One of the main hindrances for proper lean manufacturing is, in my view, management by numbers. While few managers actively do management by numbers, a quantitative measurement is still often preferred. The problem is if you can measure the cost but not the benefits of something…which often happens in lean manufacturing. Now let me rant a bit…

One of the main hindrances for proper lean manufacturing is, in my view, management by numbers. While few managers actively do management by numbers, a quantitative measurement is still often preferred. The problem is if you can measure the cost but not the benefits of something…which often happens in lean manufacturing. Now let me rant a bit…

Why Numbers?

Numbers are everywhere in industry. We measure, quantify, calculate, and analyze the data to make decisions. And, in many cases, this is actually good. If you have good data, you can make better decisions. You can set better goals, analyze problems better, understand trends, quantify potentials, and so on. However, there are risks when relying too much on numbers.

Numbers are everywhere in industry. We measure, quantify, calculate, and analyze the data to make decisions. And, in many cases, this is actually good. If you have good data, you can make better decisions. You can set better goals, analyze problems better, understand trends, quantify potentials, and so on. However, there are risks when relying too much on numbers.

The Problem with Numbers: Wrong Numbers

However, there are some problems with an over-reliance on numbers. Numbers can be either wrong, or you don’t have any numbers to begin with.

However, there are some problems with an over-reliance on numbers. Numbers can be either wrong, or you don’t have any numbers to begin with.

Let’s start with wrong numbers. There can be plenty of reasons for that. A simple mistake in an Excel file or a computer system can change the number dramatically. NASA’s $125 million Mars Climate Orbiter broke up and burned in the Martian atmosphere because the supplier software provided a data point in imperial units of pound-seconds2, whereas the main computer expected that number to be in newton seconds2. Instead of circling Mars, the probe impacted the planet. In another example, a Boeing 767 (the Gimli Glider) had to make an emergency landing after all engines failed because the fuel was calculated using a density of pounds per liter instead of kilograms per liter. Luckily, the pilot was an experienced glider pilot and nobody got seriously hurt.

In many other cases, the data on which the numbers are based is inaccurate. You got a number from somewhere, but you don’t know how accurate the number is, or the context it was taken from. For example, I once asked for the cycle time of an injection molding machine. As it turned out, the number I got was just the actual injection and cooling time, not including the opening and closing of the mold. On top of that, the number was two years old, and changed process parameters also changed the speed of the process. I got a number that I asked for, but the number was useless.

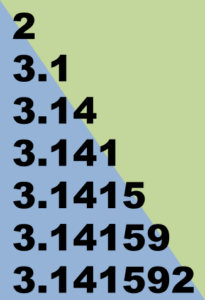

Also often overlooked is the precision of the number. Statisticians will tell you that you need to do numerous measurements, often more than thirty, and then calculate the 95% confidence interval to know how much your number is where it is supposed to be. However, few people in industry do that, and the accuracy of the numbers vary widely.

This is even assuming no ill intent. Unfortunately, number fudging is common in industry to look good. At one major car maker, in order to justify the design of a new car model, they simply assumed that the quality (and hence the quality cost) would be better than any mass-produced car in history, the sales would double annually for five years, and other numerical shenanigans to look good. It worked, the car got built, and people got promoted. But don’t ask about the bottom line…

So overall, inaccurate data, missing context, lack of accuracy, and sometimes even intentional manipulation can turn numbers into questionable guesses or even utter garbage.

The Problem with Numbers: Missing Numbers

A second problem is that for some topics, you cannot get any number at all. This is a problem I often find in lean manufacturing, where it is hard to determine the benefit of a change.

A second problem is that for some topics, you cannot get any number at all. This is a problem I often find in lean manufacturing, where it is hard to determine the benefit of a change.

For example, how do you measure customer satisfaction? While there are some possibilities, it is quite difficult and highly inaccurate. Many companies don’t do that. Even if you have an estimate of the customer satisfaction, how much will this change if you add or remove 10% more customer service agents? How will an additional training of such agents impact customer satisfaction? Nobody knows. Even after the change, it is hard to identify cause and effect. If you axed 10% of your service agents, did that cause the drop in customer satisfaction, or was it the recession, or was it the winter, during which it is dark and cold and everybody is less happy anyway…

Similarly, if you add two mechanics to your maintenance team, will availability go up? Will downtime be shortened? How much? How will this impact overall production? It may be difficult to even wager a guess. Yet, knowing this would be really helpful to make a decision here. In sum, for many decisions there are no critical numbers available at all.

