Employment is an exchange of work for money. In my last post I showed a few tricks on how operators keep management in the dark about the true workload. However, management is also not giving out all the details on their side either. Naturally, the true value of the work is difficult to assess. Even if companies could know exactly how much each employee contributes to the success, they probably would keep this information top secret.

Employment is an exchange of work for money. In my last post I showed a few tricks on how operators keep management in the dark about the true workload. However, management is also not giving out all the details on their side either. Naturally, the true value of the work is difficult to assess. Even if companies could know exactly how much each employee contributes to the success, they probably would keep this information top secret.

More interesting, however, is the value of the target workload, where operators are able to work continuously at 130% capacity without problem. The following are my own thoughts, as I have never seen these conclusions anywhere else before.

The 100% Workload

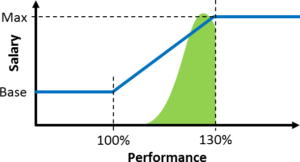

On many shop floors, workers receive performance-based pay. There are different ways to determine the target speed, often through predetermined motion time systems.

Usually, there is a base salary if the worker performs at 100% of the target speed or less. If the worker is faster than the target speed, he or she will get more money. In most cases, this is also capped at an upper end, often around 130%. While there are also systems without a cap, they are rare because they all too often generate large quantities of bad quality.

Predetermined Motion Time Systems

Predetermined motion time systems date back to Frank Gilbreth and his 18 Therblings around 1910, although they are forgotten nowadays, and Methods-Time Measurement is probably the most common approach.

Predetermined motion time systems date back to Frank Gilbreth and his 18 Therblings around 1910, although they are forgotten nowadays, and Methods-Time Measurement is probably the most common approach.

Those systems are based on thousands upon thousands of measurements of small movements. If you pick up a screw, you look up in tables how long it takes to reach a certain distance, how long to grab an item similar to the screw, and how long to move the item over a distance somewhere else. Overall you break down the movement into individual steps, look up the time for each step, and calculate the total time. While these calculations take quite some time for more complex tasks, at the end you have a time that corresponds to a 100% workload.

What You Would Expect

Hence, you would expect that the true performance of the workers is distributed somewhere around the 100% workload. Sometimes people are faster, sometimes slower, but overall they should be somewhere in the vicinity of the 100% workload.

What You Actually Get

In reality, however, the workers are able to perform consistently near or at the salary cap (i.e., they constantly work at 130% of what would have been expected from them).

This has been my observation in many, many plants. I also think that many of the more experienced shop floor managers know this too. The operators probably could work much faster, but for reasons described in my last post they will not exceed this upper limit. The few times when the operators fail to reach this 130% is usually due to circumstances out of their control (e.g., breakdowns or missing material).

Is 130% the New 100%?

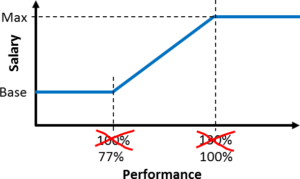

Okay. If workers are consistently able to achieve 130%, wouldn’t it make sense to update the tables and times so that what was formerly 130% is now 100%?

Okay. If workers are consistently able to achieve 130%, wouldn’t it make sense to update the tables and times so that what was formerly 130% is now 100%?

We could even keep the salary at the same levels by not changing the graph. The worker would still get the same salary for the same work, as before, except the old 130% is now 100% and the old 100% is now 77%. Hence, there should be no difference in salary.

Reward vs. Punishment

While there is no difference in salary regardless of which level you call 100%, there is a big difference in the view of the operators.

While there is no difference in salary regardless of which level you call 100%, there is a big difference in the view of the operators.

According to Herzberg’s two-factor theory, there are some things that motivate (motivators), whereas other things don’t motivate but have to be there to avoid demotivation (hygiene factors). In this view, money clearly is a hygiene factor. Giving more money will motivate only for a short time (around 3 months) before the effect vanishes. However, reducing the salary will undermine morale and demotivate an employee for a long time.

Hence, if you start with the old 100% and increase salary for performance up to 130%, you don’t really get much motivation, but you don’t demotivate either. However, if you start at the “new” 100%, and reduce salary if it is not reached, operators will be pissed. No matter that they get the same money as before. In one system it is seen as an increase, in the other it is seen as someone taking away their money.

