Toyota has developed what is probably the finest production system in the world, the Toyota Production System. There is general consensus in the rest of the world that its methods and philosophies can significantly improve efficiency and quality, to the point that anything Toyota does is admired and copied. Some practitioners seem to wear rose-colored glasses when talking about Toyota. However, like any company, Toyota does have its fair share of problems and mishaps to deal with, from the 1950 near collapse, to the US gas pedal recalls during 2009–2011. This post will discuss the employee relationship crisis at Toyota around 1990 and Toyota’s countermeasures.

Toyota has developed what is probably the finest production system in the world, the Toyota Production System. There is general consensus in the rest of the world that its methods and philosophies can significantly improve efficiency and quality, to the point that anything Toyota does is admired and copied. Some practitioners seem to wear rose-colored glasses when talking about Toyota. However, like any company, Toyota does have its fair share of problems and mishaps to deal with, from the 1950 near collapse, to the US gas pedal recalls during 2009–2011. This post will discuss the employee relationship crisis at Toyota around 1990 and Toyota’s countermeasures.

History

The Difference Between Lean and Six Sigma

Lean Six Sigma (also abbreviated as 6σ) seems to be everywhere in industry nowadays. There are tons of consultants, job offers, projects, and articles about Lean Six Sigma. In this post, I would like to talk about where Six Sigma comes from, its difference from lean manufacturing, the reason for its popularity, and its shortcomings.

Lean Six Sigma (also abbreviated as 6σ) seems to be everywhere in industry nowadays. There are tons of consultants, job offers, projects, and articles about Lean Six Sigma. In this post, I would like to talk about where Six Sigma comes from, its difference from lean manufacturing, the reason for its popularity, and its shortcomings.

How a Little Bit of Industrial Espionage Started the Industrial Revolution

The Industrial Revolution changed the lives of ordinary people faster and more radically than any other period in history before it. Within only a few decades, small artisan shops were replaced by large factories. The Industrial Revolution started with the mass processing of cotton. Yet, as we will see, this happened only due to significant industrial espionage across multiple countries.

The Industrial Revolution changed the lives of ordinary people faster and more radically than any other period in history before it. Within only a few decades, small artisan shops were replaced by large factories. The Industrial Revolution started with the mass processing of cotton. Yet, as we will see, this happened only due to significant industrial espionage across multiple countries.

The History of Quick Changeover (SMED)

In the previous post, I explained the basics of a quick changeover. In this post, I will go through the history of quick changeovers (also known as SMED). It is quite interesting to learn how things have developed during the twentieth century. The next post will look at different, unusual ways to teach SMED.

On the Lean Guru Shigeo Shingo

Shigeo Shingo is a name that everyone in the United States lean community knows. He is sometimes considered “the world’s leading expert on manufacturing practices and the Toyota Production System,” an “engineering genius,” and the foremost guru of lean production. Some sources even claim he invented the Toyota Production System and taught Taiichi Ohno. Shingo greatly helped to popularize the idea of Lean in the USA. However, he invented much less than what is sometimes claimed, and there is also quite some disagreement in the lean community on this. Let’s have a look at his life and his achievements.

Shigeo Shingo is a name that everyone in the United States lean community knows. He is sometimes considered “the world’s leading expert on manufacturing practices and the Toyota Production System,” an “engineering genius,” and the foremost guru of lean production. Some sources even claim he invented the Toyota Production System and taught Taiichi Ohno. Shingo greatly helped to popularize the idea of Lean in the USA. However, he invented much less than what is sometimes claimed, and there is also quite some disagreement in the lean community on this. Let’s have a look at his life and his achievements.

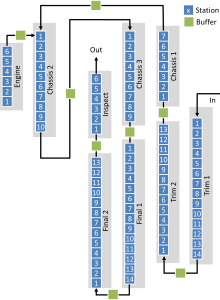

Evolution of Toyota Assembly Line Layout – A Visit to the Motomachi Plant

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Lean is Zero Defects? – I don’t think so!

If you work in manufacturing, sooner or later you will find someone who claims that lean manufacturing is all about Zero Defects. Or Zero Inventory. Or Zero Lead Time. Or Zero Whatever. This is bollocks! Zero Defects was a management fad from the 1960s that pops up regularly every now and then again. In this post we will look at what Zeros there really are in lean manufacturing – if any.

If you work in manufacturing, sooner or later you will find someone who claims that lean manufacturing is all about Zero Defects. Or Zero Inventory. Or Zero Lead Time. Or Zero Whatever. This is bollocks! Zero Defects was a management fad from the 1960s that pops up regularly every now and then again. In this post we will look at what Zeros there really are in lean manufacturing – if any.

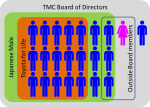

Consistency at Toyota – The Board of Directors of the Toyota Motor Company

The Toyota Motor Company (TMC) is one of the most well-managed firms in the world. Among multinational corporations, it is probably the most famous one. Since its founding in 1937, TMC has continuously improved. The question is, how did Toyota do that? What does Toyota do differently from other companies, who stumble from one problem into the next? I believe the corporate culture and style start with the behavior at the top. Hence, in this post I will look at the board of directors of TMC in more detail.