Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

Introduction

Toyota continuously evolves and changes its production system in a way that is more frequent, more radical, and more successful than its competitors.

They already have the ability of doing lot size one on their production line. The ability to produce multiple car models on the same assembly line in any sequence without set-ups was a radical new idea when it started with Toyota in the 1960s, but nowadays it is industry standard, although some major car makers still prefer batch sizes of more than one (e.g., the Honda Sayama plant).

I have previously written on how Toyota split its assembly line layout into smaller segments and how it changed its shift schedule to make the work easier for its workers. I was quite surprised by how radically they push for lot size one, including aluminum casting in lot size one on demand.

I have previously written on how Toyota split its assembly line layout into smaller segments and how it changed its shift schedule to make the work easier for its workers. I was quite surprised by how radically they push for lot size one, including aluminum casting in lot size one on demand.

Currently they are implementing their Toyota New Global Architecture (TNGA). They realized that they had around one hundred different subplatforms on which to build vehicles, and eight hundred different variants of engines (based on sixteen models, but blooming out into eight hundred variants). Now they are taking major steps to reduce this multitude of products using TNGA.

Their first car based on this TNGA is the 2015 fourth-generation-model Toyota Prius. By 2020, they want to switch half of their models to TNGA. Currently, there are three variants of this platform, GA-L (for “long-mounted engines”) and GA-C and GA-K (both transverse-mounted engines). They work together with Mazda, which is considered to have the best platform approach worldwide with their Skyactiv approach.

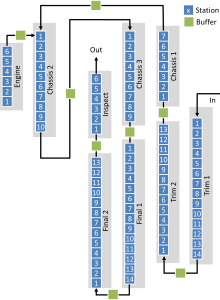

This is all very exciting, but today I want to look at how Toyota is changing its assembly line (again). First of all, it is a bit difficult to find a good name. Toyota calls it a “flexible assembly line” in English (more on that later), but the word flexible is heavily overused nowadays and most people think of flexible assembly lines as mixed-model assembly. But before I go into what Toyota does, let me introduce the idea using easier examples.

Flexibly Configurable Assembly Lines

The basic idea is to have an assembly line that can be moved around, rearranged, and reconfigured on short notice. The idea itself is not new, and I have seen it many times in industry for work cells and chaku-chaku lines. Since the workstations are on wheels, they can simply be unplugged and moved if the product lineup changes, if demand requires an increase or decrease in capacity, or if a new arrangement is simply more efficient. Many of these lines were automotive suppliers. Since car manufacturers like to have a tight grip on their suppliers, sometimes the biggest challenge was to have the customer accept that the line may change without an expensive re-certification of the quality by the customer.

One non-assembly example would be some Japanese supermarket checkouts. As shown below and explained in a previous post, they have one or two workers manning a cashier station. If there is high demand, they have two people for higher throughput; if there is low demand, it is only one. To keep the station at a good size, they have the cashier on wheels.

Flexibly Configurable Automotive Assembly Lines

Now, it’s one thing to roll around a supermarket cash register, but it is a completely different task to do this with an automotive assembly line including all its material flows. Yet, automotive companies in Japan have done it.

Toyota developed what they call a “flexible assembly line” in 2010. However, there is a lot lost in translation from the original Japanese name 伸縮自在な組立ライン (Shinshuku jizai na kumitate rain). The first part means not only “flexible,” but also “elastic; telescoping; expandable; retractable; extensible.” “Expandable” and “extensible” fit the intended meaning much better. It is also part of the TNGA, which not only includes the new platform but also technical improvements and new manufacturing approaches and methods.

Mitsubishi in their Okazaki plant developed a similar concept called Tatami Conveyor (畳コンベア ), where all equipment is also placed on the floor. Even overhead body assembly is done using floor-mounted supports.