For the Sake of Peace …

I am not sure how many managers are aware of the difference between the official 100% and the true 100%. Yet, even if you know, you would be well advised not to touch it. Readjusting the 100% will bring no benefit, but it will result in lots of demoralized employees. Hence, for the sake of peace, everybody pretends that 77% is actually 100%. You should keep in mind that it is most likely not, but you should not touch it if you can avoid it.

I am not sure how many managers are aware of the difference between the official 100% and the true 100%. Yet, even if you know, you would be well advised not to touch it. Readjusting the 100% will bring no benefit, but it will result in lots of demoralized employees. Hence, for the sake of peace, everybody pretends that 77% is actually 100%. You should keep in mind that it is most likely not, but you should not touch it if you can avoid it.

This post may have been a bit philosophical, but for me the main lesson is about the effort and the pretense that goes into the workload targets from the employers’ side. The goal is that everybody can walk away from the work and money negotiation feeling good. It makes no difference money wise, but it makes a lot of difference for morale. So, go out, motivate your people, and organize your industry!

Achieving 100% performance relies on many standards being observed: standard conditions, standard operator, standard parts, standard settings, standard effort applied to a standard operation …and then we are able to make a standard product in standard time, which we can then use to determine tact etc.

All too often there is a lot of emphasis on achieving Std Time without seeing this as a result of achieving the others – expecting above standard effort to compensate for non-standard parts, for example.

I find it unlikely that a sustained 130% performance could be achieved where standards have been set well. I my youth I recall achieving maximum bonus for an unskilled team job which required working like stink for about 3 hours to achieve the target which would realise maximum bonus for a four-hour deployment, in the expectation that we would rest for the final hour. We were most upset to find on payday that we had been paid maximum bonus for the three hours …and booked elsewhere for the final hour with no bonus! We never did that again…

Thanks, Steve. When your company calculated your bonus based on only three yours, they may have simply made a mistake, or intentionally optimized their cost. In any case, the result was the same, workers never repeated this “fault”. Great example 🙂

Deming in his 14 points says elimnate quotas. If the standards are done correctly and it has been demonstrated that they are achievable, then you have a value-added process. Lean is a hand shake between management and employees. They should be looked at as associates and not subordinates! All too often management does not practice lean concepts in their daily lives on the job and expect others to do so.

To your point, make more-quantitative measures rather than qualitative is surely opposite of what true Lean practices are and mean. Why not get it right the first time and then through continuous improvement engage your workforce with management to continuously imporve the processes to shorten the order to cast cycle. A true partnership is realized when everyone is working together towards a common goal!

In Lean we say we should establish a high level of agreement and not to walk away from the meeting table feeling that your voice has not been heard and or valued. We need more organizational training and less analytical analysis. It is not the people that are at fault, it is the PROCESS that is broken. No one comes to work wanting to do less. They just want an opportunity to be heard and be part of the rewards that can be achieved!

Hi Dennis, I agree with you. While lean of course needs to know how much can be produced per hour, we do not need to pay according to pieces. Historically, payment was often solely based on the number produced (no production … no salary). Nowadays a base salary and a upper cap are common. Moving away to a fixed salary would be great. Management, however, would fear that the employees would then just slack off. There is still a lot of distrust between white collar and blue collar in both directions, and often justified based on prior experience on both sides. For this to work you need a lot of trust. In larger or older companies this will be next to impossible, since both sides have a lot of “history” 🙁

Very Knowledgeable and practical explanations . Very good article .

Excellent article, thanks. Understanding the weak/short-term positive incentive vs long-term steep negative incentives is so key in assessing the best decision when it comes to changing pay structure.

That’s a great point on trust being essential for the white-blue collar relationship to work out beneficially, and with companies where there’s bad history it can be so ingrained in the culture…

Unless it has changed in recent years, about 2/3 of German production workers are paid on a piece rate, an archaic approach that has been abandoned in most industrialized countries. It came to my attention when I saw an operator swear at a machine that wouldn’t start correctly. The machine set the pace of production but he was the one to suffer if it malfunctioned. In that plant too, everybody produced 140% of the standard, set by REFA.

Operators should be paid a basic wage based on time, with supplements based on grade, seniority, ability (as per the skills matrix), and performance, measured on more than output quantity.