All About Pull Production is a practical guide for anyone looking to implement pull systems. It focuses on practical application and values functionality over theory, albeit it explains the underlying relations. It is not a high-level philosophical discussion of lean, but a book to help you roll up your sleeves and get the job done. It is written for the practitioner. If you are working in production or logistics and want to implement pull, then this book is for you. It also serves as a useful reference for students and researchers of lean manufacturing. With a foreword by John Shook.

All About Pull Production is a practical guide for anyone looking to implement pull systems. It focuses on practical application and values functionality over theory, albeit it explains the underlying relations. It is not a high-level philosophical discussion of lean, but a book to help you roll up your sleeves and get the job done. It is written for the practitioner. If you are working in production or logistics and want to implement pull, then this book is for you. It also serves as a useful reference for students and researchers of lean manufacturing. With a foreword by John Shook.

The book has received the prestigious Shingo Publication Award on October 2022.

The book has received the prestigious Shingo Publication Award on October 2022.

See here for the Translations of All About Pull Production into different languages.

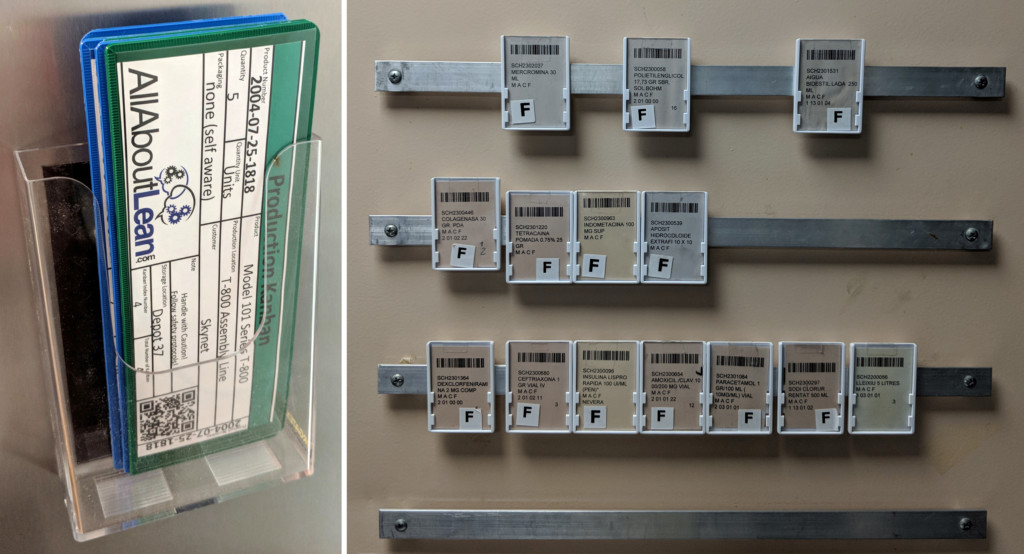

Roser, Christoph. All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. 441 pages: AllAboutLean.com Publishing 2021.

- Available on Amazon as a Hardcover (Case Laminate) ISBN 978-3-96382-036-6

- Available on Amazon as a Paperback ISBN 978-3-96382-028-1

- Available on Amazon as an EBook ISBN 978-3-96382-029-8

- Available on Barnes&Noble as a Hardcover (Jacketed) ISBN 978-3-96382-038-0

- f you want to buy outside of the Amazon Ecosystem, the paperback and the hardcover (jacketed) is also available at Barnes&Noble and many other online or brick-and-mortar retailers, printed through IngramSpark

- The above Amazon links should lead you to your closes Amazon store. Just as a backup, here are the links to the different Amazon stores that I know of where my Book is also available: Australia, Brasil, Canada, (Not yet China), France, Germany, India, Italy, Japan, Mexico, Netherlands, Poland, (Not yet Saudi Arabia), Singapore, Spain, Sweden, Turkey, UK, United Arab Emirates, and the USA.

Praise for All About Pull Production

In this book you will find many techniques and tools that will help you reconfigure your supply chain operations. But more importantly, by exploring numerous approaches and methods, this book will challenge you to rethink your strategy, to reconsider what your supply system needs to accomplish and why. This book provides you the means to create supply systems for the rapidly evolving complexities of the twenty-first century, anywhere, in any industry.

John Shook

Chairman, Lean Global Network

Prof. Roser is the go-to source for anything about lean. With this comprehensive book on pull production he has written an authoritative work. Highly recommended for anyone interested in getting to the heart of Toyota’s pull principle.

