In my last few posts I have shown you different ways to establish pull systems, and which one is right for you. This post discusses how you can mix and combine these systems. You can combine some pull systems within the same pull loop, although there are some restrictions. Combinations of different kanban systems are very common, often also including a CONWIP system.

In my last few posts I have shown you different ways to establish pull systems, and which one is right for you. This post discusses how you can mix and combine these systems. You can combine some pull systems within the same pull loop, although there are some restrictions. Combinations of different kanban systems are very common, often also including a CONWIP system.

You can also combine different pull systems for sequential loop, where for example a kanban system feeds into a CONWIP system. This blog post is loosely based on chapter 3.3 and 11.1.7 of my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production.

This is a cross post with the same article on Planet Lean.

What Pull Systems Can Be Combined in the Same Loop?

Sometimes you may need only one type of pull system. In other situations, however, you may want to combine different types of pull systems for different part types in the same loop to fit your needs.

Sometimes you may need only one type of pull system. In other situations, however, you may want to combine different types of pull systems for different part types in the same loop to fit your needs.

Most commonly, you have a combination of make-to-stock products and make-to-order products. This would usually need two different pull systems to achieve a smooth production. The diagram below shows a (again very subjective) compatibility of the different methods with each other within the same loop.

In general, any kanban system is compatible with any other kanban system. You merely change some information on the kanban. A CONWIP system is in its nature like a customizable kanban, and hence also very compatible with kanban. In general, for a combination of make-to-stock and make-to-order, it is recommended to use a mix of kanban and CONWIP.

Reorder systems are mostly used for purchasing, where you don’t really need to worry about compatibility. The way you order one type of goods can be completely independent from the way you order another type of goods. You should worry only that you don’t confuse your people with too many different systems.

It may be possible to combine pull systems with POLCA or Drum-Buffer-Rope. However, the outcome may range from awkward to even more awkward. In general, the fewer different systems you have, the less confusing it will be for your operators. If you use different systems, make sure your first process in the loop has a good standard on which signal takes priority over which other signal, as shown here.

It may be possible to combine pull systems with POLCA or Drum-Buffer-Rope. However, the outcome may range from awkward to even more awkward. In general, the fewer different systems you have, the less confusing it will be for your operators. If you use different systems, make sure your first process in the loop has a good standard on which signal takes priority over which other signal, as shown here.

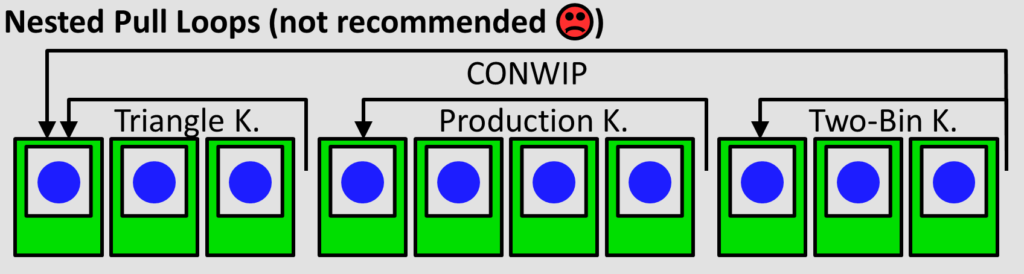

Also, please note that this table applies to the pull system for different part or product types in the same pull loop. Do not use different pull systems for the same part type in the same segment of your value stream. It also does not apply to “overarching” nested pull systems, as shown below. You can find these sometimes in literature, but I seriously doubt the benefit of such nested systems.

What Pull Systems Can Be Combined in Sequential Loops?

It is possible to combine different types of pull production (and sometimes even push if it cannot be helped) for your value stream. One or more kanban loops that feed into supermarkets can easily supply one or more CONWIP loops. Similar can also be done with many other pull methods. An example is shown below.

The table below gives you an overview of the possible combinations. Which type of pull system (or push) can feed into which other type of pull system (or push). There is a lot of compatibility, with only a few restrictions.

First, avoid transitions from make-to-order to make-to-stock. Systems suited for make-to-stock production, like kanban or reorder systems, can easily feed into systems suited to make-to-order production, like CONWIP or POLCA. However, the other direction of make-to-order feeding into make-to-stock is not suitable. If a CONWIP system supplies a kanban system, then you will have custom-made parts supplying make-to-stock products. Since the make-to-order part is only produced if there is a demand, the lead time for the entire system would be excessive. Hence, I advise against such combinations. Fortunately, it is rare to have a make-to-order system feeding into a make-to-stock system, as this usually makes no sense technically.

A second, smaller limitation tries to avoid infrequent large orders for a preceding system that is set up for production of small quantities. In particular, reorder systems may have large orders to refill the entire stock back to the target level, but triangle kanban and two-bin kanban systems can also batch demand into larger orders. Those systems do not convey the information of their demand until they reach the minimum inventory. Once they reach the minimum, they demand everything at the same time. It is possible to have a supply system that produces frequent small quantities for a receiving system that has infrequent but large orders. However, you need additional inventory to decouple these fluctuations. Hence, it may be better to have small orders from the receiving system. Altogether, to avoid large buffer inventories, it may be better to have another kanban system following the first kanban system instead of a reorder system. Yet, if the delta between the minimum level and the target level of the receiving reorder point system is small enough, it can work.

Finally, all combinations involving push are marked neutral, since pull is almost always superior to push. It is possible to have a push-pull combination in both directions if set up carefully. Push-pull boundaries can happen if a transition from push to pull has not yet transformed the entire value stream, or if some segments of your value stream are unsuitable for pull production. Still, go for pull if possible, and see push as a temporary situation until you have time to change it into a pull system. Such combinations along serial loop types can be from push to pull as well as from pull to push.

This concludes my small series on how to select and combine the different possible pull systems. Again, more can be found in my latest book. Now, go out, pick the right pull system, get it working, and organize your industry!

Series Overview

- Pull: A Way Forward for Supply Chains – Guest Post by John Shook

- The Different Ways to Establish Pull Production

- What Are the Criteria to Decide on a Pull System?

- Which Pull System Is Right for You?

- What Different Pull Systems Can Be Combined?

Source

This blog post is summarized from my latest book on pull production, where you will find many more details on all of these systems and how they can work together. You will also find a foreword by John Shook.

Roser, Christoph. All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. 441 pages: AllAboutLean.com Publishing 2021.