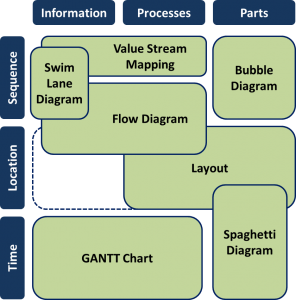

Organizing your manufacturing system is one of the keys to success in manufacturing. There are different tools available, although I have the feeling they are often mashed together or confused. Time for a structured overview of the different manufacturing diagrams available, with recommendations. The following post does not give a full explanation on how these visualizations work. Instead, I want to give you a summary of what is out there, so you can pick the right tool to improve your system.

Organizing your manufacturing system is one of the keys to success in manufacturing. There are different tools available, although I have the feeling they are often mashed together or confused. Time for a structured overview of the different manufacturing diagrams available, with recommendations. The following post does not give a full explanation on how these visualizations work. Instead, I want to give you a summary of what is out there, so you can pick the right tool to improve your system.

230 Years of Interchangeable Parts – A Brief History

Today 230 years ago on July 8, 1785, Honoré Blanc demonstrated the first large scale interchangeability of complex mechanical parts in the courtyard of the Château de Vincennes by disassembling musket locks, mixing the parts, and assembling them again. While it took another 150 years for the idea to take hold firmly in industry, it all started here with 50 muskets. Time for a look back in history.

A Eulogy for Little’s Law

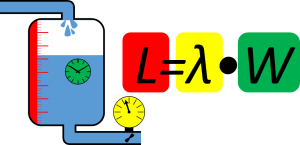

One of the most significant fundamental relations in lean manufacturing is the relation between the inventory, the throughput, and the lead time. The inventory and the throughput are usually easy to measure. The lead time, however, is more difficult. You would need to take the time when a part enters the system and then take the time again when a part leaves the system. Luckily, the lead time can easily and accurately be calculated using Little’s Law, one of the most fundamental laws in lean manufacturing (and also many other places).

One of the most significant fundamental relations in lean manufacturing is the relation between the inventory, the throughput, and the lead time. The inventory and the throughput are usually easy to measure. The lead time, however, is more difficult. You would need to take the time when a part enters the system and then take the time again when a part leaves the system. Luckily, the lead time can easily and accurately be calculated using Little’s Law, one of the most fundamental laws in lean manufacturing (and also many other places).

Theory and Practice of Supermarkets – Part 2

In my last post, I described how supermarkets work in theory. But while knowing the theory helps, actually creating a working supermarket is much more difficult. Are there situations where supermarkets are not so useful? (Hint: Yes!). And what is needed to have a working supermarket? Let’s find out!

Theory and Practice of Supermarkets – Part 1

Kanban, FiFo lanes, and supermarkets are the backbone of many pull system. Some people even define lean production through its use of kanban and supermarkets. Yet why are supermarkets so useful? First we will look at what exactly makes an inventory into an supermarket. My next post will then give tips and hints on the practical use of supermarkets on the shop floor.

Why Pull Is So Great!

One of the most significant insights of the Toyota Production System is its concept of pull production. While often misunderstood, the essence of pull production is a clearly defined limit on the work in progress. Push or pull actually has nothing to do with the direction of the information or material flow. But why does this limit on work in progress make so much difference? Why do pull systems vastly outperform push production systems?

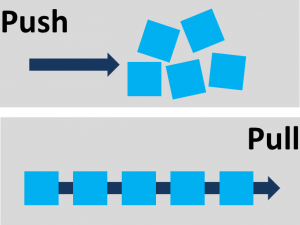

The (True) Difference Between Push and Pull

One of the key differences in lean production is to use pull production rather than push production. While pretty much everyone knows (at least in theory) how to implement it using kanban, the underlying fundamental differences are a bit more fuzzy. But what exactly is the difference between push and pull? Also, what makes pull systems so superior to push systems?

It turns out that most definitions are going in the wrong direction. Even the names “push” and “pull” are actually not well suited to describe the concept. Neither are common illustrations, including the one here in the upper left.

Twenty-five Years after Ohno – A Look Back

Twenty-five years ago today, on May 28, 1990, Taiichi Ohno passed away. While he was not the only person behind the Toyota Production System, he was its key driver and is considered the father of the Toyota Production System. To commemorate the anniversary, let’s have a look back at his life, and also at how lean changed after he passed away.

To produce only what is needed, when it is needed and in the amount needed. (Taiichi Ohno)