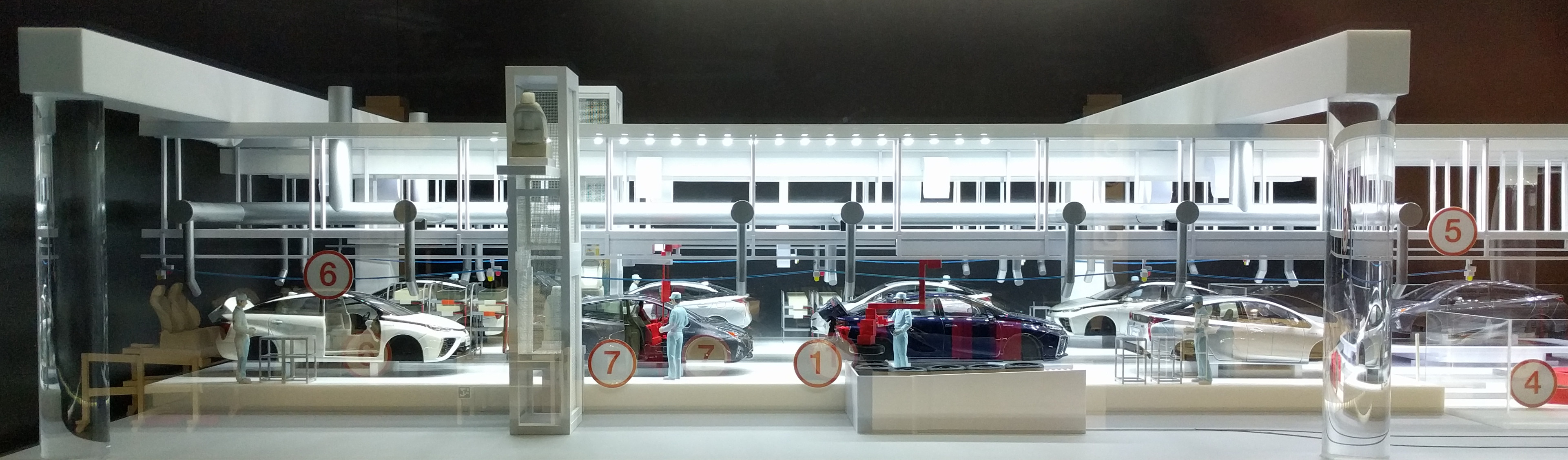

But let’s start with the basics. The image below shows a model from the Toyota Kaikan Exhibition hall, displaying a conventional assembly line. You can clearly see a lot of overhead structure. Not visible but also there are structures in the ground, especially railings, markings for the AGV, and space for turntable gear.

The second picture below shows the new type of line. All of the overhead structures are missing. Also gone are most underground structures. The numbered items are described below the image.

- Collaborative robots working together with humans.

- Tapeless automated guided vehicles. Rather than following markings on the floor, these AGV have a navigation system (not in the picture).

- Solar power is used for some signal lamps and wirelessly connected computers, making the devices easy to move (the number is not visible in this shot, as it is behind the seats on the left).

- Rail-less transport turning equipment. The carts no longer sit on rails but move directly on the floor. Turntables for changing the direction of the car bodies also sit on the floor rather than in an excavated hole.

- Air conditioning towers direct air rather than overhead tubes.

- Call switches (andon lines) are now wireless buttons directly on the carts of the workers.

- All assembly equipment is floor based rather than hanging from overhead. Much of it is on rollers for easy moving.

Toyota already implemented this in its Tsutsumi plant near Nagoya in 2015, and they now want to implement it in all new plants. Below are two still images from a video at the Toyota Kaikan from the Tsutsumi plant. The left shows the assembly line before extension, the right after the extension. The entire change happened over a weekend.

Additional improvements are a much smaller and more energy-efficient paint shop, and a new type of laser welding that is faster than before (laser screw welding). Injection molding machines are able to change tools so quickly that they sit close to the line and produce parts just as they are needed in any sequence, followed by painting in the desired color. Lot size one is used for injection molded bumpers.

Why Do They Do It?

