Work standards are the backbone of continuous improvement because you need a standard to maintain what you have already achieved. But standards are not easy. A standard should explain everything in sufficient detail without being too detailed…and that is a fine line to walk. The key to the problem, but also to the solution, is the worker who uses the standard. Let me show you.

Work standards are the backbone of continuous improvement because you need a standard to maintain what you have already achieved. But standards are not easy. A standard should explain everything in sufficient detail without being too detailed…and that is a fine line to walk. The key to the problem, but also to the solution, is the worker who uses the standard. Let me show you.

Introduction

I have written an extensive nine-post series on work standards, in addition to the related standard work for organizing the process sequence. The goal of a standard is to clearly describe a task, breaking it down into different steps. It should list all relevant items, and can highlight especially those that are relevant to safety and quality (and, in rare cases, also those that affect cost and delivery time, or in general critical issues). It can include pictures or text, or both. It should also describe all necessary details, but not too many of them…and that is especially challenging. Let me give you an example often used in training people how to write standards.

I have written an extensive nine-post series on work standards, in addition to the related standard work for organizing the process sequence. The goal of a standard is to clearly describe a task, breaking it down into different steps. It should list all relevant items, and can highlight especially those that are relevant to safety and quality (and, in rare cases, also those that affect cost and delivery time, or in general critical issues). It can include pictures or text, or both. It should also describe all necessary details, but not too many of them…and that is especially challenging. Let me give you an example often used in training people how to write standards.

Exact Instructions Challenge: A Peanut Butter and Jelly Sandwich

A peanut butter and jelly sandwich (or in short, PBJ) is a popular snack in the USA (less so in the rest of the world). It consists of two slices of typical American bread, one with peanut butter and one with jelly. Put them together and you have a peanut butter and jelly sandwich. Sounds simple, right? Well, watch the hilarious but educational video below of a dad making a peanut butter and jelly sandwich, following his children’s instructions.

A peanut butter and jelly sandwich (or in short, PBJ) is a popular snack in the USA (less so in the rest of the world). It consists of two slices of typical American bread, one with peanut butter and one with jelly. Put them together and you have a peanut butter and jelly sandwich. Sounds simple, right? Well, watch the hilarious but educational video below of a dad making a peanut butter and jelly sandwich, following his children’s instructions.

It took quite a few tries before the dad could enjoy his sandwich. (If you like this, Josh Darnit and his adorable kids have a whole set of “Exact Instructions Challenge videos” on YouTube. I just wasted a lot of time watching his videos).

Why Was That So Difficult?

Obviously, the kids’ instructions for the dad to make a peanut butter and jelly sandwich needed multiple iterations. That is normal and good. A good standard probably already has some iterations behind its lines. The question is, how detailed do these instructions need to be? If you want to cover every eventuality and possibility to do things wrong, you end up with a book instead of a standard, and nobody is gonna read that. To avoid this, you need two things: train the operator, and have an operator who wants to actually cooperate and do the job.

Obviously, the kids’ instructions for the dad to make a peanut butter and jelly sandwich needed multiple iterations. That is normal and good. A good standard probably already has some iterations behind its lines. The question is, how detailed do these instructions need to be? If you want to cover every eventuality and possibility to do things wrong, you end up with a book instead of a standard, and nobody is gonna read that. To avoid this, you need two things: train the operator, and have an operator who wants to actually cooperate and do the job.

Training

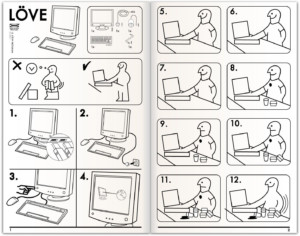

A work standard should not replace training. Whenever possible, train your operators in the use of the standard before letting them roam free to work. There are some rare exceptions—for example, in do-it-yourself types of products. It would not be feasible if IKEA would need to train every customer before they are allowed to assemble their furniture. Instead, the customer only gets the instructions, and that’s it… which of course often leaves the customer puzzled on how to actually assemble it correctly.

A work standard should not replace training. Whenever possible, train your operators in the use of the standard before letting them roam free to work. There are some rare exceptions—for example, in do-it-yourself types of products. It would not be feasible if IKEA would need to train every customer before they are allowed to assemble their furniture. Instead, the customer only gets the instructions, and that’s it… which of course often leaves the customer puzzled on how to actually assemble it correctly.

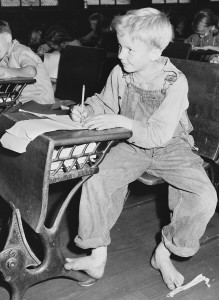

But for any repetitive processes in industry, it is highly advised to train the worker first. You can never write a standard that explains everything and assumes no knowledge. The worker, for example, should be able to read, know what a screw is, and be able to follow instructions. The more the workers know about the process, the less nitpicking a standard needs to be and the more the standard can focus on the key steps. Side note: Some plants in the world (including in the USA) have actually had to create picture-only work standards due to the insufficient literacy of their workers.

