One successful approach to leveling is one-piece flow leveling (also known as single-piece flow or continuous flow). Last week I described the theory. This week I talk about implementation, and its combination with capacity leveling. I also look at what else there is in leveling.

One successful approach to leveling is one-piece flow leveling (also known as single-piece flow or continuous flow). Last week I described the theory. This week I talk about implementation, and its combination with capacity leveling. I also look at what else there is in leveling.

It is not EPEI with a Daily Cycle

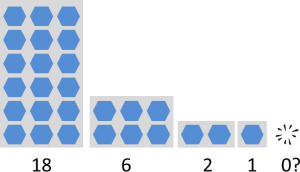

As described in earlier posts, EPEI leveling depends on a repeated fixed pattern, but it does not work. One piece flow leveling has no larger repeating pattern. Instead, you try to make your lot sizes a s small as possible and well mixed within the time-frame that you plan your production. You do not aim to produce every part, only the parts you need within that time frame.

Assuming you have a change over time of zero and are able to do one piece flow. If you create a production plan every day for the fourth day in the future, then you should mix this production for the fourth day as much as possible as described in the last post.

If you are close to one piece flow, but not yet there, one piece flow leveling is still possible. Assume your minimum lot size is 100, and you can produce 10.000 pieces per day. You still can mix up to 100 different lots or part types within one day.

If your minimum lot size is more than half a day or so, mixing within a daily planning cycle for one piece flow leveling becomes difficult or impossible. Having a longer planning cycles may sound like a possibility (e.g. you always plan a complete week, and mix within this week). However, the longer the planning cycle, the more likely that something will change. Hence, with larger change over times and hence larger lot sizes, this one piece flow leveling may not be possible. In this case you should focus on reducing change over times (see below). However, you still can do capacity leveling.

The Practical Implementation of One-Piece Flow

In sum, one-piece flow leveling is to have a lot size of one and to mix up the sequence as much as possible. This will smoothen your production and give you many of the positive effects of leveling. This is all very nice in theory, but hard work in practice.

How to Get There – Make Lot Sizes Smaller

Not every manufacturing system can jump to lot size one as soon as it wants to. Often, there are quite some technical difficulties to overcome. Sometimes more challenging are also the mental difficulties of the workers and managers to move away from the “Large lot size is good” thinking. In sum, you probably cannot change everything directly to lot size one.

Rather, do it in steps. Lean is all about doing many small steps. Try to reduce the lot size in only one part of the plant to only as low as you dare. Of course, you should pick the area with the highest chances of success, otherwise you risk that leveling is seen as a failure and waste of time. Or worse, your work and effort is seen as unhelpful on the shop floor.

The Tool for Lot Size Reduction – SMED

One key aspect of reaching one-piece flow is to reduce changeover times, ideally to zero. If you know even a little bit of lean, you have heard of single minute exchange of die (SMED), or quick changeover. That is the right approach here. Work on reducing your changeover times so you can have smaller lot sizes. I have written about SMED before, so I won’t go into detail here.

When “Lot Size One” May Actually Be Too Small

In theory it is easy to talk about lot size one. In practice, however, there are examples where one may be too small. The lean approach was developed in the automotive industry, and for cars a lot size of one is definitely worth the effort.

But what if you produce screws? Or pens? Or bricks? Purists would say that in this case, too, lot size one is the ultimate goal. As a practitioner, I see it more as a relation between cost and benefit. Getting the screws down to lot size one is possible. However, I am not sure if the benefit is worth the effort. Even if you talk about a box of screws, it may be too little.

Calculating the cost of a lot-size-one screw production is already difficult. But estimating the benefit is even more difficult. Hence, doing a solid business case may not be possible here. My gut feeling tells me that a lot size one for screws may not be worth the effort. I would rather put the effort in getting smaller lots of raw materials (e.g., metal bars for screws) more often before going too deep into lot size one at the final production step.

What is the right lot size? For your plant, you must decide. But be wary that the effect of leveling is often underestimated. Often, an even smaller lot size than what you can imagine may still be worth the effort.

