On the web and in print, you find frequent mention of a “lean toolbox,” “lean toolbook,” or similar. These books do have their use, and at least one of them is written by an author that I highly respect. Many other lean books also focus on the different tools and methods. But focusing on a set of tools can also be quite misleading. Hence, I wrote this blog post as a word of warning. Every master needs their tools, but the tools do not make a master!

On the web and in print, you find frequent mention of a “lean toolbox,” “lean toolbook,” or similar. These books do have their use, and at least one of them is written by an author that I highly respect. Many other lean books also focus on the different tools and methods. But focusing on a set of tools can also be quite misleading. Hence, I wrote this blog post as a word of warning. Every master needs their tools, but the tools do not make a master!

Standard Tools for Standard Solutions

A “tool box” somehow implies standard tools. For example, a screwdriver. There are standard screwdrivers that will fit standard screws. However, this is quite a simplification. Even among screwdrivers, there are many different types. There is the slot head (ugh, don’t use these). There are Phillips and Pozidriv heads. You probably also have a Torx, and maybe some more like a hex wrench and an Allen key (internal hex) or even more.

Hence, you already have a multitude of different “standard” tools. If you are repairing mobile phones or other electronics, you will have even more. Just for fun, I have assembled a (absolutely not complete) list of screwdrivers below (sorted by the number of positions you can insert the screwdriver into the screw). All of these do exist, are used somewhere, and are (with few exceptions, like the cross and slotted/Phillips) not compatible with each other. In particular the group that is often bunched together as cross-heads or cross-tips look like they are suitable, but they are different standards! If you mix them up, you will damage the screw and the screwdriver and, in the worst case, get stuck with a screw that you can no longer turn.

In terms of lean tools, the number of tools listed is usually fewer than the screwdrivers above. Nevertheless, they also may have a specific purpose. For example, you all know kanban. But kanban only works for make-to-stock items, and not for make-to-order items (in which case CONWIP or POLCA may be better). Even if you have make-to-stock items, Kanban may not be the right tool, and a reorder point system is sometimes preferable. And even if kanban would be the best tool, then there are still different variants of kanban (Triangle, Two Bin, and so on). For more on different ways to pull, check out my book All About Pull Production.

Overall, there is rarely a “standard tool” that fits your problem, since your problem is probably not a “standard problem” to begin with. If all of your problems would be as equal as Torx screws, problem solving would be easy. However, the nature of your problems and their causes are probably quite manifold, and a standard solution rarely fits well. This brings me to my next point:

Adapt Tools for Your Purpose!

A standard tool may not fit, but you may be able to use the idea and adapt it to your specific problem. Let’s take an analogy from industry again. A blacksmith uses a pair of pliers (or thongs) to hold the workpiece. For this, blacksmiths usually have plenty of different pliers. But even then, the smith may in some cases modify the pliers to fit his purpose better. A smith once told me that. ideally, every workpiece should have its custom pair of pliers.

A standard tool may not fit, but you may be able to use the idea and adapt it to your specific problem. Let’s take an analogy from industry again. A blacksmith uses a pair of pliers (or thongs) to hold the workpiece. For this, blacksmiths usually have plenty of different pliers. But even then, the smith may in some cases modify the pliers to fit his purpose better. A smith once told me that. ideally, every workpiece should have its custom pair of pliers.

Or for another example, let’s use injection molding. Injection molding is certainly common in industry, but it still requires a lot of adaptation and customizing to make good-quality and cost-efficient parts. This ranges from the design of the part for molding, the design and building of the mold itself, to the settings for running the injection molding machine, and more. Even if you consider injection molding a standard solution, it is not a fire-and-forget solution, but an a-lot-of-effort-to-make-it-work solution. Both the problem and the solution are just more complex than a screwdriver where you simply need to find the matching screw.

Or for another example, let’s use injection molding. Injection molding is certainly common in industry, but it still requires a lot of adaptation and customizing to make good-quality and cost-efficient parts. This ranges from the design of the part for molding, the design and building of the mold itself, to the settings for running the injection molding machine, and more. Even if you consider injection molding a standard solution, it is not a fire-and-forget solution, but an a-lot-of-effort-to-make-it-work solution. Both the problem and the solution are just more complex than a screwdriver where you simply need to find the matching screw.

