![]() Pull production using Kanban is one of the major achievements of the Toyota Production System and hence lean manufacturing. The work in progress is limited by the number of Kanban. Overproduction is avoided by producing only if a part is taken out of the supermarket and the Kanban card is returned to the start of production. However, this Kanban system works only if the Kanban returns to the start of production. Losing Kanban means not reproducing goods sold. In this post I would like to talk about different methods to prevent the loss of Kanban, including different Kanban types.

Pull production using Kanban is one of the major achievements of the Toyota Production System and hence lean manufacturing. The work in progress is limited by the number of Kanban. Overproduction is avoided by producing only if a part is taken out of the supermarket and the Kanban card is returned to the start of production. However, this Kanban system works only if the Kanban returns to the start of production. Losing Kanban means not reproducing goods sold. In this post I would like to talk about different methods to prevent the loss of Kanban, including different Kanban types.

Material Flow

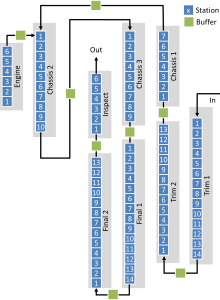

Evolution of Toyota Assembly Line Layout – A Visit to the Motomachi Plant

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Simple Triangle Kanban System for Office Supplies

Kanban systems are a huge help in industry, ensuring a steady availability of parts and products without excess stock. However, Kanbans are not necessarily limited to industrial use. In this post I will describe a simple Kanban system for office supplies. This system is also sometimes known as triangle kanban. One benefit of this system is that it will improve the availability of pens, paper, and other supplies. However, a second major benefit is that this provides a risk-free opportunity to train your people in creating and using Kanban systems.

Kanban systems are a huge help in industry, ensuring a steady availability of parts and products without excess stock. However, Kanbans are not necessarily limited to industrial use. In this post I will describe a simple Kanban system for office supplies. This system is also sometimes known as triangle kanban. One benefit of this system is that it will improve the availability of pens, paper, and other supplies. However, a second major benefit is that this provides a risk-free opportunity to train your people in creating and using Kanban systems.