Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Old Standard Layout for Toyota Plants

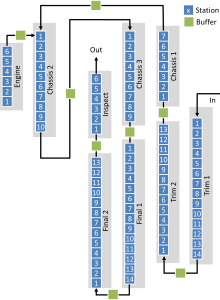

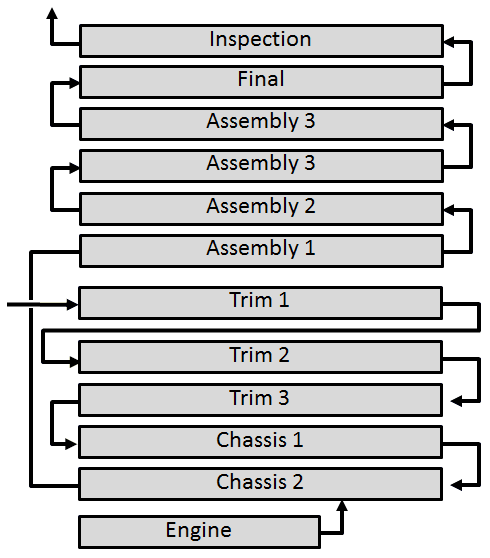

Traditionally, Toyota assembly lines consisted of three to four sub-lines, each about 300 meters in length. The trim line is for the installation of electrical parts. In the chassis line, the drive train, motor, exhaust, etc., are added. During the final line, bumpers, window glass, wheels, etc., are attached.

Layout Experiments at the Kyushu Plant 1992

For the new Kyushu plant constructed in 1992, this division was increased significantly. The line was split into a total of eleven self-contained subsections. Each section is about 100 meters long.

Changes in the Motomachi Plant 1994

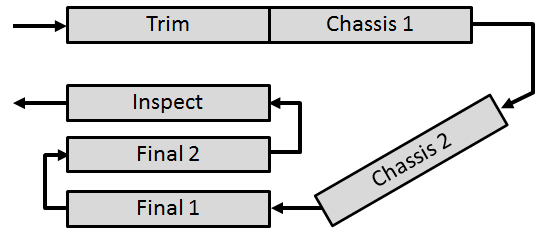

In 1994, the Motomachi line was also renovated. While not as radical as in Kyushu, some of the longer segments were split into smaller parts (one trim, two chassis, two final). Below is the 1994 layout of the Motomachi line:

