri often has a continuation, and the items from last time are found again in a similar form in the next Hoshin document.

- Hoshin Items: List of the items that you want to achieve. This is the to-do list from the last post. Feel free to group it into overarching topics (Quality, Health, Cost …) with a small number of sub-points for each. You may also include a separate column for targets, although not all Hoshins do. They are not necessarily quantitative, but may be qualitative. Together with the Hoshin items, this is the Plan from PDCA.

- Implementation Plan: What are you going to do? What is your plan? You may also include a column for Schedule and/or for Responsible. This is the Do part of PDCA.

- Evaluation: Did it work? Is the problem solved? This column may also be on your next Hoshin; see the top bullet “Review of last Hoshin.”

Some Additional Items

Like any document, you can add a number of additional topics. Not all of them are needed every time you have to decide which ones may be helpful in your case.

Like any document, you can add a number of additional topics. Not all of them are needed every time you have to decide which ones may be helpful in your case.

- Title: Give the document a title, i.e. “Final Assembly Hoshin 2019” or “Personal Hoshin 2015” or similar.

- Date: For which period (which year?) is the Hoshin?

- Owner: Who is in charge of the Hoshin?

- Department: To which department does the Hoshin belong? This should be the department of the owner.

- Supervisor: Who will review the Hoshin with the owner and give feedback?

- Signature Supervisor: A space for the supervisor to sign. This is to show that the Hoshin is completed for this term (year). Please note this does not mean that all problems are solved, however.

- Vision: What are the company (or your) overarching goals or guidelines? What is the corporate philosophy? Ideally, the items on the Hoshin should reflect this vision.

How Many Hoshins?

The power of Hoshin Kanri lies in the focus on the key points. Hence, the number of Hoshin Kanri documents that you are responsive for at the same time should be kept at an absolute minimum, ideally one. You may have a second personal Hoshin besides your corporate one to also improve yourself outside the industry context. Yet, within the industry there should be a maximum of one Hoshin document per person at a time.

The power of Hoshin Kanri lies in the focus on the key points. Hence, the number of Hoshin Kanri documents that you are responsive for at the same time should be kept at an absolute minimum, ideally one. You may have a second personal Hoshin besides your corporate one to also improve yourself outside the industry context. Yet, within the industry there should be a maximum of one Hoshin document per person at a time.

Management must resist the temptation to create different Hoshins for different projects or topics. Similarly, if you are unfortunate enough to have two supervisors who both can tell you what to do, try to avoid having two separate Hoshin documents. If you put everything on your Hoshin that anybody would like to have, then you end up with 40+ different key items, all of which are top priority. Does this sound familiar? If everything is top priority, then nothing is. If nothing is priority, nothing will get done. Again: Limit the number of priority topics that make it on your Hoshin.

What Period Should a Hoshin Cover?

Most Hoshin Kanri documents that I know cover one year. This is usually a good duration, since one year allows for quite a bit of improvement activity. This duration is also long enough to see the results and review the outcome.

Most Hoshin Kanri documents that I know cover one year. This is usually a good duration, since one year allows for quite a bit of improvement activity. This duration is also long enough to see the results and review the outcome.

Again, resist the temptation to do Hoshins more frequently. You won’t get twice as much done if you have two Hoshins per year; you merely increase the organizational overhead, and hence reduce the actual improvement capacity.

Who Should Have a Hoshin?

A personal Hoshin for improving yourself is possible for anyone. A corporate Hoshin is mostly for managers.

A personal Hoshin for improving yourself is possible for anyone. A corporate Hoshin is mostly for managers.

In general, the person having a Hoshin Kanri should be able to influence an area under his control, making not only short-term decisions but also longer-term strategic decisions or changes.

Now you know how a Hoshin Kanri is structured.  I also created a blank PowerPoint Hoshin Kanri Template for you to use. Hopefully it helps you. You can edit the PowerPoint to match the document to your needs.

I also created a blank PowerPoint Hoshin Kanri Template for you to use. Hopefully it helps you. You can edit the PowerPoint to match the document to your needs.