The Cost Accounting Way to Handle Missing Numbers

Conventional cost accounting has a very easy way to handle factors for which they cannot get numbers. If they can’t get a number, then in their numerical world, it simply does not exist. Or, in other words, if they can’t measure it, it must be automatically zero. (Why zero? Because you can add or subtract zeros as much as you want and it makes no difference. Cost accounting does add costs, and a zero has no impact).

Conventional cost accounting has a very easy way to handle factors for which they cannot get numbers. If they can’t get a number, then in their numerical world, it simply does not exist. Or, in other words, if they can’t measure it, it must be automatically zero. (Why zero? Because you can add or subtract zeros as much as you want and it makes no difference. Cost accounting does add costs, and a zero has no impact).

And this is one of the MAJOR problems in lean manufacturing. It is very easy to calculate the cost of an additional maintenance worker or service agent, but it is difficult to impossible to calculate the benefit of a maintenance or service agent. Hence, it is all cost and no benefit, cost will be reduced, and the number of people goes down. Similar examples where the benefit of a change cannot be determined exits all over lean manufacturing, where the cost of an improvement is well known but the benefit is not. This is especially drastic with any kind of support function. Be it customer service agents, maintenance people, supervisors, or anybody else who can help the shop floor, their numbers dwindle because they have a clear cost but a hard to quantify benefit. However, the chaos in manufacturing increases, the frontline worker is overwhelmed with problems but underwhelmed with support, morale goes down, and the entire company goes downhill.

Granted, there are exceptions, and some accountants are fully aware that the model has gaps or even huge gaps. But not every accountant is aware of this, and even fewer report this when asked for a number (understandably, if an accountant can’t provide a number when asked, then this may have negative impacts on his career).

So Why the Reliance on Numbers?

So the question is, why do managers rely so much on numbers? The answer may be multifold. Managing is stressful, and you have to make many decisions with a high level of uncertainty. Numbers give a (perceived) security. Numbers feel good. Especially if they have many digits of precision (regardless if they are true or not).

Additionally, in the stressful world of a manager, a number makes a decision easier. Many managers suffer from decision fatigue, having to make many decisions with high uncertainties. A number gives a (presumed) easy way out telling the manager what to do.

This is also the way many managers learn, no matter if it is from an expensive MBA program or from the culture in the company and their bosses and mentors. You get the numbers, you pick the biggest one. Done.

In some cases, this can even work, at least in the short run. The manager axes the cost or the people (according to the numbers), and cost goes down shortly. The benefit of these people also goes down, but it will take some time for the system to degrade. The manager gets praised as a cost saver, makes a career, and is long gone when the system becomes worse from his decisions. I wrote a whole post series on How to Look Good at the Cost of Your Successor.

Overall, numbers can be really helpful in decision-making. However, you need to be aware of the limits of numbers. They can be wrong, accidentally or intentionally. They can have gaps. They may be inaccurate. Or they may show only one side of the picture, neglecting the other one. Especially in lean, decision-making is still a lot of gut feeling, since a lot of our decisions deal with people, and it is hard to measure the ability and impact of people. Now, go out, decide which numbers to trust and which ones to ignore, and organize your industry!

Interesting read!

Honestly, you’ve just highlighted the number one issue with most Lean implementations and a key reason why so many organizations (outside of Japan) struggle to do it right.

Once you look past the Consultant-Speak aka mumbo-jumbo and the excessive emphasis on KPIs, a lot of Lean really boils down to common sense and good business practices.

Far too many organizations end up calling themselves lean, when they haven’t done much beyond a switch to management by numbers. Bonus idiot points for places who treat every blip in the daily numbers as the beginning of a catastrophe rather than looking at the trend across a week or a month.

You’re spot on about the effect this has on the employees. Everyone quickly figures out what the big wigs “see” vs what’s not even on the radar. A lot of the important intangibles are not measured simply because it’s too difficult to properly measure them. Those tend to go straight out the window when things get busy.

A while back, I’ve read an anecdote from something that happened at the Tesla plant here in Fremont. A small piece of dirt or debris got stuck in a panel press, which caused every part to come out with a dent. When the operators reported the issue to the supervisor, he basically said “screw it, let the rework department down the line deal with it. I’m not eating a downtime hit to my name.”