Total Productive Maintenance (TPM) is the best known framework for organizing maintenance. In this post I would like to dig deeper into its ideas and how it works. The principles of TPM are often arranged as “eight pillars,” although there are different views of what these eight pillars are. Let me give you an overview of these. In this post I will also look at the general problem of maintenance. In subsequent posts I will be going deeper into the individual pillars.

Total Productive Maintenance (TPM) is the best known framework for organizing maintenance. In this post I would like to dig deeper into its ideas and how it works. The principles of TPM are often arranged as “eight pillars,” although there are different views of what these eight pillars are. Let me give you an overview of these. In this post I will also look at the general problem of maintenance. In subsequent posts I will be going deeper into the individual pillars.

I will try to not only give a brief explanation how all the pillars work, but also give my opinion on which pillars I find useful and which one I don’t. There are some excellent elements in this framework that everybody should use on the shop floor, but there are also additional pillars that to me serve little purpose. In any case, I look forward to hearing your opinion in the comments.

The General Problem with Maintenance

Maintenance is sometimes neglected in manufacturing. The first problem is that the relation between maintenance and the effect of maintenance is ill understood. If you change the oil of your car, does it really improve the performance or prevent breakdowns? Sure, if you never change the oil, then eventually it will be bad for the vehicle. But what maintenance interval is sensible? Should you exchange every 15,000 kilometer, or every 40,000 kilometer? Or even less? The cost is often easy to determine based on labor and parts. For your car this would be the oil, the oil filter, etc., as well as the labor for exchanging the oil.

Maintenance is sometimes neglected in manufacturing. The first problem is that the relation between maintenance and the effect of maintenance is ill understood. If you change the oil of your car, does it really improve the performance or prevent breakdowns? Sure, if you never change the oil, then eventually it will be bad for the vehicle. But what maintenance interval is sensible? Should you exchange every 15,000 kilometer, or every 40,000 kilometer? Or even less? The cost is often easy to determine based on labor and parts. For your car this would be the oil, the oil filter, etc., as well as the labor for exchanging the oil.

But the benefit is much harder to figure out. Let’s take your car as an example. How often will your car have problems? What kind of problems? Is it just a higher fuel consumption, or will the entire engine have to be scrapped due to a lack of oil. Does the breakdown happen when you just by chance drive to the mechanic anyway, which would be less of a hassle, or does the breakdown happen when you are on your way to an interview for your dream job, which would be extremely detrimental?

But the benefit is much harder to figure out. Let’s take your car as an example. How often will your car have problems? What kind of problems? Is it just a higher fuel consumption, or will the entire engine have to be scrapped due to a lack of oil. Does the breakdown happen when you just by chance drive to the mechanic anyway, which would be less of a hassle, or does the breakdown happen when you are on your way to an interview for your dream job, which would be extremely detrimental?

Given sufficient data points, you can eventually describe these relations statistically. Some industries have better data, like automotive or aviation, simply because they collect plenty of data and accidents may be extremely expensive. But getting sufficient data points takes time, and a small company may never have enough data to understand a machine before the machine is replaced by a new one. Hence, a cost-benefit analysis is difficult to to for maintenance.

The second problem is the delay between maintenance (or lack thereof) and the improved uptime (or lack thereof). This can easily be years. For example, if you buy a used car, you probably should look at the service history. Not only does this delay make the relation more difficult to understand, but in industry the person paying for the maintenance and the person benefiting from it may be different. It is a dirty trick by one manager to look good by saving money on maintenance but leaving the problem of deteriorating equipment to his successor three years later. At the same time, you can’t blame him either, since the relation is also difficult to understand. It does not help that maintenance consultants almost always favor more maintenance, even though they are (often) right. Overall, determining the right amount of maintenance is usually a rough and error-prone guesswork at best.

The second problem is the delay between maintenance (or lack thereof) and the improved uptime (or lack thereof). This can easily be years. For example, if you buy a used car, you probably should look at the service history. Not only does this delay make the relation more difficult to understand, but in industry the person paying for the maintenance and the person benefiting from it may be different. It is a dirty trick by one manager to look good by saving money on maintenance but leaving the problem of deteriorating equipment to his successor three years later. At the same time, you can’t blame him either, since the relation is also difficult to understand. It does not help that maintenance consultants almost always favor more maintenance, even though they are (often) right. Overall, determining the right amount of maintenance is usually a rough and error-prone guesswork at best.