I hope this article was helpful for you. In my next post I will explain how different Hoshin Kanri documents influence each other across the hierarchy. Until then, go out and organize your industry!

P.S.: Many thanks to Isao Yoshino for his input!

PDCA is extremely valuable, and can work on a number of different levels, from a basic ‘let’s think this through before we jump in feet first’, to a much more detailed game plan. However, the steps you detail are different from those I’m familiar with!

I also understand Hoshin to be ‘Policy Deployment’, and ‘Kanri’ to be management, so I’m not clear on how a business can have ‘a policy deployment’. Why not ‘an annual objective plan’?

In terms of PDCA, I understand the P to simply detail the 5ws + 1H of the plan. The only action that might take place is the installation of a temporary countermeasure if PDCA is being used as a problem-solving process. Moving on to D, that would normally encompass clearly understanding the current situation, considering causes, considering alternatives, identifying best alternative and planning trial. In ‘Check’ we’re testing to see if trial is effective, expectations met, no unforeseen side-effects etc. Repeat as necessary until we’ve reached desired state. Only in Action do we set a new standard – including training, monitoring, maintenance etc. Final sub-part of action is to review the PDCA process.

Hi Steve, i wrote more about the actual “deployment” part in my next post (next tuesday). As for the PDCA, there are many (MANY) variants of it, see my post The Many Flavors of the PDCA. Thanks for commenting.

thanks a lot for this sharing!

I like to read through your article though recently I am too busy I skipped some.

This article you reminded me again the key to lean is PDCA!

First of all, I would like to compliment you for your open minded view towards available tooling. That’s always very helpful!

I am not so much familiarized with Hoshin Kanri as I am with the OGSM methodology and would like to understand the differences. Is Hoshin Kanri also multi-layered and therefore connected to actions / goals on higher levels? How would you define your items on the HK ? What would be the role of higher management layers in this? – Perhaps you could answer these questions in another post. I would be very interested. Thanks

Hi Koen, indeed the layered approach will be in my next post. As for OGSM, see my glossary entry for OGSM, I am missing the C&A of the PDCA. Also thanks for the nice words on my writing 🙂

Christoph – Happy that you and Isao Yoshino got to connect on the topic of hoshin kanri and leadership. I’ve learned much from his experiences at Toyota.

A few weeks before you and I met up in Japan, I wrote an article last year with additional examples of Mr. Yoshino’s approach to Hoshin Kanri as applied to personal goal setting, including some photos of Mr. Yoshino’s own hoshin.

https://kbjanderson.com/toyota-leadership-lessons-part-10-practice-personal-hoshin-kanri-or-goal-setting/

Christoph, many thanks for your blogs which I find most interesting. I am also enjoying reading your excellent book Faster, Better, Cheaper.

I was very interested to see your composite PDCA diagram in this blog. I have expressed a lot of views about PDCA. I believe that it is a natural universal learning cycle that we all use personally instinctively to varying degrees of proficiency. However, it does not necessarily happen naturally within a group/organisation and has to be orchestrated via a management system.

PDCA also has the property of being fractal which is what your diagram suggests. Applying PDCA to elaborate P can equally be applied to DC&A as well. PDCA also operates at different cycle rates in levels of management as shown in ‘Order from Chaos’ published in Quality World in April 2011. Refer to https://www.integratedmanagement.info/technical-papers

Hi Christoph, Thanks for making the HK simple enough to understand, and as you rightly said.. Most of the consultants made is tough and complex with formulaes, and fancy titles.

Can you help me understand what is SDP(Strategy Deployment Process), Heard a lot about it.. during college days.. but never came to see it.

Thanks once again.

Hi Harish, sure can. See my next post (coming out today at noon).

Hi Christoph, I think the “implementation plan” part of your PowerPoint template above is better to be a “plan” phase of PDCA cycle, with the items inherited from the last cycle and the list you would undertake in current cycle. In between these and the “evaluation”, would be the actual performance; the “Do” step. Thank you for your insightful posts and regards.

Hi Suleyman, please feel free to adapt the template for your needs. I am always skeptical of rigid formats, and a great fan of adapting tools to whatever fits your situation.