Kanban systems are a huge help in industry, ensuring a steady availability of parts and products without excess stock. However, Kanbans are not necessarily limited to industrial use. In this post I will describe a simple Kanban system for office supplies. This system is also sometimes known as triangle kanban. One benefit of this system is that it will improve the availability of pens, paper, and other supplies. However, a second major benefit is that this provides a risk-free opportunity to train your people in creating and using Kanban systems.

Kanban systems are a huge help in industry, ensuring a steady availability of parts and products without excess stock. However, Kanbans are not necessarily limited to industrial use. In this post I will describe a simple Kanban system for office supplies. This system is also sometimes known as triangle kanban. One benefit of this system is that it will improve the availability of pens, paper, and other supplies. However, a second major benefit is that this provides a risk-free opportunity to train your people in creating and using Kanban systems.

Lean Tools

Ten Rules When to Use a FIFO, When a Supermarket – The Rules

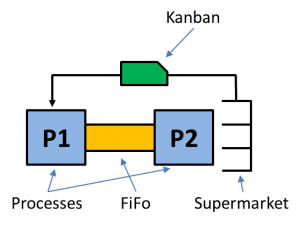

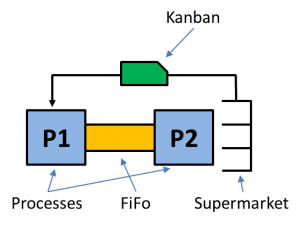

Lean manufacturing pull systems use both FIFO lanes and supermarkets to manage the material and information flow. In my previous post we covered the basics about supermarket and FIFO lanes. Now we go into details about the ten rules when to use a supermarket instead of a FIFO.

Ten Rules When to Use a FIFO, When a Supermarket – Introduction

It is generally accepted knowledge that a lean manufacturing pull system uses both FIFO lanes and supermarkets to manage the material and information flow. However, there are few guidelines on when to use a supermarket and when to use a FIFO lane. This post is the first of a two-part series that will give ten general rules of thumb for when to use a supermarket instead of a FIFO lane. The second post will go into more detail about the ten rules.

Extended Lean Tool Kit for Shop Floor Improvement Projects

Due to the popularity of my lean tool kit, I present you here my extended lean tool kit. These are items and tools that I frequently use for lean manufacturing on the shop floor, but as opposed to the items from the lean tool kit, I bring these along only if I know I will need them.

Due to the popularity of my lean tool kit, I present you here my extended lean tool kit. These are items and tools that I frequently use for lean manufacturing on the shop floor, but as opposed to the items from the lean tool kit, I bring these along only if I know I will need them.

Seven Gadgets for the Basic Lean Toolkit

Lean Shop Floor Checklist – Top 4 KPI to Watch in the Factory

Due to popular demand related to my two posts on “Make Your Plant Tour a Success!” and “How to Misguide Your Visitor – or What Not to Pay Attention to During a Plant Visit!,” I have created a checklist for a lean visit to a manufacturing shop floor for you to download. Take this checklist with easy-to-use metrics during your shop floor visit to make yourself independent of potentially misleading data given to you by the shop floor staff. Metrics include worker utilization, machine utilization, inventory reach and turnaround, and order & cleanliness.

Japanese Multidimensional Problem Solving

In the West, the standard approach for problem solving is to take a good look a the problem, after which a solution approach will pop into someone’s head. This approach is then optimized until the problem is solved. However, while this often ends up with one solution, it usually is far from the best solution possible. In Japan, a very different multidimensional problem-solving approach is common. Rather than just use any solution that solves the problem, they aim for the best solution they can find.

Lean Where You Least Expect It – Toilet Paper Origami

Standardization, visual management, and process confirmation are some important elements of lean manufacturing. Here we have an example many of you are probably familiar with – toilet paper folding at hotels. This simple example can clearly demonstrate the value of Standardization, visual management, and process confirmation.

Standardization, visual management, and process confirmation are some important elements of lean manufacturing. Here we have an example many of you are probably familiar with – toilet paper folding at hotels. This simple example can clearly demonstrate the value of Standardization, visual management, and process confirmation.