Bottleneck detection and management are important in managing or increasing your production capacity. In the first post of this series I talked about fundamentals and improving utilization. The second post looked at the impact of planning on the overall production capacity. This final post in the series will look at the effect of decoupling and the actual process capacity improvement.

Bottleneck detection and management are important in managing or increasing your production capacity. In the first post of this series I talked about fundamentals and improving utilization. The second post looked at the impact of planning on the overall production capacity. This final post in the series will look at the effect of decoupling and the actual process capacity improvement.

Material Flow

Bottleneck Management Part 2 – Improve Bottleneck Planning

Bottleneck detection and management are important when managing or increasing your production capacity. In the first post of this series, I talked about fundamentals and improving utilization. This second post looks at the impact of planning on the overall production capacity. A third post looks at Bottleneck Decoupling and Capacity Improvement.

Bottleneck detection and management are important when managing or increasing your production capacity. In the first post of this series, I talked about fundamentals and improving utilization. This second post looks at the impact of planning on the overall production capacity. A third post looks at Bottleneck Decoupling and Capacity Improvement.

Bottleneck Management Part 1 – Introduction and Utilization

In the past I’ve written a few posts with some nifty methods on how to find the bottleneck (The Bottleneck Walk – Practical Bottleneck and The Active Period Method), and some warnings of which methods don’t work. In this post I would like to go into more detail on what to do once you find the bottleneck! Due to the length of this topic, I have split it into multiple posts. This first post gives an introduction and goes into more detail about increasing utilization. The next post talks about planning. A third post looks at Bottleneck Decoupling and Capacity Improvement.

In the past I’ve written a few posts with some nifty methods on how to find the bottleneck (The Bottleneck Walk – Practical Bottleneck and The Active Period Method), and some warnings of which methods don’t work. In this post I would like to go into more detail on what to do once you find the bottleneck! Due to the length of this topic, I have split it into multiple posts. This first post gives an introduction and goes into more detail about increasing utilization. The next post talks about planning. A third post looks at Bottleneck Decoupling and Capacity Improvement.

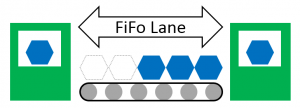

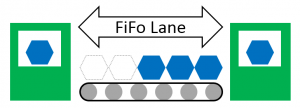

Top Five Cases When NOT to Use a FiFo

Standard wisdom for creating a good material flow is to use FiFo lanes (First in, First out). In other words, the first part that goes into the line should also be the first part that comes back out. As such, FiFo lanes and its big brother, Supermarket, are essential for any lean material flow. However, some rules of wisdom can be bent and others can be broken. Here are the top five cases when NOT to use a FiFo lane.

Standard wisdom for creating a good material flow is to use FiFo lanes (First in, First out). In other words, the first part that goes into the line should also be the first part that comes back out. As such, FiFo lanes and its big brother, Supermarket, are essential for any lean material flow. However, some rules of wisdom can be bent and others can be broken. Here are the top five cases when NOT to use a FiFo lane.

A Successful Example of Lean Implementation – Trumpf and its Synchro Manufacturing System (Part 2)

Half a century ago, Toyota started to develop its Toyota Production System, the archetype of every lean manufacturing system. Almost every manufacturing company nowadays seems to try to implement lean manufacturing. At the same time, most also seem to fail miserably, creating a lot of huff and puff with little benefit. However, occasionally there are (very) few companies that have implemented lean manufacturing successfully. Trumpf and its Synchro production system is such a successful example of Lean manufacturing, and one of the finest production system for machine tool builders. Due to the length I have split this post into two parts. This is the second part.

Half a century ago, Toyota started to develop its Toyota Production System, the archetype of every lean manufacturing system. Almost every manufacturing company nowadays seems to try to implement lean manufacturing. At the same time, most also seem to fail miserably, creating a lot of huff and puff with little benefit. However, occasionally there are (very) few companies that have implemented lean manufacturing successfully. Trumpf and its Synchro production system is such a successful example of Lean manufacturing, and one of the finest production system for machine tool builders. Due to the length I have split this post into two parts. This is the second part.

A Successful Example of Lean Implementation – Trumpf and its Synchro Manufacturing System (Part 1)

Almost a century ago, Toyota started to develop its Toyota Production System, the archetype of every lean manufacturing system. Almost every manufacturing company nowadays seems to try to implement lean manufacturing. At the same time, most also seem to fail miserably, creating a lot of huff and puff with little benefit. However, occasionally there are (very) few companies that have implemented lean manufacturing successfully. Trumpf and its Synchro production system is such a successful example of Lean manufacturing, and one of the finest production system for machine tool builders. Due to the length I have split this post into two parts, the second part being available here.

Almost a century ago, Toyota started to develop its Toyota Production System, the archetype of every lean manufacturing system. Almost every manufacturing company nowadays seems to try to implement lean manufacturing. At the same time, most also seem to fail miserably, creating a lot of huff and puff with little benefit. However, occasionally there are (very) few companies that have implemented lean manufacturing successfully. Trumpf and its Synchro production system is such a successful example of Lean manufacturing, and one of the finest production system for machine tool builders. Due to the length I have split this post into two parts, the second part being available here.

The FiFo Calculator – Determining the Size of your Buffers

In my previous post, I discussed how to Determine the Size of Your FiFo Lane – The FiFo Formula. My preferred method is still an expert estimate. However, if you are interested in the math, here is a small JavaScript calculator that estimates a FiFo size for two processes.

In my previous post, I discussed how to Determine the Size of Your FiFo Lane – The FiFo Formula. My preferred method is still an expert estimate. However, if you are interested in the math, here is a small JavaScript calculator that estimates a FiFo size for two processes.

Determining the Size of Your FiFo Lane – The FiFo Formula

FiFo lanes are an important tool to establish a pull system. They are often combined with kanban. However, while there is a lot of information on how to calculate the number of kanban (the Kanban Formula), there is very little information available on how large a FiFo should be. In my last post I talked about why we need FiFo lanes. In this post I want to discuss how large a FiFo should be.