With the KPI groups safety, quality, productivity, and cost, this series on the Toyota KPI dashboard has covered the main topics. However, there is more. Not always but often you can also find a section on human resources (HR) development. Yet, these are usually not KPI, but more organizational topics that may be part of the daily shop floor meeting. Below are some examples of how this section could look, although this may vary quite a bit among different Toyota plants. Let’s have a look:

With the KPI groups safety, quality, productivity, and cost, this series on the Toyota KPI dashboard has covered the main topics. However, there is more. Not always but often you can also find a section on human resources (HR) development. Yet, these are usually not KPI, but more organizational topics that may be part of the daily shop floor meeting. Below are some examples of how this section could look, although this may vary quite a bit among different Toyota plants. Let’s have a look:

Training

The Limits of Work Standards

Work standards are the backbone of continuous improvement because you need a standard to maintain what you have already achieved. But standards are not easy. A standard should explain everything in sufficient detail without being too detailed…and that is a fine line to walk. The key to the problem, but also to the solution, is the worker who uses the standard. Let me show you.

Work standards are the backbone of continuous improvement because you need a standard to maintain what you have already achieved. But standards are not easy. A standard should explain everything in sufficient detail without being too detailed…and that is a fine line to walk. The key to the problem, but also to the solution, is the worker who uses the standard. Let me show you.

Work Improvement before Equipment Improvement

When improving a system, Western engineers love to take the technical approach and to optimize the machines and tools. However, at Toyota this is seen differently. At Toyota, they try to address a problem by first training the people, followed by improving the standards and the layout, before improving the equipment and finally twiddling with the design. Let’s have a closer look at how Toyota is approaching improvements.

When improving a system, Western engineers love to take the technical approach and to optimize the machines and tools. However, at Toyota this is seen differently. At Toyota, they try to address a problem by first training the people, followed by improving the standards and the layout, before improving the equipment and finally twiddling with the design. Let’s have a closer look at how Toyota is approaching improvements.

How to Learn Lean

Lean manufacturing can help you and your company greatly. But how do you learn lean? Of course, there are plenty of Six Sigma lean black belts and other certificates available online, but do they really make you understand lean? In this post I have some suggestions on how to learn lean. These can befollowed by people with access to an actual shop floor to work on. However, I have also included suggestions for people, e.g. students, that do not have access to a shop floor. In this case, you can do … let’s call it “Home Improvement“. Let’s have a look at some suggested actions for learning how to do lean!

Lean manufacturing can help you and your company greatly. But how do you learn lean? Of course, there are plenty of Six Sigma lean black belts and other certificates available online, but do they really make you understand lean? In this post I have some suggestions on how to learn lean. These can befollowed by people with access to an actual shop floor to work on. However, I have also included suggestions for people, e.g. students, that do not have access to a shop floor. In this case, you can do … let’s call it “Home Improvement“. Let’s have a look at some suggested actions for learning how to do lean!

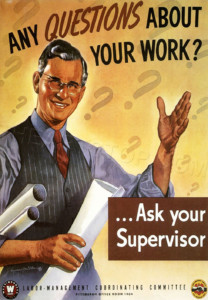

JI: Training within Industry – Job Instructions

Arguably the most successful module of Training within Industry is Job Instructions, or JI for short. JI has a precise focus on one topic: how to train your workers. The method is very simple and basic but works well.

Arguably the most successful module of Training within Industry is Job Instructions, or JI for short. JI has a precise focus on one topic: how to train your workers. The method is very simple and basic but works well.

Of course, there are some limitations. The process works well with pretty much any type of work, but it is best done one-on-one, as it was intended. It is not well suited for classroom teaching of larger groups; the trainer does need to invest time and attention to every individual student. But overall a very useful method. This is the second in a series of five posts on TWI.

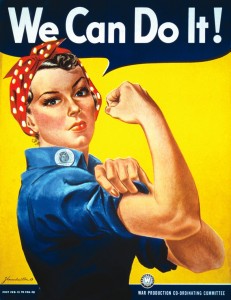

Training within Industry – TWI – Oldies but Goldies

Training within Industry – or TWI for short – was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s, they are still very relevant. In my view, they are pure gold if you have to manage a shop floor. It is to me the best overarching system for training and managing workers, and it significantly influenced Toyota.

Training within Industry – or TWI for short – was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s, they are still very relevant. In my view, they are pure gold if you have to manage a shop floor. It is to me the best overarching system for training and managing workers, and it significantly influenced Toyota.

While technology has changed a lot since 1945, people have not. The methods of TWI still work, and can really help you to improve. Even better, the original US government documents from 1945 are all in public domain. Let me introduce you to TWI. This is the first in a series of five posts on TWI.

A Small Dice Game for the Kingman Formula

In a previous post I wrote about the relation between utilization, fluctuation, and waiting time, and its approximation by the Kingman formula. Let me show you a quick and easy dice game where we simulate a supermarket checkout to let participants experience the effect of utilization, fluctuation, and the (worse) combined effect of both.

In a previous post I wrote about the relation between utilization, fluctuation, and waiting time, and its approximation by the Kingman formula. Let me show you a quick and easy dice game where we simulate a supermarket checkout to let participants experience the effect of utilization, fluctuation, and the (worse) combined effect of both.

Taiichi Ohno’s Chalk Circle

One of the famous teaching methods by Taiichi Ohno is the chalk circle. The method itself is simple. A circle is drawn on the shop floor near a point of interest. A disciple is put in the circle and told not to leave it until he is picked up again by the teacher.

One of the famous teaching methods by Taiichi Ohno is the chalk circle. The method itself is simple. A circle is drawn on the shop floor near a point of interest. A disciple is put in the circle and told not to leave it until he is picked up again by the teacher.

In this post I will explain a bit about the chalk circle, how to use it for teaching, and how to use it for yourself.