Overview of the Pillars

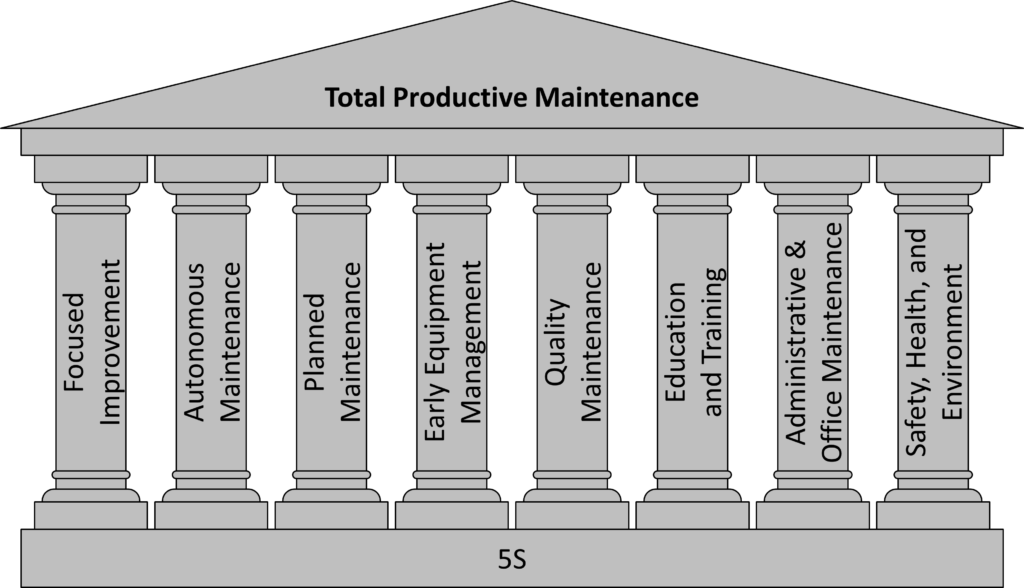

Now, let’s have a look at the eight pillars of TPM. Frameworks are often arranged as houses with pillars, foundations, and so on. There is the house of lean, with three columns and the three pillars of SCRUM. There are some graphs with the four pillars of Six Sigma, and so on. Pillars are used to give these ideas weight, although sometimes it feels more like a sales tactic to me.

Now, let’s have a look at the eight pillars of TPM. Frameworks are often arranged as houses with pillars, foundations, and so on. There is the house of lean, with three columns and the three pillars of SCRUM. There are some graphs with the four pillars of Six Sigma, and so on. Pillars are used to give these ideas weight, although sometimes it feels more like a sales tactic to me.

TPM also has pillars, and an unusually high number of them too. In the English literature, there are usually eight pillars of TPM. Originally there were only seven, but the the Japan Institute of Plant Maintenance (JIPM) expanded them to eight. Additionally, 5S is also often listed as the foundation of TPM. Let me give you an overview of the most common version of the pillars:

- Focused Improvement (meaning Continuous Improvement)

- Autonomous Maintenance

- Planned Maintenance

- Early Equipment Management (somewhat similar to Design for Maintenance)

- Quality Maintenance (which in lean would be called Jidoka)

- Education and Training (which in lean would be part of standardization)

- Administrative & Office Maintenance

- Safety, Health, and Environment

In Japanese, these pillars would be as follows:

- Focused Improvement is Kobetsu-Kaizen (個別 改善 for individual; separate; personal; case-by-case and betterment; improvement).

- Autonomous Maintenance is Jishu Hozen (自主 保全 for independence; autonomy; self-reliance and preservation; integrity; conservation; maintenance).

- Planned Maintenance is Keikaku Hozen (計画 保全 for plan; project; schedule; scheme; program; and preservation; integrity; conservation; maintenance).

