In manufacturing, a common sentiment is that the line (or generally the process) must run. There is some truth to that, but—counterintuitively—for a system to run well you need to know when to stop it too. This is my second post in a series giving you an overview on when it may be better to stop the line rather than keeping it running (and making everything worse). Keep on reading!

In manufacturing, a common sentiment is that the line (or generally the process) must run. There is some truth to that, but—counterintuitively—for a system to run well you need to know when to stop it too. This is my second post in a series giving you an overview on when it may be better to stop the line rather than keeping it running (and making everything worse). Keep on reading!

Jidoka

Keep Calm and Stop the Line—Part 1

In industry, I often find the view that machines must run. The reasons given for this are that the machines were expensive investments, labor cost will accumulate, and the customer is waiting for products, hence the line must run. There is definitely some truth in this. However, the conclusion that the line must not stop is completely wrong. On the contrary, for the line (or the process in general) to run well, you MUST stop the line in certain circumstances. In this and the next post I would like to look in more detail at when you, rather than pressing forward with production (or rather, your operators), should stop the line. Let me explain.

In industry, I often find the view that machines must run. The reasons given for this are that the machines were expensive investments, labor cost will accumulate, and the customer is waiting for products, hence the line must run. There is definitely some truth in this. However, the conclusion that the line must not stop is completely wrong. On the contrary, for the line (or the process in general) to run well, you MUST stop the line in certain circumstances. In this and the next post I would like to look in more detail at when you, rather than pressing forward with production (or rather, your operators), should stop the line. Let me explain.

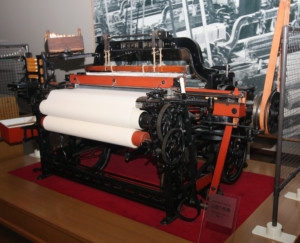

The Toyoda Model G Loom (with Videos)

Toyota Motor originated from the Toyoda loom factory, where Sakichi Toyoda invented looms. Probably the most famous one is the Toyoda Model G Automatic Loom. This loom touches on many points that are part of the Toyota Production System and lean manufacturing. During my last visit to Japan in September, I made some videos detailing many of the features of the Toyoda Automatic Loom from 1924. Be advised: Lots of images and videos ahead!

Toyota Motor originated from the Toyoda loom factory, where Sakichi Toyoda invented looms. Probably the most famous one is the Toyoda Model G Automatic Loom. This loom touches on many points that are part of the Toyota Production System and lean manufacturing. During my last visit to Japan in September, I made some videos detailing many of the features of the Toyoda Automatic Loom from 1924. Be advised: Lots of images and videos ahead!

Examples of Jidoka

In my last two posts I talked a lot about what jidoka is, and the underlying philosophy. Many articles do so. But there are almost no actual examples out there of jidoka. But without examples it is difficult to really understand a concept. A great historic example of this is the Toyoda Model G automatic loom from 1925. This is well known, but here I would like to show you how it connects to jidoka. I will also give you a more modern example of a product that you may even own.

In my last two posts I talked a lot about what jidoka is, and the underlying philosophy. Many articles do so. But there are almost no actual examples out there of jidoka. But without examples it is difficult to really understand a concept. A great historic example of this is the Toyoda Model G automatic loom from 1925. This is well known, but here I would like to show you how it connects to jidoka. I will also give you a more modern example of a product that you may even own.

The Philosophy and Practicality of Jidoka

In my last post I explained what jidoka is (at least in my view). The key part is to stop the line for any irregularity, and resolve the problem. Also try to make sure this irregularity does not happen again. However, this definition is far from universally accepted, and there are many different opinions. Here I will try to show the philosophical idea behind Jidoka as one of the two pillars of the Toyota Production System (the other is JIT).

In my last post I explained what jidoka is (at least in my view). The key part is to stop the line for any irregularity, and resolve the problem. Also try to make sure this irregularity does not happen again. However, this definition is far from universally accepted, and there are many different opinions. Here I will try to show the philosophical idea behind Jidoka as one of the two pillars of the Toyota Production System (the other is JIT).

What Exactly Is Jidoka?

Jidoka is a term commonly used in lean manufacturing, and widely considered one of the pillars of the Toyota Production System, the other being Just in Time (JIT). However, while the word jidoka is often used to impress others, the ideas behind it are much less frequently found outside of Toyota. Maybe this is because so many people interpret jidoka differently. In this first post of a three post series on jidoka, we look at what jidoka actually is.

Jidoka is a term commonly used in lean manufacturing, and widely considered one of the pillars of the Toyota Production System, the other being Just in Time (JIT). However, while the word jidoka is often used to impress others, the ideas behind it are much less frequently found outside of Toyota. Maybe this is because so many people interpret jidoka differently. In this first post of a three post series on jidoka, we look at what jidoka actually is.