Flow lines are often the best and most organized approach to establish a value stream. Hence, for flow lines or flow shops you can organize the processes much more easily than for many other types of production systems.

Flow lines are often the best and most organized approach to establish a value stream. Hence, for flow lines or flow shops you can organize the processes much more easily than for many other types of production systems.

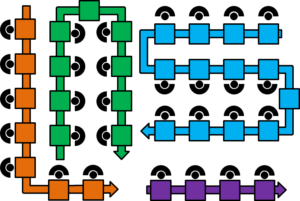

In this series of posts I will look at and compare different ways to pace your production processes. Please note that this is not line balancing about the work content for each process, but rather different options on when to start the work for each process. In the first post I will look at unstructured pacing and pulse lines. In my next post I will go into detail for the continuously moving line.