Two more factors for reducing your lead time are the throughput and the lot size. However, the throughput has a smaller effect – although with other benefits that are often larger than the reduction in the lead time. The reduction in the lot size can have a huge effect, although usually only for make-to-stock production. Nevertheless, both are worth looking at if you want to reduce the lead time.

Two more factors for reducing your lead time are the throughput and the lot size. However, the throughput has a smaller effect – although with other benefits that are often larger than the reduction in the lead time. The reduction in the lot size can have a huge effect, although usually only for make-to-stock production. Nevertheless, both are worth looking at if you want to reduce the lead time.

Improve Throughput

Another possible approach to reduce lead time is to speed up the system (i.e., to improve throughput). You simply crank out more parts in the same time.

My apologies, did I say simply? Unfortunately, it is not quite that. If you just randomly improve the speed of your processes, you may waste a lot of effort. The output of a system is defined by the bottleneck. Hence, you need to find the bottleneck. This is complicated by your bottleneck shifting between different processes. I spent a lot of time developing two methods to detect shifting bottlenecks, the Active Period Method and the Bottleneck Walk. Once you found the possible bottlenecks, you need to improve them. While you may think first about technical solutions, there are also organizational solutions to improve bottlenecks. For more details, see my series on bottleneck management. But somehow, you have to improve your throughput.

My apologies, did I say simply? Unfortunately, it is not quite that. If you just randomly improve the speed of your processes, you may waste a lot of effort. The output of a system is defined by the bottleneck. Hence, you need to find the bottleneck. This is complicated by your bottleneck shifting between different processes. I spent a lot of time developing two methods to detect shifting bottlenecks, the Active Period Method and the Bottleneck Walk. Once you found the possible bottlenecks, you need to improve them. While you may think first about technical solutions, there are also organizational solutions to improve bottlenecks. For more details, see my series on bottleneck management. But somehow, you have to improve your throughput.

In practical terms it may be easier to measure this as the line takt, which is the inverse of the throughput. You can also see this as the line cycle time plus the average losses. How long is the average time between the completion of a product? Reducing this will improve your lead time (all other things being equal). If we replace the throughput with the line takt, the lead time equation in Little’s Law changes can be rearranged as shown below.

\[{ Lead Time = Inventory \cdot LineTakt} \]This is now a linear relationship. If you shave one second off your line takt, you will shave one second off your lead time … for every part in the system. Hence, with 1,000 parts in the system, a one-second reduction in the line takt will give you a lead time reduction by 1,000 seconds. The easiest way to see this is as a percentage. Shaving x percent of your line takt will shave the same x percent of your lead time.

Improving throughput feels natural to most people on production. Hence, chances are, the speed of your system has already been looked at many times before. Further improvement potential certainly does exist, but may not always be easy or cheap. It depends on your system if the effort of reducing your line takt is worth the benefit of an improved lead time. Don’t forget that there are also other benefits, like a reduction in production cost through reduced labor and machine invest. In fact, most often when improving throughput, the main goal is to either increase capacity or to reduce cost or both. A smaller side benefit may also be that faster lines may fluctuate a bit less in absolute terms than a slower line, but don’t expect huge benefits from this side benefit. Overall, reducing your line takt (increasing your throughput) will lead to a proportional reduction of the lead time, although this is often less important than other benefits of this change.

Improving throughput feels natural to most people on production. Hence, chances are, the speed of your system has already been looked at many times before. Further improvement potential certainly does exist, but may not always be easy or cheap. It depends on your system if the effort of reducing your line takt is worth the benefit of an improved lead time. Don’t forget that there are also other benefits, like a reduction in production cost through reduced labor and machine invest. In fact, most often when improving throughput, the main goal is to either increase capacity or to reduce cost or both. A smaller side benefit may also be that faster lines may fluctuate a bit less in absolute terms than a slower line, but don’t expect huge benefits from this side benefit. Overall, reducing your line takt (increasing your throughput) will lead to a proportional reduction of the lead time, although this is often less important than other benefits of this change.

Reduce Lot Size (for Make-to-Stock)

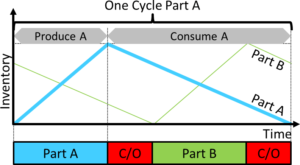

Finally, you can reduce your lead time by reducing your lot size. However, this is most useful for make-to-stock production. In make-to-stock production, the lot size influences the inventory you need to cover the time until the part can be produced again. This is shown below in a simple example with two part types. The inventory over time are the blue and green lines for the respective part types.

If you reduce the changeover time by half, you can reduce the lot size. The new inventory over time is also reduced as shown below. Using Little’s Law, this will also reduce the lead time. Both graphs are examples from a longer post on “What to Do with SMED: Reduce Lot Size or Increase Work Time?”

Hence, for make-to-stock, reducing the lot size can proportionally reduce the inventory and subsequently lead time. The exact numbers depend, among other things, on the number of parts. This massive effect on reducing the inventory is one of the main reason that lean is pushing hard for smaller lot sizes! The reduction in inventory will have significant cost savings. The reduction in lead time, however, usually makes no difference for the customer, since the material is “in stock” anyway. It does, however, make a difference for the speed of information flow within the system too. Quality problems will be detected earlier and fixed easier, product changes will be faster, and overall you will run a much tighter ship. Hence, while the main reason for a reduction in lot size is savings related to inventory reduction, the reduced lead time will also have some benefits, although it will make less difference for the customer.

