Sometimes, consultants sell lean as a quick and easy way to success that pays for itself. Unfortunately, this is usually not true, as many companies have found out the hard way. Getting lean in a company is similar to getting a lean body; it is usually neither quick nor easy. Let me show you the different phases of a lean transformation.

Sometimes, consultants sell lean as a quick and easy way to success that pays for itself. Unfortunately, this is usually not true, as many companies have found out the hard way. Getting lean in a company is similar to getting a lean body; it is usually neither quick nor easy. Let me show you the different phases of a lean transformation.

Problem Solving

The Lean Mindset – Te & Kaffi in Iceland

Lean is my life. Whenever I see someone working, I cannot help but to think about the work from a lean point of view. Every now and then I come across a little gem, where I am just thoroughly impressed with someone’s approach to manage and improve their work. During my winter vacation in Iceland, I came across just such a gem with an excellent corporate culture for continuous improvement. Let me introduce Te & Kaffi and its lean mindset.

Lean is my life. Whenever I see someone working, I cannot help but to think about the work from a lean point of view. Every now and then I come across a little gem, where I am just thoroughly impressed with someone’s approach to manage and improve their work. During my winter vacation in Iceland, I came across just such a gem with an excellent corporate culture for continuous improvement. Let me introduce Te & Kaffi and its lean mindset.

Lean Tales in Japan: The Japanese Supermarket Checkout

Japan is a wonderland for anybody interested in lean. Of course there is the archetype of lean manufacturing, the Toyota group and its Toyota Production System. However, access to Toyota plants is restricted, and during their guided tours you can observe only so much. (See for example my post on Evolution of Toyota Assembly Line Layout – A Visit to the Motomachi Plant as the result of such a tour).

Japan is a wonderland for anybody interested in lean. Of course there is the archetype of lean manufacturing, the Toyota group and its Toyota Production System. However, access to Toyota plants is restricted, and during their guided tours you can observe only so much. (See for example my post on Evolution of Toyota Assembly Line Layout – A Visit to the Motomachi Plant as the result of such a tour).

Fortunately, the goal to achieve perfection is also found in many other processes in Japan, many of which you can observe almost anytime, whenever you like and for how long you like. In the past I blogged about Lean in the Japanese Public Toilet and Japanese Standard Pointing and Calling on Japanese trains. This time I’m looking in more detail into the Japanese supermarket, in particular its checkout system.

Dealing with Uncertainty

A lot of decisions in lean manufacturing have uncertainty. How many products will I sell (and what is my customer takt)? Which layout is more efficient? Should I believe expert A or expert B? Uncertainty is a part of life in manufacturing. In fact, the higher up you go in the hierarchy, the more you have to deal with uncertainty. And often these are not just simple “A or B” type of questions, but highly complex and interacting decisions like “What should our new line look like?” Here are some suggestions on how to deal with uncertainty. Please note that they will not answer all of your questions but will help you make better decisions.

A lot of decisions in lean manufacturing have uncertainty. How many products will I sell (and what is my customer takt)? Which layout is more efficient? Should I believe expert A or expert B? Uncertainty is a part of life in manufacturing. In fact, the higher up you go in the hierarchy, the more you have to deal with uncertainty. And often these are not just simple “A or B” type of questions, but highly complex and interacting decisions like “What should our new line look like?” Here are some suggestions on how to deal with uncertainty. Please note that they will not answer all of your questions but will help you make better decisions.

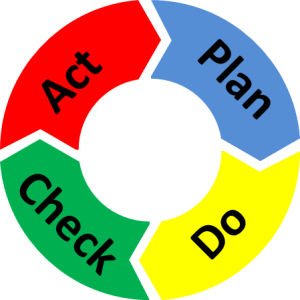

The Many Flavors of the PDCA

In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history. However, there is a whole fruit stand of additional versions with some modifications that have popped up: PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of. Let me explain a bit on the different offshoots and alternatives of the PDCA.

In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history. However, there is a whole fruit stand of additional versions with some modifications that have popped up: PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of. Let me explain a bit on the different offshoots and alternatives of the PDCA.

Common Mistakes with the PDCA (and Some History)

In my previous post I explained how the PDCA (Plan, Do, Check, Act) should work. However, while most people know the PDCA in theory, I find that the practical implementation is often lacking. And, quite frankly, I am also sometimes sloppy with the PDCA way more often than I would like to admit. Time for some reflection and observation on what works, and why so often it does not.

Hence, in this post I will show common pitfalls and problems when doing a PDCA. Also, simply because it is one of my pet interests, I will also show a bit of the history of the PDCA and its origins in quality control.

The Key to Lean – Plan, Do, Check, Act!

Plan-Do-Check-Act (or PDCA) is one of the key elements in lean manufacturing, or for that matter in any kind of improvement process. In my view, it is the most basic framework for any kind of change. All other lean tools are only on top of the PDCA.

Plan-Do-Check-Act (or PDCA) is one of the key elements in lean manufacturing, or for that matter in any kind of improvement process. In my view, it is the most basic framework for any kind of change. All other lean tools are only on top of the PDCA.

In my experience, most lean projects in the Western world fail not because they do not have some detailed tool, but because the PDCA is neglected. Of course, (almost) everybody knows what the PDCA is, but there is a huge difference between knowing the theory and doing it correctly. In this post I will explain in more detail how PDCA should work. In my next posts I will show you the common pitfalls of PDCA, its history, and the many, many different variants of the PDCA that are out there.

The A3 Report – Part 3: Limitations and Common Mistakes

In the last two posts I showed you the basics of the A3 report and the (possible) content of the A3 report. In this last post of this series, I would like to talk about common mistakes and the limitations of the A3 report. Overall, for me the A3 report is a minor tool to help organize the real work of problem solving, despite all the fuzz some make about the A3 report.

In the last two posts I showed you the basics of the A3 report and the (possible) content of the A3 report. In this last post of this series, I would like to talk about common mistakes and the limitations of the A3 report. Overall, for me the A3 report is a minor tool to help organize the real work of problem solving, despite all the fuzz some make about the A3 report.