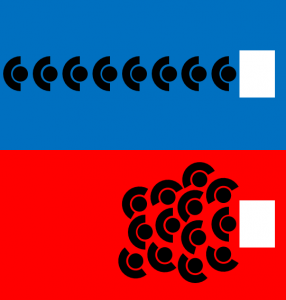

FIFO (first in, first out) is one of the simplest and most basic ideas in manufacturing, and yields significant benefits. It is so simple that I don’t even want to call it a tool, since it is one of the fundamentals in manufacturing (and many other areas). In this post I want to take a closer look at the power of this most fundamental approach to material flow.

FIFO (first in, first out) is one of the simplest and most basic ideas in manufacturing, and yields significant benefits. It is so simple that I don’t even want to call it a tool, since it is one of the fundamentals in manufacturing (and many other areas). In this post I want to take a closer look at the power of this most fundamental approach to material flow.

Lead Time

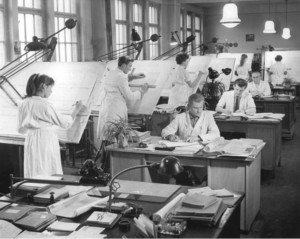

Reducing Lead Time 4 – Development

Reducing lead time is often important for the success of a company. This last out of four posts looks a bit more in detail at the reduction in lead time during product development. This is especially important for make-to-order production, but also for the introduction of new products into the market. Let’s have a look.

Reducing lead time is often important for the success of a company. This last out of four posts looks a bit more in detail at the reduction in lead time during product development. This is especially important for make-to-order production, but also for the introduction of new products into the market. Let’s have a look.

Reducing Lead Time 3 – Throughput and Lot Size

Two more factors for reducing your lead time are the throughput and the lot size. However, the throughput has a smaller effect – although with other benefits that are often larger than the reduction in the lead time. The reduction in the lot size can have a huge effect, although usually only for make-to-stock production. Nevertheless, both are worth looking at if you want to reduce the lead time.

Two more factors for reducing your lead time are the throughput and the lot size. However, the throughput has a smaller effect – although with other benefits that are often larger than the reduction in the lead time. The reduction in the lot size can have a huge effect, although usually only for make-to-stock production. Nevertheless, both are worth looking at if you want to reduce the lead time.

Reducing Lead Time 2 – Fluctuations and Utilization

Reducing Lead Time 1 – Inventory

Lead time is a key factor for customer satisfaction, especially with make-to-order production. Hence, many companies want to reduce this lead time. In this blog post I show you the basic levers that influence your lead time, and a few more that may also apply to some cases. You have to find the combination of these levers that works best for you. This is the first post in a series of four posts on how to reduce lead time. Most of the series focuses on production, but the last post looks into reduction of lead time in development.

Lead time is a key factor for customer satisfaction, especially with make-to-order production. Hence, many companies want to reduce this lead time. In this blog post I show you the basic levers that influence your lead time, and a few more that may also apply to some cases. You have to find the combination of these levers that works best for you. This is the first post in a series of four posts on how to reduce lead time. Most of the series focuses on production, but the last post looks into reduction of lead time in development.