The same with lean. Even if you consider some lean tools as standard solutions, you still need to heavily modify and adapt the solution, figure out all the minor problems with it, and put in a lot of effort so the solution fits the problem like a glove, and not a one-size-fits-all hat that never fits. Even if you want to use a normal kanban system, you still have to decide on how many cards, where they go, how to transport them, where to store them, and many more decisions. And that is only for a common implementation. You may even have trickier challenges, like for example the overhaul of an aircraft engine. For a complete overhaul, the engine is taken apart, its parts sent through the material flow, and then put together again. Try to use kanban for that! (Hint: It does not work, as it is usually not a make-to-stock production).

Tools Do Not Make the Master

As I said above, tools can certainly help in your work. But it is not the tool that makes the master! Michelangelo became great not because he bought good chisels! Michelangelo was great because he could use chisels so well (and many other instruments of art and science).

To become great, you need a couple of ingredients. Talent certainly helps. The right environment and support is also necessary. But most of all, it is practice! It is sometimes said that you need 10 000 hours to become an expert, but that claim has no scientific basis. (Side note: By that number I am also an expert on sleeping, eating, and sitting on a chair 😛 ). Regardless, you need to practice to become good at what you do. More is better, and the learning curve never ends (it juts becomes somewhat flatter).

Don’t Forget the Philosophy

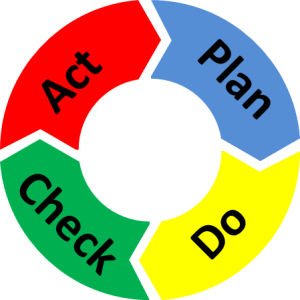

And finally, don’t forget the philosophy behind it. If you mechanically try to copy the movements of a great sculptor, you won’t become great. You need to understand not only the movements to make art, but also the philosophy behind it. Same in lean. Just using the tools is not enough; you need to understand the purpose and the philosophy around it. And – at least for me – this is often the hardest part. In particular for lean, one of the important philosophies is Plan-Do-Check-Act (PDCA), but there are more. One day, when I have really understood lean, I will try to write those philosophies down. But I think I need more practice before that…

And finally, don’t forget the philosophy behind it. If you mechanically try to copy the movements of a great sculptor, you won’t become great. You need to understand not only the movements to make art, but also the philosophy behind it. Same in lean. Just using the tools is not enough; you need to understand the purpose and the philosophy around it. And – at least for me – this is often the hardest part. In particular for lean, one of the important philosophies is Plan-Do-Check-Act (PDCA), but there are more. One day, when I have really understood lean, I will try to write those philosophies down. But I think I need more practice before that…

Now, go out, practice lean by doing it until you become even better than you already are, and organize your industry!

Well done collecting all those different screw heads – about a third were new to me, and the actual names of some of the familiar ones! The most obvious are surely overlooked though – hex heads, male & female. There’s often a tendency to seek the exotic, and when you have an exotic tool need a problem to fit the ‘solution’. If you only have a hammer, maybe every problem looks like a nail?

Thank goodness you never included threads! And yet all of these are someone’s ‘standard’. Whitworth must be spinning in his grave…..

Another point about tools. 50+ years ago when I started work, tradesmen were always wary of having their tools stolen from their toolboxes. I became aware of 7 Statistical Tools a few years later …but then they were called Kaizen Tools …but I found some in a TPM Toolbox a couple of years later. Now they’re leaning. All to do with Marketing, I suppose?!!

Hi Steve, I looked more at internal ones than external ones, otherwise I could also double the list. Also, no claim on completion. Wikipedia has a good list on screw drives with even more drives. As for threads, you can find a picture of my collection of threads here. Yes, I am a nerd!

It’s funny we have recently been having this exact conversation about selecting the right Lean Tools for our implementation. Your points are well-taken and timely!

Many thanks, Allen 🙂

On our initial tour as a class of Vibco shop floor we saw little to no tools in the assembly/machine cell. The tools that were there were 100% what was need for the given cell and nothing else. Our instructor said this is purposefully done. I thought this was great in standardizing each work cell.

Definitely, Justin. The concept is also part of 5S.

Love your side note on the 10,000-hour comment. Made me smile.

As an additional side note, by a rough estimate, I am not yet an expert in using the toilet, but i will become one in the next few decades… 😛