Twenty-five years ago today, on May 28, 1990, Taiichi Ohno passed away. While he was not the only person behind the Toyota Production System, he was its key driver and is considered the father of the Toyota Production System. To commemorate the anniversary, let’s have a look back at his life, and also at how lean changed after he passed away.

To produce only what is needed, when it is needed and in the amount needed. (Taiichi Ohno)

The Life of Taiichi Ohno

Youth

Taiichi Ohno (大野耐一) was born on February 29, 1912, in Dalian, China during the Japanese control and later occupation of Manchuria. His unusual first name Taiichi comes from the work of his father making fireproof bricks. After returning to Japan, he graduated from Nagoya Technical High School. He received no further formal education beyond his high school diploma.

After graduating in 1932, he started at the Toyoda Spinning & Weaving company, a few years before Toyota Motor was officially founded in 1937. It was during his time at Toyoda Spinning & Weaving that its main competitor, Nichibo, outperformed Toyoda both in quality and in cost. One of the key differences at Nichibo was small lot sizes and integrated manufacturing lines, and it is quite possible that this inspired Ohno later with the Toyota Production System.

The Toyota Production System

In 1943, Ohno moved from Toyoda Spinning & Weaving to the Toyota Motor Company, and three years later he was in charge of a machining workshop. Now Ohno had his first playground to improve. Soon the machines were arranged in sequence of operation, established multi-machine handling, and used small lot sizes.

It was at that workshop that he also started pull production using supermarkets by 1948. Supermarkets were modeled after US retail supermarkets, which Ohno had only heard of when he started the system. Only later in 1956 did he actually visit the US and its supermarkets. To get the information back from the supermarket, they initially just wrote the information on a scrap of paper. This was later formalized, and even later given a proper name: kanban.

Soon Ohno also extended this pull system to his suppliers. Hence Ohno at Toyota pretty much single-handedly established the now-familiar pull system using supermarket and kanban.

From today’s standpoint, this pull system looks so easy and natural. However, in 1950 it wasn’t all that easy. In fact, the “change management” as we would nowadays call it was anything but easy. Ohno faced a lot of resistance. Neither the workers nor the managers liked the new system, which until the early 1960s was known as the Ohno system, or less flattering, the “abominable Ohno system.”

He also incorporated useful methods from other parts of the world, as for example the quality-control approach, developed in the US and brought to Japan by W. Edwards Deming. Toyota also got much inspiration from Ford, as well as the Training within Industry program in the US during World War II, and even from German aircraft manufacturing and their “Takt” time.

Ohno’s Personality

Japanese have a reputation of being polite and quiet. But not Ohno! In order to put his ideas through, he used his entire personality and not always in a positive way. It is said that he was nice to workers, but much less so to managers. He yelled at people, kicked them, and sent them impossible tasks (although this abuse was usually reserved for managers, and he treated ordinary workers rather well).

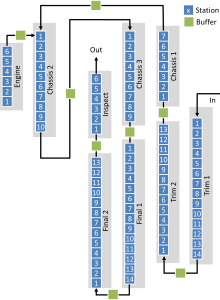

Among other things, he fiercely resisted the adding of any buffer stock in their main assembly lines, which was implemented only after his death (See Evolution of Toyota Assembly Line Layout – A Visit to the Motomachi Plant).

Many of his coworkers were scared of him, and some even had trouble sleeping due to his abuse. Yet to the frustration of some of his colleagues, Ohno’s system outperformed the rest of Toyota. Over time he was given more and more responsibility, and was able to establish his system in more and more areas at Toyota.

Lean in the Western World

Around 1970, the oil crisis hit industry hard worldwide. Sales evaporated, as did profits. Japanese car makers, especially Toyota, fared quite well. A wave of low-priced high-quality Japanese cars hit the US, leading to detailed studies of the Toyota Production System, the most famous one being probably The Machine That Changed the World by Womack and Jones. There was much interest in the “Secrets of Toyota,” and Japanese people with Toyota experience like Shigeo Shingo soon reached cult status in the US.

Ohno also wrote some books about the Toyota Production system (see here for examples). However, if you read these books carefully, you will find little about the details of the Toyota Production System, but rather high-level inspirational content. Even most of the examples are not from Toyota, but from other companies like 7-Eleven.

There even exists a supposed interview where Ohno admits deception (described in the book Profitability with No Boundaries by Pirasteh and Fox). However, I would find it strange that Ohno would admit such a thing, and even stranger that the interview was “in the early 1990s” in Chicago, even though Ohno died on May 28 1990 in Japan at the age of 78. Some things don’t quite add up here…

In any case, even nowadays the true values of the Toyota Production System are hard to grasp and seem to be entirely absent in many wanna-be lean implementations.

His Later Years

By all accounts, Ohno is one of the key contributors to the continuing success and profitability of Toyota. Yet, in official publications of Toyota, he is barely mentioned and usually listed as one of the many second-row people behind the founding Toyoda family, especially Sakichi and Kiichiro Toyoda.

Also, career-wise, he should have become a president and a chairman at Toyota. However, he never made it beyond vice president when he left Toyota in 1978. He afterward became chairman of one of the other companies in the Toyota group, Toyoda Gosei. In view of his achievements, this is definitely an affront against Ohno.

As for the reason for this slight, there are two theories. First, it is said that while Ohno muddled the information about the Toyota Production System, he did speak about it, and hence released confidential information. However, another theory, which sounds more plausible to me, is that through his forceful personality, he made too many enemies who eventually blocked his career advance.

Taiichi Ohno died twenty-five years ago today on May 28, 1990, in Toyota City at the age of seventy-eight from heart failure.

His Legacy

Due to his forceful personality and his high standing within Toyota, he had a major influence on Toyota. Without him, I doubt that Toyota would have been anywhere near as successful, and may not have become the largest car manufacturer in the world. His ideas and visions still hold true for modern manufacturing. Creating a pull system and establishing flow is still one of the keys for an efficient production. He is rightfully considered by many to be the father of the Toyota Production System.

PS: If you would like to read more about history of manufacturing, then check out my book:

PS: If you would like to read more about history of manufacturing, then check out my book:

Roser, Christoph, 2016. “Faster, Better, Cheaper” in the History of Manufacturing: From the Stone Age to Lean Manufacturing and Beyond, 439 pages, 1st ed. Productivity Press.