Dr. Torbjørn Netland

Professor of Production and Operations Management, ETH Zürich

This book explains pull production very well and in an excellent style. The book definitely demystifies pull. Without doubt, the book will be the go-to guide for both beginners and experienced practitioners.

Cheong Tsang

Bosch Plant Manager (Retired)

Prof. Dr. Roser is an irreplaceable professional in teaching and studying production management systems. He has both brilliant academic talent as a researcher and rich technical skills as a practitioner and a consultant. He has long experience and much knowledge in both Europe and Japan. Readers will definitely obtain a lot of valuable insights and new ideas from his book on pull production.

Dr. Masaru Nakano

Professor, Keio University; Former Toyota Manager

This is by far the best in-depth exploration of pull. It is amazingly comprehensive, including warnings, common errors, and applicability of various pull systems. I am sure that it will become THE standard reference book on pull systems.

Dr. John Bicheno

Emeritus Professor of Lean Enterprise, University of Buckingham

According to the lean principle “Flow where you can, pull where you can’t”, Christoph Roser presents production control methods based on the pull principle in a comprehensive and practice-oriented way. This book is worth reading for everyone dealing with mura (i.e. variability in value streams), and is my recommendation for students and industry practitioners alike.

Dr.-Ing. Jochen Deuse

Professor, Head of Institute of Production Systems, TU Dortmund University; Director Centre for Advanced Manufacturing, University of Technology Sydney

The book provides well structured, in depth insights in the application of pull systems, from Kanban to less-known but powerful alternatives. The book is a valuable source for students and practitioners in industry, from lean experts to production managers.

Dr.-Ing. Ralph Richter

Former Head of the Bosch Production System and Plant Manager at Bosch

With this deeply researched and considered book, Prof. Roser goes beyond the simple explanations of pull to reveal pull production in its compelling simplicity. The results provide a convincing case and trusty guide.

Peter Willats

Professor, University of Buckingham, Co-Founder, Kaizen Institute of Europe

This book is so comprehensive in its scope, anyone considering a pull system should read it to make sure they have made the correct choice. So many are only aware of the kanban system and consider it the default. This book offers options for them to consider in light of their needs.

Mark Warren

Manufacturing Engineer and Production Historian

What you have put together in this book is amazing–this may become your magnum opus in due course! It’s going to be a great reference resource for practitioners and academics.

Dr. Rajan Suri

Emeritus Professor of Industrial Engineering, University of Wisconsin-Madison, Inventor of POLCA

This book is excellent material for understanding and using pull production. It is very informative and written in a very polite and pleasant personal style with good reflections and clarifications.

Dr. Björn Johansson

Professor of Sustainable Production, Chalmers University of Technology, Sweden

Reading Sample TOC and Chapter 1

You can download the table of contents and chapter 1 as a reading sample: All About Pull Production Reading Sample. This sample includes the front matter including foreword and table of content and Chapter 1–3 of the actual book. The sample is the first 84 pages out of 441 pages for the entire book. The file size is 2.28 MB. Formatting is as for the paperback version.

You can download the table of contents and chapter 1 as a reading sample: All About Pull Production Reading Sample. This sample includes the front matter including foreword and table of content and Chapter 1–3 of the actual book. The sample is the first 84 pages out of 441 pages for the entire book. The file size is 2.28 MB. Formatting is as for the paperback version.