- Early Equipment Management is Shoki Kanri (初期 管理 for early; initial stage and control; management).

- Quality Maintenance is Hinshitzu Hozen (品質 保全 for quality and management).

- Education and Training is Kyōiku Kunren (教育 訓練 for education; schooling; training; instruction; teaching; upbringing and training; drill; practice; discipline).

- Administrative & Office Maintenance is Kanri kansetsu bumon katsudō (管理 間接部門活動 for control and internal division; back-office section; indirect department).

- Safety, Health, and Environment is Anzen and Kankyō Kanri (安全 for safety; security, 環境 管理 for environment and control; management).

Variants of the Pillars

However, there are also other versions of the eight pillars. They often differ not only in sequence, but also in the names and the content. For example, what in English is called Focused Improvement, is in German Continuous Improvement (which for me as a lean guy feels more normal). The Early Equipment Management focuses on design for maintenance, but this is sometimes replaced by Ramp Up, focusing more on ramp up than on machine design.

However, there are also other versions of the eight pillars. They often differ not only in sequence, but also in the names and the content. For example, what in English is called Focused Improvement, is in German Continuous Improvement (which for me as a lean guy feels more normal). The Early Equipment Management focuses on design for maintenance, but this is sometimes replaced by Ramp Up, focusing more on ramp up than on machine design.

In other sources you can also find only seven pillars of TPM. Some of these dropped the safety, health, and environment aspect (and I am always unhappy if safety is overlooked), others dropped the early equipment management. There are even sources with only five pillars, dropping the administrative part, and putting continuous improvement and safety as foundations instead of pillars (where I like them much better). If you want more pillars, this is not a problem either. There is a variant of TPM with nine pillars also available, adding logistics. There are even completely different structures and pillars that claim to be TPM, with pillars like “To reduce forced deterioration” or “To reduce natural deterioration.”

There are many more versions of the pillars of TPM. If you’re curious, just do a google image search for the “Pillars of TPM.” The points I’m getting at are that there is no fixed canon of pillars, and everybody likes drawing houses. However, despite a lack of structure, and besides an overlap of some of these topics, TPM contains lots of useful ideas worth exploring. In my next posts I will go deeper into the different pillars of TPM. Now, go out, think about how you can improve your maintenance, and organize your industry!

There are many more versions of the pillars of TPM. If you’re curious, just do a google image search for the “Pillars of TPM.” The points I’m getting at are that there is no fixed canon of pillars, and everybody likes drawing houses. However, despite a lack of structure, and besides an overlap of some of these topics, TPM contains lots of useful ideas worth exploring. In my next posts I will go deeper into the different pillars of TPM. Now, go out, think about how you can improve your maintenance, and organize your industry!

PS: Many thanks to Leandro Barreda and Gil Santos for nudging me to write about maintenance.

Series Overview

- A Brief History of Maintenance

- What Are the Goals of Maintenance?

- An Overview of the Eight Pillars of Total Productive Maintenance

- The Pillars of TPM – Focused Improvement

- The Pillars of TPM – Autonomous Maintenance

- The Pillars of TPM – Planned Maintenance

- The Pillars of TPM – Early Equipment Management

- The Pillars of TPM – Quality, Training, Administration, and Safety

- The Pillars of TPM – The Missing Pillar Reactive Maintenance?

Hy Christoph,

As a former JMAC I have to say that there is one reference in TPM that coming from JMA, because at origins of formalization with DENSO, the only real TPM world award since decades

So let me say there are no several versions of TPM, just one that you show it with 8 pilars, not 5 or 7 or others titles and interpretations. We should stick to the original, most completed and efficient form

But it is also true that companies can choose to work on what we call core TPM (first three pilars) because the most quick benefits and limited resources, could also add early equipment management or training or quality pilar. Companies could choose to work on as many pilars as they like. TPM is a system and you can have a complete benefit when you apply it entirely. You are obliged to work on the entire system just if you want to candidate for TPM AWARD.

