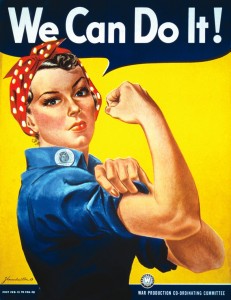

Training within Industry – or TWI for short – was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s, they are still very relevant. In my view, they are pure gold if you have to manage a shop floor. It is to me the best overarching system for training and managing workers, and it significantly influenced Toyota.

Training within Industry – or TWI for short – was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s, they are still very relevant. In my view, they are pure gold if you have to manage a shop floor. It is to me the best overarching system for training and managing workers, and it significantly influenced Toyota.

While technology has changed a lot since 1945, people have not. The methods of TWI still work, and can really help you to improve. Even better, the original US government documents from 1945 are all in public domain. Let me introduce you to TWI. This is the first in a series of five posts on TWI.