The overarching goal of Toyota is to reduce investment in new lines by 40% to make them “simple and slim.” The resulting plants should also be 25% smaller. There are also a lot of sub-goals.

- Lines can be extended and reduced easier if the demand goes up or down, or if new features are added or removed (i.e., the work content changes). Of course, they still need the empty space to put the line, however. You may also be wondering why they don’t just make a long line and idle some stations if they are not needed. Toyota hates excess inventory, and if these four or so vehicles at these stations are not needed, Toyota would prefer not to have them there. This reduces lead time and also makes for easier communication.

- Overall, the line is easier to change beyond a mere extension. If some stations need to be added in the middle, everything else is just moved a bit.

- It increases reliability. Toyota assembly lines already have a utilization of 95% or more, but occasionally a robot or a machine breaks down. In the old line, this would have stopped the line until the problem is fixed. With the new line, they simply move the robot aside and human workers can take over. While this increases the work, Toyota has such manpower available, and the line keeps running.

- The reduced overhead structure allows a better use of natural light, reducing the electricity consumption.

- Heating, cooling, and general energy consumption is reduced, reducing the carbon footprint too.

- The new lines are cheaper than the old ones.

Does It Work?

Toyota claims that these lines are significantly cheaper than the previous ones. Now, such claims are easy to make. Most improvement projects claim success even though the actual benefit does not always come true. In this case, however, it seems to work.

Tsutsumi in Japan and Georgetown in Kentucky both produce Camrys. Japan has a labor cost very similar to the USA (hourly compensation costs 2012 Japan 35.34 USD, USA 35.67 USD). The South in the USA is about 10% cheaper than the average, which was one of the reasons why Toyota moved there. Overall, labor cost in Kentucky is probably around 10% less than in Japan. A Camry produced in Tsutsumi and shipped to the United States has the disadvantage of the increased labor cost and the shipping cost compared to Georgetown. It should be a no-brainer that Camrys for the US market should be produced in Georgetown.

Tsutsumi in Japan and Georgetown in Kentucky both produce Camrys. Japan has a labor cost very similar to the USA (hourly compensation costs 2012 Japan 35.34 USD, USA 35.67 USD). The South in the USA is about 10% cheaper than the average, which was one of the reasons why Toyota moved there. Overall, labor cost in Kentucky is probably around 10% less than in Japan. A Camry produced in Tsutsumi and shipped to the United States has the disadvantage of the increased labor cost and the shipping cost compared to Georgetown. It should be a no-brainer that Camrys for the US market should be produced in Georgetown.

Not so. Toyota issued an advanced warning to the Georgetown plant that despite their labor and shipping advantage, Tsutsumi can deliver Camrys cheaper to the United States than Georgetown can make them in the United States. Georgetown will have to improve its costs to stay competitive.

In sum, Toyota has changed the game again. This is what probably amazes me the most about Toyota, that they are able to constantly challenge the status quo, question conventional wisdom, and have a good sense of the right direction. I hope you are also able to see such things for your own area of responsibility. Maybe my blog can even help you a bit with this. Now, go out, challenge the status quo, question conventional wisdom, and organize your industry!

Let me suggest another translation for Shinshuku jizai na kumitate rain

What if we call it “clay assembly line” or “Plasticine assembly line”? The word gathers all the properties you described.

Hi Chris,

Perhaps their improvement should be worked and cheaper than 40% to compare with old line as their claim, but there are some points that I’m not clear how they do such as:

1. “All assembly equipment is floor based rather than hanging from overhead” . I understand here you are talking about Final Assembly line, they must be used DC tools for joints, I wonder how they solve the clearance issue with DC line, air line, arm-support to heavy tool.

2. Even they are using automatic movable floor, before wheels will be assemblies, they must use conveyor for car position, is that correct?

3. You know in each of work station, the light must be enough condition for operators. Could you explain more about ” The reduced overhead structure allows a better use of natural light, reducing the electricity consumption” ?