Unfortunately, this method does not work quite as well for make-to-order. The lot size in make-to-stock provides inventory (stock) to cover the time until the parts are produced again. Since there is no stock to cover with make-to-order, a reduction in lot size will only distribute a larger job over a longer time. It can be done for make-to-order products too, although it does not reduce the average lead time. It does make it easier for the suppliers to provide material as it levels the production a bit more. It also allows you to fit in more urgent jobs between the smaller lot sizes of the formerly larger job. But to significantly reduce the average lead time, you would need to convince your customer to order smaller quantities more frequently, although in this case producing make-to-stock may be better anyway.

Unfortunately, this method does not work quite as well for make-to-order. The lot size in make-to-stock provides inventory (stock) to cover the time until the parts are produced again. Since there is no stock to cover with make-to-order, a reduction in lot size will only distribute a larger job over a longer time. It can be done for make-to-order products too, although it does not reduce the average lead time. It does make it easier for the suppliers to provide material as it levels the production a bit more. It also allows you to fit in more urgent jobs between the smaller lot sizes of the formerly larger job. But to significantly reduce the average lead time, you would need to convince your customer to order smaller quantities more frequently, although in this case producing make-to-stock may be better anyway.

This is the last post of this series looking at the lead time in production systems. Inventory, fluctuations, utilization, throughput, and lot size are the most important levers you can influence if you want to reduce your lead time. The next post will close this small series on the lead time by looking at product development. Until then, stay posted, and go out and organize your industry!

Series Overview

- Reducing Lead Time 1 – Inventory

- Reducing Lead Time 2 – Fluctuations and Utilization

- Reducing Lead Time 3 – Throughput and Lot Size

- Reducing Lead Time 4 – Development

- Suri, Rajan. It’s About Time: The Competitive Advantage of Quick Response Manufacturing. 1 edition. New York: Productivity Press, 2010. ISBN 978-1-4398-0595-4.

- Suri, Rajan. Quick Response Manufacturing: A Companywide Approach to Reducing Lead Times. Portland, Oregon, USA: Taylor & Francis Inc, 1998. ISBN 978-1-56327-201-1.

Thank you for your continued articles. Your last two posts are extremely valuable to organizations and directly affect the production planning process and the cost of manufacturing. Production planning is rarely connected to production and the variation in supplier scheduling and delivery and manufacturing variation to plan is rarely considered in the planning process. I always take companies through the supply chain process to connect production planning to production and shipping. The focus on building to the plan every hour is easy to set up but difficult to follow unless top management understands the benefit and supports the effort. The cost reduction is always significant. There is a value in Production Control Vs. Production Recommendation. The same concept applies to the practice of medicine.

Hi Ronald, I agree. The more production plan understands the production, the better it can plan.

Its worth highlighting how reducing lot size fits into Kingman’s Q=V(U/1-U)T equation……reducing lot size is equivalent to reducing the Variability of parts arrivals at the supply chain’s constraints (eg. processing machines). Similarly, increasing process reliability (eg. preventing process machine beakdowns etc) reduces processing Variability. Hence it can be seen that there are effectively 2 ways to reduce lead-time – reduce variability (aka Lean) or increase capacity (expensive); the former has the added benefit of reducing inventory and enabling a throughput increase without additional capacity (ie.lower cost)

Hi Simon, very good observation with the kingman equation! Small lot sizes in Lean are often and rightfully so considered to be part of leveling.

Christoph,

Again a very interesting article. Regarding MTO and ETO, I have experienced extremely positive impact of one piece flow combined with small batch.

In shop floor it does reduce space by 70% and therefore distances and through snowball effect reduces further the WIP. By producing initially 1 piece of each product variant ordered by the customer, we get a chance to identify documentation and supply issues usually faced on ETO.

Very often the customer cannot install all equipment in one day and has also an advantage to receive a first small batch. It does however requires education of all customer contacts as purchaser, project managers and user have different agenda.

Full benefit is generated when small batch policy is extended to upstream processes as customer order management, engineering and procurement. That’s a challenge.

Hi Patrick, thanks for the good feedback. I didn’t have space on my list of benefits, but it should definitely be there. Thanks for commenting!

Very interesting,

I have a question how can apply lot size reduction in batch processes? I am working in pharmaceutical industry we have issues about WIP between blending process and filling lines because of that our lead time is very high. How can apply little’s law? If you have suggestions pls send me an email.

Hello Rene,

Batch sizes for processing industry is usually one “tank” or whatever the container is to “cook up a batch” (may be slightly different for you, but the idea is the same). In this case it makes often no sense to go lower than the equipment you have. For smaller batches you would need two smaller tanks instead of one big one.

The WIP between blending and filling indicates that blending is faster than filling. Limit the inventory in between (i.e. blending can only start a job if there are no more than 3 batches between blending and filling). This is often a difficult mindset change from the common “Produce! Produce! Produce!…” mindset. Reducing WIP will improve your lead time proportionally.

Hope this helps.

is reducing lead time meaning increasing capacity

Hi Jack, reducing lead time is usually reducing inventory.