New Layout Motomachi Plant

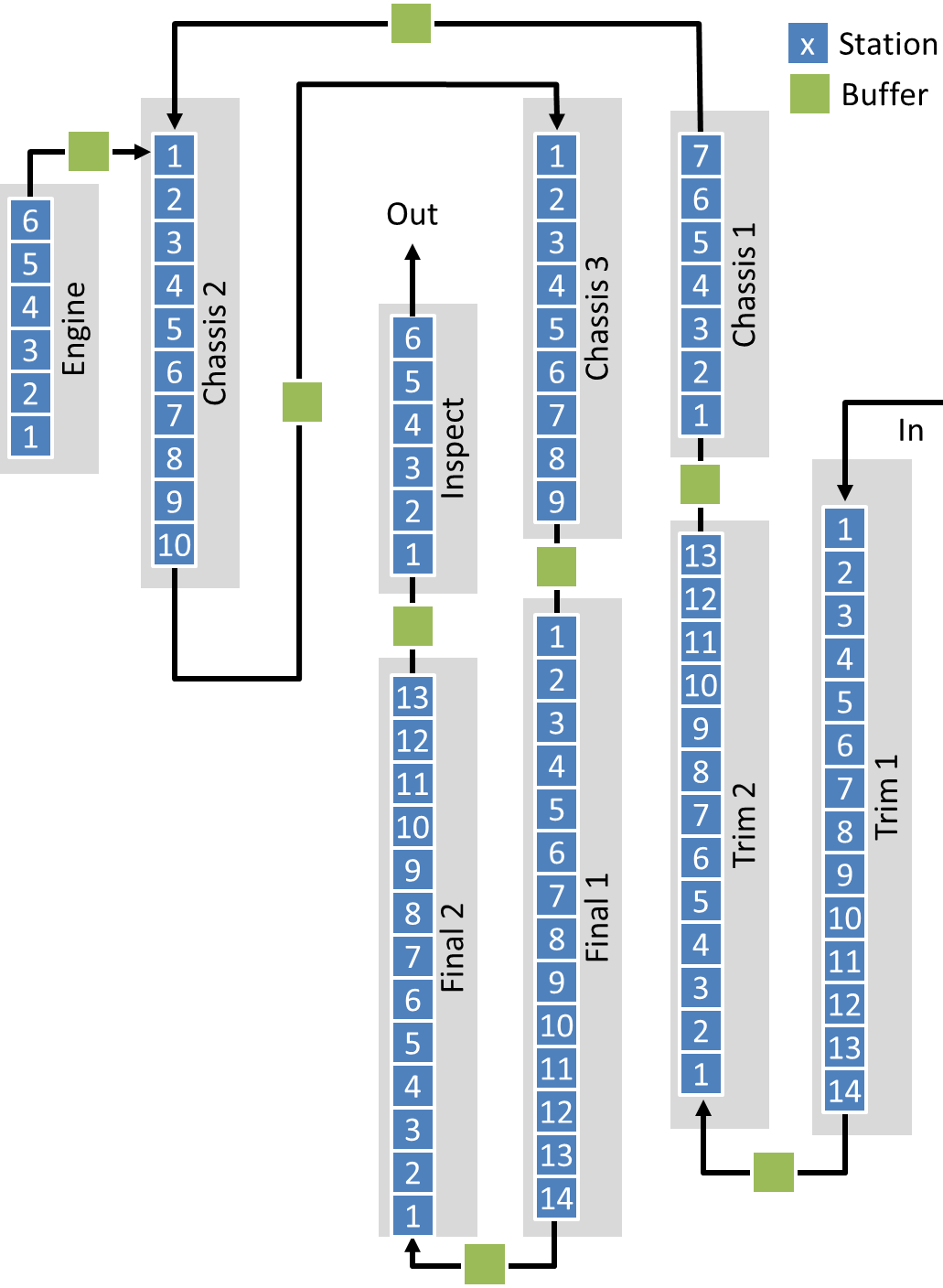

Below is the current (2014) layout of the Motomachi plant. Compared to the previous layout from 1994, this one contains many more individual segments divided by small buffer stocks (green boxes). With eight line segments, the plant still has less than Kyushu in 1992 (eleven segments), but more than in the 1994 renovation (six segments) and much more than before 1994 (three to four segments). Each small blue box below represents one station along the line or, in most cases, approximately one worker (not counting team and group leaders).

The exact number of people in the line depends also on the customer demand. One of the methods to adjust the output of the line is by adding or removing workers. When I observed the line, I measured a cycle time of 2:20 minutes per vehicle. The highly automated welding line was much faster, being able to produce one chassis in just over one minute. Interestingly, rather than cramming the line full with chassis (the Western way), Toyota used a pull system. New chassis were released only at the speed at which the assembly line could take them, hence there were always idle stations without any chassis in the welding line.

Advantages of the New Layout

There are different advantages for splitting the line. One major reason was worker motivation. At Toyota, every worker not only has the ability to stop the line, but must do so if there is a problem he cannot solve within one cycle time. However, in a long line, this means inconveniencing many other workers, not all of whom the worker has a social relation with. Hence, there is a feeling of guilt due to interrupting other people’s work, and hence a hesitation to stop the line.

With a shorter line, only about fourteen workers are involved in a line stop. Only problems longer than four or five cycle times affect other line segments; everything else is decoupled through the buffer stock between the lines. Hence, most line stops affect only a small social group of workers. Furthermore, the workers can temporarily increase speed and build up a small buffer of cars, and then use the time gained for a short five minute meeting to discuss current issues.

The second advantage is improved productivity. A problem does not stop the entire line, but only a segment. Hence, the risk of disruptions is spread and the productivity of the line is increased.

One question that popped in my mind: Why did Toyota wait until 1994 before they started to experiment with breaking the line into smaller segments. Supposedly Taiichi Ohno, the key force behind the Toyota Production System, was quite against that idea. Only after his death in 1990 did they dare to change things. After all, Ohno had quite a forceful personality. In any case, Toyota will continue to experiment with different approaches for assembly and other processes in order to reduce waste.

PS: If you would like to read more about history of manufacturing, then check out my book:

PS: If you would like to read more about history of manufacturing, then check out my book:

Roser, Christoph, 2016. “Faster, Better, Cheaper” in the History of Manufacturing: From the Stone Age to Lean Manufacturing and Beyond, 439 pages, 1st ed. Productivity Press.

Sources

- Takahiro Fujimoto, Evolution of Manufacturing Systems at Toyota, Productivity Press 2001.

- Yasuhiro Monden, Toyota Production System: An Integrated Approach to Just-In-Time, Productivity Press 2011.

Good

Toyota has a new benchmark assembly line in the Takaoka plant #2

Sure we know that the buffer and the shorter line can reduce the impact range. But, the lean philosophy is to step by step eliminate the buffer to reduce the inventory, and hence to expose the abnormalities, to challenge people to solve problems, to achieve people development and process improvement.

Why does Toyota go in reverse?

1. they don’t like challenges actually? Because people nature always like relax?

2. now they are facing much more abnormalities than ever before?

3. …