4. In case, a robot or a machine breaks down. They have to stop the line until the problem is fixed, so they have to fill the operators in this process. This is a waste because they have to provide manpower for spare.

Regards.

Tran

Hi Tran,

Toyota may be creating a new ‘simple and slim’ style of factory, but I think it is just an expansion and more aggressive application of the basic principles that have always guided and driven their activities.

To understand this comment we must understand the main goals and activity goals of TPS. The 4R’s. Results, Resources, Resourcefulness and Respect.

The first ‘R’ is for Results. The main performance Results for TPS are to give the customer;

What they want. (The best P, S, and E available in your industry. Product, service and experience). — In the quantity and with the quality – zero defects, they want. (One piece flow with. Jidoka and Poka-Yoke devises will give this capability ). — Delivered when they want it. (Just in time to suit their needs. Takt time is the driver). These values must also be improving faster than those of any existing or future competitor. —

There are three main activity goal areas in TPS to achieve this. Only the first one is used as a central theme in Lean Thinking.

The second ‘R’ is Resources. The goal in this area is to achieve the three performance goals using the minimum ‘Resources’ (i.e. materials – machinery – methods – movement – minutes – manpower – money). Anything above the minimum resources required to produce the product, service and experience that will delight the customer is defined as waste, and is a target for removal. This is one the main areas of focus for TPS and lean activities – Waste elimination. What cannot be removed should then be seen as a target to be continuously improved. The first rule in this area is; ‘can we remove it before you try to improve it. —

(The new Toyota ‘simple & slim’ factory design takes waste elimination to a new level. They will be 25% smaller, cost less to build, use much less energy & reduce emissions. Other features are listed below.) –

The third ‘R’ is Resourcefulness. The goal in this area is to release the ‘Resourcefulness’ (talent, creativity and enthusiasm) of all our people to achieve the first three goals. This ability must also drive the waste elimination and continuous improvement process throughout your organisation and down through your supply chain. The key rule in this area is; ‘sustain the gains, maintain the change.’—

(The new ‘Toyota New Global Architecture’ is a wonderful example of the resourcefulness of their people. It will enable designs to be customised to specifically suit local market needs. 75% of the investment saving from TNGA will be invested into ‘making even better cars’. TNGA will achieve significant reductions in new model introduction times. The new factories can adjust output to suit a 50% change in demand within a single shift. The new smaller style of factory with their no ‘hanging no digging’ features & surface mounted conveyors. To new paint plants that are smaller, 40% cheaper to build and use 40% less energy. Equipment that reduces pre-heat times on sheet metal parts from 5 mins to 15 seconds & now can preheat one piece, to Laser Screw Welding that can halve welding times.) –

The fourth ‘R’ is ‘Respect’. We must see ‘RESPECT’ as the password that gives access to the file that contains our people’s total ability (talent, creativity & enthusiasm). Without the correct password, access will not be possible. We need the ability of all our people to achieve the maximum effectiveness of the first 3R’s. This is one of the key bonding elements between managers & their people. The key rule in this area is; Star managers must make their people shine. –

Anyone who understands TPS will tell you the third and fourth R’s are central to its success. They are missing from too many lean programmes and this is the reason for many of their failures.

When you apply this thinking not only to your external and internal customer contact areas, but also down your supply chain, you will start to understand where and how Toyota’s amazing performance and competitive advantage are created. —

When trying to understand lean and TPS, or anything else, we should always remember Pavlov’s words. “Don’t be a collector of facts. Try to penetrate to the secrets of their occurrence, persistently search for the laws that govern them”.

Hmm, interesting read!

One thing that comes to mind is the fact that Japan’s major challenge is them being a relatively small island nation, and only a fraction of their already limited land being usable. So, expanding outward is not an option. Expanding up is not a real possibility, either, due to earthquakes (Fukushima, anyone?). It’s not unlike computer programmers 30 years ago having to write applications that had to operate within memory and CPU (shared by the OS and other applications on top of that) several orders of magnitude below what’s available in a $300 laptop sold at a Best Buy today.