Anyway nice to see TPM part of your interest because as an old JMAC said “TPM as Lean tackle the losses”

One more comment about the first pilar, I learned that the meaning of pilar 1 Focused improvement is the reduction of the biggest losses of OEE. Together with pilars 2, 3 and 4 they are supposed to insure a very high performance of the equipment

Virgil

Hi Virgil, interesting comment! I think historically TPM had only seven pillars, and an 8th one was added eventually. In a later post, I have a critical review of the 8 pillars, and end up with suggesting much less pillars. (putting a lot in the foundation, removing some, and even adding a new pillar that I think is overlooked). Will be interesting to hear your view on that when it comes out. Cheers!

First off thank you for providing consistently interesting and high quality content. I suppose TPM, gets passed over as is looking at equipment that makes product rather than the product itself and its great to see this core aspect of lean covered. As a reliability engineer there is a cost balance to where you decide to invoke what maintenance strategy. Of course that does change as costs change and Industry 4.0 has certainly played a major role in making PdM more attractive.

Whilst training and office TPM are overlooked. I see them as the standardised work and stock management aspects of TPM that ensure people know what they are doing and the right goods and tools area available at site at the right time.

Hi Jonathan, Maintenance is important, it is just hard to determine how much you should do. Interesting that you say Training is standardized work, I had exactly the same conclusion (more on that in a later post of this series on maintenance).

Hello Chris,

Maintenance is something that is often overlooked when purchasing a car. Novices don’t realize that some cars have a history of problems and often need maintenance. In some countries, they don’t implement the safety pillar and I believe that’s not right. Depending on the car and the kind of maintenance, the job could cause harm if done wrong. Do you believe that safety should be higher on the list in terms of the higher-risk maintenance jobs?

Jason

Hi Jason, Safety is important. However, as I will explain in a later post, I think having safety under the umbrella of maintenance is not the right way. I rather have safety as a main topic, where maintenance is one of the tools to create safety.

Excellent work as usual. Great point of view about maintenance. I like it when you’re talking about maintenance as a jidoka in the manufacturing. Never thought about that or in that way.

Hi Christoph, I think it would make sense to make a discrimination between “maintenance operational” pillars and those which are “support pillars”. Autonomous Maintenance, Planned Maintenance, Quality Maintenance and Early Equipment Management are in the first category; the remaining pillars in the second.

Hello Süleyman, I also agree that the pillars are of varying quality. In a later post I will discuss how I would have rearranged the pillars, and even added one that I find sorely missing in the typical 8 pillars.

Hello Christoph, after analyzing your post I began thinking about the importance of the final pillar of Safety, Health, and Environment and its relevance weighing heavier now than in the past. Especially with larger manufacturing companies, considering the automobile industry, they are pledging towards safer cars not just for the drivers, but also the environment. I believe both human & environmental safety will continue to be weighed stronger in the future of total productive maintenance.

Hi Dylan, safety is important. Safety is VERY important. However, due to its importance I am not sure if I see it as a pillar of TPM, but an overarching topic on its own right. With respect to the pillars of TPM, I would see it as a foundation, not a pillar. More on that in a later post.

Great post as usual from Chris.

often, and in particular in OEM plants and suppliers i see TPM as something which reduces OEE. I have noticed that when the line is standing i get the response “we are doing TPM” and “it does not effect OEE’ as we dont count the planned TPM time. What!!!!!!!!!.

My conclusion is, based on my humble experience from Toyota, TPM is not “Time for Peanuts & Melons”, it has to be acted on according to standard work and 2nd points, we do include it in OEE for the simple reason to make sure it really is short.

Hello Mark, I totally agree, and also would include TPM activities as part of the OEE (unless it is during a weekend or so if there is no manufacturing in t he plant anyway). But as soon as jobs have to wait due to TPM, it affects the OEE.

Hi Christoph,

After reading your post, I have been thinking more about maintenance and how it can be easily rejected like you said. I think your car example really helped me to understand this to the best of my ability. I can see how determining the perfect amount of maintenance can lead to error because it is hard to predict that, but using statistical tools and data analyses can definitely get a good estimate. The safety, health, and environment pillar plays a big role for the automobile industry. Having productive and effective maintenance can help cars to be safe for the people who drive them and the environment. Improving and organizing maintenance is very important, and something I will be more aware of moving forward. Thanks for sharing! -Joe