How Long It Will Take to Change Your Organization

Hence, start small but do it right. If you now estimate how long it will take to make the entire plant lean, you will probably end up with multiple years. And this does not even include the suppliers. That is correct. It took Toyota thirty years to develop and implement their production system, and they are still working on it. They also started somewhere and did not do everything at once.

However, if your bosses want to turn the entire corporation into a lean system within six months … well … you may have a problem with unrealistic expectations. In this case, I can comfort you that this happens way too often, although this does not help you much. Sometimes an analysis of the prerequisites and conditions may convince management to give you more time, but unfortunately people do not become top management by falling over at every opposition.

Is There More in Leveling?

One-Piece Flow and WIP

In this post I’ve talked about one-piece flow as a tool for leveling. One-piece flow is also often used as an approach to reduce work in progress (WIP). The idea is that one-piece flow has not only lot size one but also no WIP between the stations. This is also a valid direction, although having absolutely no buffer between processes may not be a good cost-benefit for everyone. Just be aware that you need very stable processes, otherwise your overall output will go down drastically (see The FiFo Calculator).

Often, one-piece flow without WIP between stations is described explicitly for manual work, sometimes mixing up different concepts like Chaku-Chaku and U-lines. Manual work can be more stable than machine operations. Manual work can also catch up by increasing speed temporarily. Hence this no-WIP approach has benefits for manual work. Nevertheless, one-piece flow is also possible for machines. In any case, zero WIP it is not strictly necessary for leveling, and may even complicate things if you do it at the same time (small steps, remember?).

Combine One-Piece Flow Leveling with Capacity Leveling

One-piece flow leveling can be combined very well with Capacity Leveling , giving you the benefit of an even smoother system. In fact, these two approaches go together very well. However, please keep in mind that capacity leveling can be done almost always. One piece flow leveling on the other hand requires the ability to change over multiple times per day, which not all systems can do (yet).

A (questionable?) Theoretical Outlook

In literature, there is often a sequence of five different leveling steps described that you would have to go through. These often look like this [with my comments in brackets].

- Fixed sequence, fixed volume [the classic fixed repeating pattern EPEI, often with a one month pattern]

- Faster fixed sequence, fixed volume [ditto, with a two-week or one-week pattern]

- Fixed sequence, unfixed volume [not quite sure what that is]

- Unfixed sequence, fixed volume [probably close to one-piece flow and capacity leveling]

- Unfixed sequence, unfixed volume [supposedly “true north” that not even Toyota has reached yet]

However, whenever I see these, I always get the feeling that something is not right. It especially irks me that 3 is just the opposite of 4, 2 to 5 alternate fixed and unfixed volume, and that 5 is whatever whenever. I also have not yet seen 3 and 5 in reality. It looks like some theoretical abstraction lots of people copy without fully understanding. It is also usually explained only very briefly (except for 1, on which there is much detail). If you know more about this, let me know.

Summary

This concludes the seven-post series on leveling. Again, I recommend both capacity leveling and one-piece flow, but warn against EPEI repeating patterns, although I fear my opinion on EPEI may be controversial to some. In any case, I hope this was interesting for you. Now go out and organize your industry!

Overview of Posts in This Series about Leveling

- Why to do Leveling (Heijunka)

- An Introduction to Capacity Leveling

- Theory of Every Part Every Interval (EPEI) Leveling, Also Known as Heijunka

- The Folly of EPEI Leveling in Practice – Part 1

- The Folly of EPEI Leveling in Practice – Part 2

- Introduction to One-Piece Flow Leveling – Part 1 Theory

- Introduction to One-Piece Flow Leveling – Part 2 Implementation

Also, Michel Baudin wrote a post on Theories of Lean and Leveling/Heijunka on his blog with a review of my series on Leveling. Some of his comments helped me to update and improve the above post. Check his post out for further details on Leveling.

1 thought on “Introduction to One-Piece Flow Leveling – Part 2 Implementation”