I don’t know about Europe, but here in US, it’s much cheaper to just take a one-time expense to buy more land, expand the plant (and of course re-optimizing machinery placement) than to upgrade all of the heavy machinery to be rapidly portable on a short notice in a postage stamp sized warehouse. Of course the land in coastal states like CA, FL, or NY is much more expensive. That’s probably why all the big plants are in Midwest.

Finally, being a line operator myself, I wonder what kind of effect a system like that has on the workers (you know…the bees that actually do the value add part). If a plant totally rearranges itself every single day and workers have to constantly adapt to different processes, it sounds like working while standing in quicksand. And if a line is partially staffed, then all bets are off (then again, having to constantly partial staff their lines is one problem that Toyota is lucky enough not to have)…

Cheers,

-Andrey.

Hi Andre, Japan has slightly higher property prices, but I think that is not so much the issue. Earthquakes, too, merely make the buildings a bit more expensive, but Japan has the best earthquake standards in the world. The enormous earthquake in 2011 caused very little structural damage, the tsunami afterwards did. I have visited two plants damaged by earthquakes, Nissan Iwaki (2011 quake) and Honda Kumamoto (2016 quake). they had to stop production, but were up and running again after 3 months. Iwaki still has some odd slopes in the floor where the floor shifted upwards 10 cm or so (blog post with a picture upcoming).

The main benefit of using less space is that you have to walk less! It is more efficient. A british Plant I know had to give up half of its space for a new road, and they were very surprised that afterwards they were 50% more efficient!

Hi Andre

Asia’s culture is difference from Western’s culture, this is the reason why Toyota has much more variant/models then any competitors. They’re invading most of market even their cars is not the best quality.

Asia has a wide variety of cultures, one of which is Japanese. In Japan factories also have a wide variety of cultures, and not every car maker is as good as Toyota (comparative series of blog posts on Japanese automotive plants upcoming). Toyota has successfully exported its culture to its overseas plants (NUMMI being the first famous example, first chapter of my book). GM and VW also have similar or more models, but a worse market segment strategy (See American Automotive Market Strategy of Toyota and Others). Quality wise Toyota has slipped a bit lately, but Taxi drivers in Europe and Japan still usually say that they prefer Toyota due to its reliability, and it is still high in quality ranking reports.

hi Chris,

Could you give us the other look about lean manufacturing in other company? , ex: Ford Motor Company or GM

Sure. Series of blog posts on ALL automotive manufacturers in Japan starting tomorrow. Also, see my two post on the German machine tool maker Trumpf.

Hi Christoph,

Have been following your Grand Tour of the Japanese Automotive Industry… this is good information to know and share. That said, your most recent posting on Mitsubishi’s Okazaki plant its use of the Tatami Conveyor caused me to go back to an early article on the evolution of Toyota’s assembly line in its Tsutsumi plant – where they supposedly make the Prius. Both articles seem to be reinforcing the notion that the entire assembly process is being performed with the car at ground level; that is never being elevated off of and above the conveyor.

Yet, on Toyota’s website there’s a video taken of the Prius assembly line in the Tsutsumi plant which show the car being elevated in order for the axle assemblies and underbody components to be installed. From my POV, this make perfect sense, because attempting to do otherwise seems like it would require some rather fancy maneuvering of both car body and components.

Can you elaborate a bit more on what’s actually happening on a Tatami Conveyor line and how the overall flexibility is being achieved; especially when it comes to the interfaces/interconnects that likely need to exist between the movable conveyor segments?

Hi Jay, thanks for the compliments.

On all automotive assembly lines I know there is at least one section where the car is elevated. This is for the installation of the drive train (engine, gearbox, shafts) and axles from below. Sorry if this was unclear. I also assume that Toyotas new flexible assembly line is more of a vision, but I am not sure if they can implement it along the entire line. But then, Toyota has surprised me before.