Table of Contents

- Foreword by John Shook

- Acknowledgements

- Chapter 1: Introduction

- Chapter 2: Fundamentals of Pull Systems

- Chapter 3: Comparison of Different Pull Systems

- Chapter 4: FIFO and Other Limited Buffer Inventories

- Chapter 5: Kanban

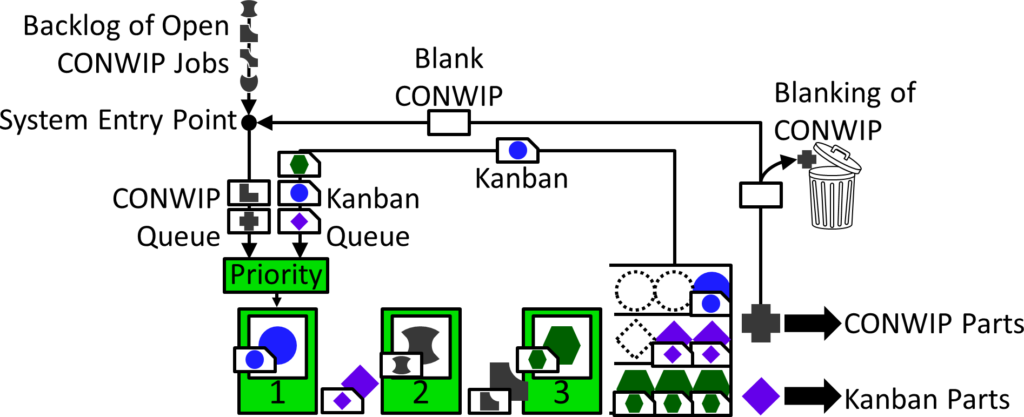

- Chapter 6: CONWIP

- Chapter 7: POLCA

- Chapter 8: Reorder Point

- Chapter 9: Drum-Buffer-Rope

- Chapter 10: Pull Systems Outside of Manufacturing

- Chapter 11: Pull System Layout

- Chapter 12: Pull System Ramp-Up

- Chapter 13: Pull System Maintenance

- Chapter 14: Summary

- Appendix A: Table of Variables

- Appendix B: Value Stream Mapping Symbols

- Appendix C: COBACABANA

- Appendix D: Recommended Reading

- Bibliography

- Image Credits

- About the Author

Errata

Nothing is perfect, not even this book. You surely know that if you write anything, you will find some mistakes whenever you look into it again. This is of course embarrassing, but I don’t want to hide my mistakes but instead want to correct them. Hence, please do not see this list of errata as a flaw but as a sign of a good publication. Anyway, here is my list of Errata that I have found so far.

Version 1.00 published 03.04.2021 1st Edition

- Page 34 Chapter 2.6.6 “Similarly, you could use pull if supply is exceedingly low, albeit I would advise against it for similar reasons.” should be “Similarly, you could use push if supply is exceedingly low, albeit I would advise against it for similar reasons.“

- Page 42 Chapter 3.1.1 “Hence, with make-to-stock, the goal is to minimize the time between receiving the order and delivering the product, while keeping the system utilization reasonably high.” should be “Hence, with make-to-order, the goal is to minimize the time between receiving the order and delivering the product, while keeping the system utilization reasonably high.“

- Page 55 Chapter 4 “Figure 25 shows a basic example where the buffer between stations is limited to a maximum of five spaces.” should be “Figure 25 shows a basic example where the buffer between stations is limited to a maximum of four spaces.”

- Page 67 Chapter 4.4.2 “If the adjacent buffer is downstream, the buffer needs at least ten minutes’ worth of empty space.” should be “If the adjacent process is downstream, the buffer needs at least ten minutes’ worth of empty space.”

- Page 108 Chapter 5.3.2.2 “Figure 70 shows an example. The balls are below their minimum.” should be “Figure 67 shows an example. The balls are below their minimum.“

- Page 164 Chapter 5.4.3.3.3 “Table 12 shows an overview of the elements for the number of production kanbans…” should be “Table 12 shows an overview of the elements for the number of transport kanbans…“

- Page 218/219 Chapter 6.4.4.2.1 “Dividing the number of jobs you have or want to have in your system…” should be “Multiplying the number of jobs you have or want to have in your system…“

- Page 228 Chapter 6.4.6.3.1 “Hence, the total replenishment time is 21 769.2 seconds,…” should be “Hence, the total replenishment time is 21 889 seconds,…“

- Page 239 Chapter 6.7.5 “Hence, do not use a combined upper inventory limit for different make-to-order parts!” should be “Hence, do not use a combined upper inventory limit for different make-to-stock parts!“

- Page 252 Chapter 7.4.3 “The lead time is simply the sum of the individual lead times of 24 hours for process A and 8 hours for process B, plus…” should be “The lead time is simply the sum of the individual lead times of 24 hours for process P1 and 8 hours for process P2, plus…“

- Page 263 Chapter 8.1 “Every time you order one item, you drop below your reorder point…” should be “Every time you consume one item, you drop below your reorder point…“

- Page 278 Table 26: “Orders per Year (Wheels)” should be “Orders per Year“

- Page 282 Table 31 the labels of the rows “Peak Customer Demand” and “Large Customer Order” should be switched

- Page 306 Chapter 10.1.2 Figure 151 should instead of “OP1” & “OP1” have “OP1” & “OP2“

- Page 325 Chapter 11.1.8 “Due to the pull aspect, the overall inventory in the segment can also spin out of control if too much is pushed into the system simultaneously.” should be “Due to the push elements, the overall inventory in the segment can also spin out of control if too much is pushed into the system simultaneously.“