Many companies want to achieve a lean production system. For this, these companies conduct lean transformations. And this in turn needs the buy-in of the people who will be working with the transformed system later on, usually the operators. However, a problem many lean transformations encounter is that … the operators don’t want to transform! This is of course a challenge. Let’s have a look at why this happens, and how you can prevent and overcome the issue.

Many companies want to achieve a lean production system. For this, these companies conduct lean transformations. And this in turn needs the buy-in of the people who will be working with the transformed system later on, usually the operators. However, a problem many lean transformations encounter is that … the operators don’t want to transform! This is of course a challenge. Let’s have a look at why this happens, and how you can prevent and overcome the issue.

Why Do Operators Resist Change in a Lean Transformation?

There are a number of different reasons why operators may resist a lean transformation, or generally any change to their working environment. First of all, people don’t like change. They have adapted to the current situation, and changing this takes a mental effort. If you have the option to change or not, no change is usually the easier one.

This is closely related to the worry that a change project will cause extra work for the operators. Changing your system is a lot of effort, and some of the effort has to come from the operators, most likely the supervisors. Faced with extra work, some operators would rather not change.

A change also causes uncertainty. Of course, management promises that all will be better afterwards, but is it really true? After all, the promise of management does not hold much weight in all companies – sometimes even justifiably so. There are plenty of factories where the employees got burned by a previous Six Sigma or other project that made everything worse. In some factories this has even happened multiple times, and – understandably – operators are hesitant about the next crazy idea raining down from management.

A change also causes uncertainty. Of course, management promises that all will be better afterwards, but is it really true? After all, the promise of management does not hold much weight in all companies – sometimes even justifiably so. There are plenty of factories where the employees got burned by a previous Six Sigma or other project that made everything worse. In some factories this has even happened multiple times, and – understandably – operators are hesitant about the next crazy idea raining down from management.

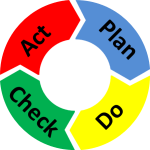

The operators may also have a lack of trust in the skills of the management or the lean transformation in general. Even if the planned change could work, operators may have been disappointed in the past by getting a half-finished system. The overall change was implemented, but nobody stayed around and helped the operators with the fine tuning, the fixing of all the small bugs and kinks, and the effort to make it into a workable system. Or, to use lean language, they did not do the “Check” and “Act” of the PDCA, which for me is the cornerstone of any lean project.

The operators may also have a lack of trust in the skills of the management or the lean transformation in general. Even if the planned change could work, operators may have been disappointed in the past by getting a half-finished system. The overall change was implemented, but nobody stayed around and helped the operators with the fine tuning, the fixing of all the small bugs and kinks, and the effort to make it into a workable system. Or, to use lean language, they did not do the “Check” and “Act” of the PDCA, which for me is the cornerstone of any lean project.

Finally, there is also the possibility that the future state – while being better for the company altogether – may be worse for the individual operators. For example, transforming a job shop into a flow shop is almost always beneficial for the plant. However, for an operator it is much easier to slack off in the chaos of a job shop, and management may have much more control over the workload in a flow shop. Hopefully, not too many operators in your plant want to slack off, but this may be a reason for some (although they probably won’t say it outright).

How NOT to Get Operator Buy-In

Before I go into more detail on how to get the buy-in of the operators, let me first state how NOT to do it. Do not use threats, do not intimidate, and use pressure only in moderation or not at all. Do not do it like Captain Bligh on the Bounty, who supposedly said that “the beatings will continue until morale improves.” Like Captain Bligh, you may have a mutiny on your hands. Also, do not use a death match scenario (the better plant will not be closed)

A newbie manager fresh from university may sometimes think that he is in control. Experienced managers know that it is more of a mutual cooperation. You cannot force workers to do something. Of course they will do it while you are looking, but the moment you turn around they will fall back into their old ways.

Also, your operators are not mindless drones. There are no three-step Jedi mind tricks to turn them into instant followers. Trying any cheap tricks is a serious lack of respect and has a high risk of backfiring. To work with your people, you need to respect your people!

How to Get Operator Buy-In

There are a couple of steps you can take to get the operator to cooperate and support the transformation. As mentioned above, these are not a three-step trick to switch them to your side, but these are actions that can increase your chances of success.

First, explain to them why this transformation is necessary – before you do the transformation. What are the targets? Does it increase quality? Does it reduce cost? How does this relate to the overall goals of the company?

This explanation is not easy. It is not just stating three bullet points, but it should be a serious attempt to convince your people of the need for change. This is usually easier during a crisis, because it will be more obvious to the employees that the company is at risk.

I also helps to work on a problem that is also a problem for the operators. If the workers often have machine problems, or lack of material, it will be much easier to get them on board to solve these problems.

Probably the most important factor is to involve the operators. If the operators contribute to the decision making for the lean transformation, they will have a higher trust that it actually will work (because if you include the workers, chances are much better that it actually will work). Since you usually cannot include everybody on the project team, try to pick a respected operator who has the clout to convince the others. Include the alpha male (or female) in the transformation project team.

If you plan do to many similar transformations (e.g., turn a job shop into multiple flow shops, or to convert the entire value stream into pull, etc.), it may be worthwhile to start with one section. Sell it to the operators as an tryout (which it actually somewhat is) to let them become familiar with the new situation on a small scale before changing the entire plant.

And again, you need to show respect for your people and do the PDCA to have a chance at success. Now, go out, get the people on your side, and organize your industry!

Nice explanation and well thought out. Good tips.

I’ve done this in several plants, and it really works, if you involve the employees and start in one area that isn’t too large.

This is a very informative article and lays out the groundwork that can be lacking in some lean transformation. Although the concepts you have laid out seem like they should be the basis for any lean transformation your incorporation of “How NOT to get Operator Buy-In” is by far the most important because I believe people can get lost in their motives for implementing transformations. When I think about how to get operators to buy into a new lean transformation the first thought I always have is, what are the pain points for the people of the current process. Therefore address problems at their root so that everyone is involved with the new solution. Great tips throughout!

Good summary – I have seen many, many Lean attempts fail for the reasons you mention. I would add another critical factor. Although Lean focuses on operations and flow, it is critical that senior and executive managers are engaged, understand and are committed to changing how they behave. I have seen Lean initiatives fail because senior execs though they could “do Lean” to the business while they continued working the same way with the same behaviour.

Hello Jeremy, yes, you are right. If the people at the top don’t enable it or treat it as unimportant/optional, the project will have a hard time to succeed. As for “unimportant”: It does not matter what the managers say, it matters what they do.