In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history. However, there is a whole fruit stand of additional versions with some modifications that have popped up: PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of. Let me explain a bit on the different offshoots and alternatives of the PDCA.

In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history. However, there is a whole fruit stand of additional versions with some modifications that have popped up: PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of. Let me explain a bit on the different offshoots and alternatives of the PDCA.

Common Mistakes with the PDCA (and Some History)

In my previous post I explained how the PDCA (Plan, Do, Check, Act) should work. However, while most people know the PDCA in theory, I find that the practical implementation is often lacking. And, quite frankly, I am also sometimes sloppy with the PDCA way more often than I would like to admit. Time for some reflection and observation on what works, and why so often it does not.

Hence, in this post I will show common pitfalls and problems when doing a PDCA. Also, simply because it is one of my pet interests, I will also show a bit of the history of the PDCA and its origins in quality control.

The Key to Lean – Plan, Do, Check, Act!

Plan-Do-Check-Act (or PDCA) is one of the key elements in lean manufacturing, or for that matter in any kind of improvement process. In my view, it is the most basic framework for any kind of change. All other lean tools are only on top of the PDCA.

Plan-Do-Check-Act (or PDCA) is one of the key elements in lean manufacturing, or for that matter in any kind of improvement process. In my view, it is the most basic framework for any kind of change. All other lean tools are only on top of the PDCA.

In my experience, most lean projects in the Western world fail not because they do not have some detailed tool, but because the PDCA is neglected. Of course, (almost) everybody knows what the PDCA is, but there is a huge difference between knowing the theory and doing it correctly. In this post I will explain in more detail how PDCA should work. In my next posts I will show you the common pitfalls of PDCA, its history, and the many, many different variants of the PDCA that are out there.

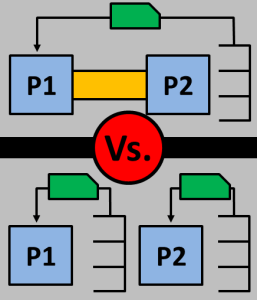

Supermarket vs. FiFo – What Requires Less Inventory?

To create pull production between two processes, you can add either a FiFo lane or a supermarket. In one case you will have the FiFo as part of a bigger kanban or CONWIP loop, and in the other case you split the value stream into two different kanban or CONWIP loops.

To create pull production between two processes, you can add either a FiFo lane or a supermarket. In one case you will have the FiFo as part of a bigger kanban or CONWIP loop, and in the other case you split the value stream into two different kanban or CONWIP loops.

Some questions that I have been pondering are: Which one has less inventory for the same delivery performance? Is it better to use a big loop or two smaller loops for the WIP and delivery performance trade off?

The A3 Report – Part 3: Limitations and Common Mistakes

In the last two posts I showed you the basics of the A3 report and the (possible) content of the A3 report. In this last post of this series, I would like to talk about common mistakes and the limitations of the A3 report. Overall, for me the A3 report is a minor tool to help organize the real work of problem solving, despite all the fuzz some make about the A3 report.

In the last two posts I showed you the basics of the A3 report and the (possible) content of the A3 report. In this last post of this series, I would like to talk about common mistakes and the limitations of the A3 report. Overall, for me the A3 report is a minor tool to help organize the real work of problem solving, despite all the fuzz some make about the A3 report.

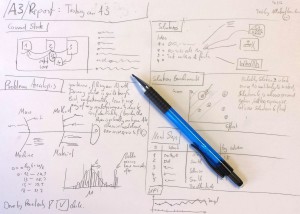

The A3 Report – Part 2: Content

In my last post I wrote about four basic factors for an A3 report (one sheet / A3 size / with pencil / on the shop floor). This week I would like to show you what goes in an A3 report. The important framework here is PDCA (Plan, Do, Check, Act). However, in my view there is no single perfect A3 template that will fit all of your problems. Rather, an A3 is created on the go. Make the tool fit the problem, not the other way round!

The A3 Report – Part 1: Basics

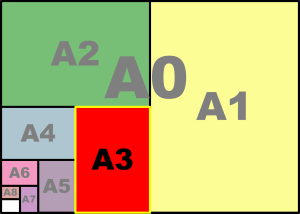

If you know your way around lean, you surely have hear about the A3 report, famously named after the DIN-A3 paper size. It is also known as the A3 problem-solving sheet. The goal is to get all the necessary data on one sheet of A3 paper using pencil while you are on the shop floor. The A3 report is commonly used for problem solving, but also for project management or status reports.

If you know your way around lean, you surely have hear about the A3 report, famously named after the DIN-A3 paper size. It is also known as the A3 problem-solving sheet. The goal is to get all the necessary data on one sheet of A3 paper using pencil while you are on the shop floor. The A3 report is commonly used for problem solving, but also for project management or status reports.

On the Benefits of a Pencil in Lean

In many lean books and other writing, it is often recommended to use a pencil for certain tasks as, for example, the A3 report. Yet, I have seen very few uses of pencil in lean manufacturing in the Western world. Most of the documents are computer printouts based on Excel, PowerPoint, or Word. The few handwritten documents are usually done in pen (see also my post on The Advantage of Handwritten Data on the Shop Floor).

In this post I will look into why almost nobody uses pencils and why it would be good to use more pencils. I myself am also guilty of that, but I plan indeed to use more pencil in the future.