The cost of complexity can significantly impact the bottom line of manufacturing companies. According to A. T. Kearney, the top 30 companies in Germany could earn €30 billion more if they would reduce complexity, increasing their EBIT by three to five percentage points. After discussing the cost of complexity in a previous post, using the Maybach as an example, this post describes the general levers influencing complexity cost.

The cost of complexity can significantly impact the bottom line of manufacturing companies. According to A. T. Kearney, the top 30 companies in Germany could earn €30 billion more if they would reduce complexity, increasing their EBIT by three to five percentage points. After discussing the cost of complexity in a previous post, using the Maybach as an example, this post describes the general levers influencing complexity cost.

Critical Thinking

The Difference Between Lean and Six Sigma

Lean Six Sigma (also abbreviated as 6σ) seems to be everywhere in industry nowadays. There are tons of consultants, job offers, projects, and articles about Lean Six Sigma. In this post, I would like to talk about where Six Sigma comes from, its difference from lean manufacturing, the reason for its popularity, and its shortcomings.

Lean Six Sigma (also abbreviated as 6σ) seems to be everywhere in industry nowadays. There are tons of consultants, job offers, projects, and articles about Lean Six Sigma. In this post, I would like to talk about where Six Sigma comes from, its difference from lean manufacturing, the reason for its popularity, and its shortcomings.

A Lean Obituary for Maybach – A Cautionary Tale About Cost of Complexity

With the end of last year, Daimler stopped selling its flagship vehicle, Maybach. I would like to use this opportunity to talk about the danger and harm to your company by increasing the number of product types sold. As an illustrative (and expensive) example, I would like to split the total cost of the Maybach in its individual parts (as far as I can estimate them). My hope is that this motivates you to reduce, or at least no longer increase, the number of variants in your product portfolio.

On the Lean Guru Shigeo Shingo

Shigeo Shingo is a name that everyone in the United States lean community knows. He is sometimes considered “the world’s leading expert on manufacturing practices and the Toyota Production System,” an “engineering genius,” and the foremost guru of lean production. Some sources even claim he invented the Toyota Production System and taught Taiichi Ohno. Shingo greatly helped to popularize the idea of Lean in the USA. However, he invented much less than what is sometimes claimed, and there is also quite some disagreement in the lean community on this. Let’s have a look at his life and his achievements.

Shigeo Shingo is a name that everyone in the United States lean community knows. He is sometimes considered “the world’s leading expert on manufacturing practices and the Toyota Production System,” an “engineering genius,” and the foremost guru of lean production. Some sources even claim he invented the Toyota Production System and taught Taiichi Ohno. Shingo greatly helped to popularize the idea of Lean in the USA. However, he invented much less than what is sometimes claimed, and there is also quite some disagreement in the lean community on this. Let’s have a look at his life and his achievements.

Lean is Zero Defects? – I don’t think so!

If you work in manufacturing, sooner or later you will find someone who claims that lean manufacturing is all about Zero Defects. Or Zero Inventory. Or Zero Lead Time. Or Zero Whatever. This is bollocks! Zero Defects was a management fad from the 1960s that pops up regularly every now and then again. In this post we will look at what Zeros there really are in lean manufacturing – if any.

If you work in manufacturing, sooner or later you will find someone who claims that lean manufacturing is all about Zero Defects. Or Zero Inventory. Or Zero Lead Time. Or Zero Whatever. This is bollocks! Zero Defects was a management fad from the 1960s that pops up regularly every now and then again. In this post we will look at what Zeros there really are in lean manufacturing – if any.

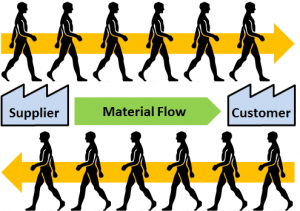

Value Stream Mapping – Why to Start at the Customer Side

Have you ever been to a value stream mapping workshop? If so, you may remember the insistence of the coach to start any mapping activities at the customer side (the end) and then work your way backward (to the beginning). Yet, if you would ask why, you would get only some vague answers about this way being better, more lean, or just the way Toyota does it. In this post I want to go into more detail about whether it may be beneficial for value stream mapping to start at the customer side, and why.

Internal Threat to the Toyota Production System Due to New Hiring Practices

Toyota with its Toyota Production System is the archetype of lean manufacturing, which also makes it to one of the most successful companies on earth. This success is due to outstanding cooperative management at Toyota; however, recent changes in hiring practices threaten the Toyota Production System.

Lean Shop Floor Checklist – Top 4 KPI to Watch in the Factory

Due to popular demand related to my two posts on “Make Your Plant Tour a Success!” and “How to Misguide Your Visitor – or What Not to Pay Attention to During a Plant Visit!,” I have created a checklist for a lean visit to a manufacturing shop floor for you to download. Take this checklist with easy-to-use metrics during your shop floor visit to make yourself independent of potentially misleading data given to you by the shop floor staff. Metrics include worker utilization, machine utilization, inventory reach and turnaround, and order & cleanliness.