But for any repetitive processes in industry, it is highly advised to train the worker first. You can never write a standard that explains everything and assumes no knowledge. The worker, for example, should be able to read, know what a screw is, and be able to follow instructions. The more the workers know about the process, the less nitpicking a standard needs to be and the more the standard can focus on the key steps. Side note: Some plants in the world (including in the USA) have actually had to create picture-only work standards due to the insufficient literacy of their workers.

As a side effect, the more difficult a work process is, both in duration and in complexity, the more you need to train your workers. For example, if you need something welded, you cannot just take anybody and include welding instructions (and welding safety instructions!) in the standard. You need a trained welder. Many assembly lines love to break down the work into a takt time of thirty seconds to two minutes, because that can often be easy to grasp for untrained workers. Longer takt times need higher-skilled workers, or significantly more training. An assembly line for airplanes or machine tools often has a takt of eight hours, with many products differing from each other. For this, you need to train your workers well.

As a side effect, the more difficult a work process is, both in duration and in complexity, the more you need to train your workers. For example, if you need something welded, you cannot just take anybody and include welding instructions (and welding safety instructions!) in the standard. You need a trained welder. Many assembly lines love to break down the work into a takt time of thirty seconds to two minutes, because that can often be easy to grasp for untrained workers. Longer takt times need higher-skilled workers, or significantly more training. An assembly line for airplanes or machine tools often has a takt of eight hours, with many products differing from each other. For this, you need to train your workers well.

In any case, only properly trained workers can follow a standard well. The amount of training correlates to the difficulty (duration and/or complexity) of the task. And, don’t forget to train your workers for different tasks to make them more flexible.

Cooperation

Even with a fully trained worker and a well-written standard, things can go haywire if the worker does not want to cooperate. If one or more workers decide to work-to-rule (also known as Italian strike or nowadays Quiet Quitting), things will quickly go sideways. The worker could do only the minimum required, or he could intentionally misinterpret ambiguous parts in the standard. This results in low productivity and bad quality, and is often considered a lever of industrial action similar to a strike.

Even with a fully trained worker and a well-written standard, things can go haywire if the worker does not want to cooperate. If one or more workers decide to work-to-rule (also known as Italian strike or nowadays Quiet Quitting), things will quickly go sideways. The worker could do only the minimum required, or he could intentionally misinterpret ambiguous parts in the standard. This results in low productivity and bad quality, and is often considered a lever of industrial action similar to a strike.

You may think a better and more detailed standard would resolve this, but I believe this does not work if the motivation for work is lacking. For example, when Frederick Taylor was trying to get his workers to follow his standards and set speeds, the workers forgot almost everything they knew. For shoveling, one worker even forgot how to shovel.

Hence, work standards, and in fact any type of work, requires the good will and cooperation of the workers. This is not a binary on-off situation, but a gradual scale from high motivation, to apathy, to intentional hostility to the workplace. It will also not be the same for all workers, and you probably have both motivated and less motivated people. A large part of industrial success rests on the motivation of your people. How to motivate your people is also a complex topic, ranging from pay and work conditions to actually respecting your people and treating them well. In any case, I hope this was helpful to you. Now, go out and make your standard a success by training and motivating your people, and organize your industry!

Christoph

Continue your educational series. They have a positive effect on how people around the world learn.

My introduction and first real understanding of Standard Work came at Toyota’s Georgetown KY site when President Fujio Cho taught the first class to the management start up team.

Many thanks, Ronald. I will do! (although it is sometimes tough when suffering from writers block. ). keep on reading 🙂

Thx for the nice article Christoph,

Should we not add a third element: Ownership of the standard by the (lead) worker?

The workers should at least be consulted, yet ideally their (thought)leader should own the standard of his team of workers. If you own it, you are driving to continuously improve it after all!

KR, Gerard

Hi Gerard, good point. Someone needs to be the owner of the standard and manage the improvement process. “Anybody” automatically means “Nobody”!

Great observations and insight on work standards. I thought it was interesting to point out the difference between a detailed instruction that will discourage employees and cause them to possibly have an incident that results in downtime or someone possibly getting hurt. I thought it was interesting how you pointed out the “motivated worker”. How would someone motivate a worker who is not motivated to do the job and learn the standards but is a great worker and skilled at that.

Hi Tomhas. The key point here in my view is Respect for people. I wrote a whole bunch of blog posts on this. Hope you find them helpful .

The trend that’s been accelerating here in the USA is what I call de professionalization. service and manufacturing industries are transitioning from being staffed by semi-skilled worker to being staffed by untrained, unskilled, and disposable workforces. the goal is to have an average worker to be as valuable and irreplaceable as an average worker ant in an ant hill. And an IQ to match.

Amazon and a handful of other companies made this work by designing every single process and piece of equipment from the ground up with this goal in mind. But adapting existing processes that were NOT designed for complete idiots is a different story. The plant I used to work at had a lot of accidents when new people were put on jobs with all of five minutes of training and left to their devices.