FIFO (first in, first out) is one of the simplest and most basic ideas in manufacturing, and yields significant benefits. It is so simple that I don’t even want to call it a tool, since it is one of the fundamentals in manufacturing (and many other areas). In this post I want to take a closer look at the power of this most fundamental approach to material flow.

FIFO (first in, first out) is one of the simplest and most basic ideas in manufacturing, and yields significant benefits. It is so simple that I don’t even want to call it a tool, since it is one of the fundamentals in manufacturing (and many other areas). In this post I want to take a closer look at the power of this most fundamental approach to material flow.

FiFo

Maintaining Weak FIFO in Parallel FIFO Lanes

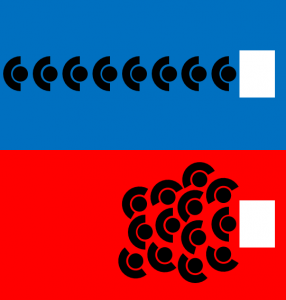

Sometimes you would like to put more material in a single FIFO lane than the space you have available. In this case you would have to use a combination of two or more parallel FIFO lanes. In my last post I described how to maintain a strict FIFO sequence in parallel lanes. This post looks at an easier but less accurate method.

Sometimes you would like to put more material in a single FIFO lane than the space you have available. In this case you would have to use a combination of two or more parallel FIFO lanes. In my last post I described how to maintain a strict FIFO sequence in parallel lanes. This post looks at an easier but less accurate method.

Maintaining Strong FIFO in Parallel FIFO Lanes

Production Sequences: FCFS, EDD, and Others

Delivery Sequences: FIFO, LIFO, and Others

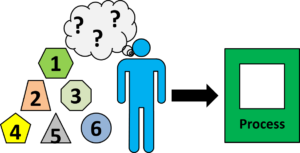

Sometimes, when you need a part or product from your inventory, you may have more than one item in stock. Which one do you pick? In this blog post I want to present a few strategies for choosing which item to take. The most famous one is FIFO, but there are more options available. In my next post I will present similar strategies if you need to start production before the item becomes available.

Sometimes, when you need a part or product from your inventory, you may have more than one item in stock. Which one do you pick? In this blog post I want to present a few strategies for choosing which item to take. The most famous one is FIFO, but there are more options available. In my next post I will present similar strategies if you need to start production before the item becomes available.

Top Five Cases When NOT to Use a FiFo

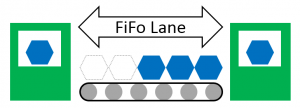

Standard wisdom for creating a good material flow is to use FiFo lanes (First in, First out). In other words, the first part that goes into the line should also be the first part that comes back out. As such, FiFo lanes and its big brother, Supermarket, are essential for any lean material flow. However, some rules of wisdom can be bent and others can be broken. Here are the top five cases when NOT to use a FiFo lane.

Standard wisdom for creating a good material flow is to use FiFo lanes (First in, First out). In other words, the first part that goes into the line should also be the first part that comes back out. As such, FiFo lanes and its big brother, Supermarket, are essential for any lean material flow. However, some rules of wisdom can be bent and others can be broken. Here are the top five cases when NOT to use a FiFo lane.

The FiFo Calculator – Determining the Size of your Buffers

In my previous post, I discussed how to Determine the Size of Your FiFo Lane – The FiFo Formula. My preferred method is still an expert estimate. However, if you are interested in the math, here is a small JavaScript calculator that estimates a FiFo size for two processes.

In my previous post, I discussed how to Determine the Size of Your FiFo Lane – The FiFo Formula. My preferred method is still an expert estimate. However, if you are interested in the math, here is a small JavaScript calculator that estimates a FiFo size for two processes.

Determining the Size of Your FiFo Lane – The FiFo Formula

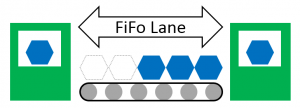

FiFo lanes are an important tool to establish a pull system. They are often combined with kanban. However, while there is a lot of information on how to calculate the number of kanban (the Kanban Formula), there is very little information available on how large a FiFo should be. In my last post I talked about why we need FiFo lanes. In this post I want to discuss how large a FiFo should be.