This is the third post in my series on how Fendt handles its rather large variability. As mentioned before, all of their tractors—eleven different models with countless variants—come from the same assembly line in Marktoberdorf. This includes small tractors that are just barely one meter wide and huge ones as you see here on the left. Imagine assembling motor bikes, cars, and trucks on the same assembly line, and you are getting close to the variability that Fendt has to deal with. Overall, this makes Fendt in my view one of the leading plants in the world in handling variability.

This is the third post in my series on how Fendt handles its rather large variability. As mentioned before, all of their tractors—eleven different models with countless variants—come from the same assembly line in Marktoberdorf. This includes small tractors that are just barely one meter wide and huge ones as you see here on the left. Imagine assembling motor bikes, cars, and trucks on the same assembly line, and you are getting close to the variability that Fendt has to deal with. Overall, this makes Fendt in my view one of the leading plants in the world in handling variability.

Efficiency

Luxury Car Assembly at Audi and Daimler

How to Pace Your Assembly Line

An assembly line is a manufacturing process in which a product is built in a step-by-step sequence. One of many decisions when installing an assembly line has to do with its pacing. When should you use a pulsed line? When a continuously moving line? And when is an unstructured timing best? This post will look at the pros and cons of these options.

An assembly line is a manufacturing process in which a product is built in a step-by-step sequence. One of many decisions when installing an assembly line has to do with its pacing. When should you use a pulsed line? When a continuously moving line? And when is an unstructured timing best? This post will look at the pros and cons of these options.

Keep Calm and Stop the Line—Part 2

In manufacturing, a common sentiment is that the line (or generally the process) must run. There is some truth to that, but—counterintuitively—for a system to run well you need to know when to stop it too. This is my second post in a series giving you an overview on when it may be better to stop the line rather than keeping it running (and making everything worse). Keep on reading!

In manufacturing, a common sentiment is that the line (or generally the process) must run. There is some truth to that, but—counterintuitively—for a system to run well you need to know when to stop it too. This is my second post in a series giving you an overview on when it may be better to stop the line rather than keeping it running (and making everything worse). Keep on reading!

Keep Calm and Stop the Line—Part 1

In industry, I often find the view that machines must run. The reasons given for this are that the machines were expensive investments, labor cost will accumulate, and the customer is waiting for products, hence the line must run. There is definitely some truth in this. However, the conclusion that the line must not stop is completely wrong. On the contrary, for the line (or the process in general) to run well, you MUST stop the line in certain circumstances. In this and the next post I would like to look in more detail at when you, rather than pressing forward with production (or rather, your operators), should stop the line. Let me explain.

In industry, I often find the view that machines must run. The reasons given for this are that the machines were expensive investments, labor cost will accumulate, and the customer is waiting for products, hence the line must run. There is definitely some truth in this. However, the conclusion that the line must not stop is completely wrong. On the contrary, for the line (or the process in general) to run well, you MUST stop the line in certain circumstances. In this and the next post I would like to look in more detail at when you, rather than pressing forward with production (or rather, your operators), should stop the line. Let me explain.

Ramp-Up and Ramp-Down of Production

In my last post I looked at the preparations for a proper ramp-up or start of a machine or process. This post is the second part where you actually press the button and start the machine. I will also discuss the ramp-down procedures, as well as a SMED-like approach to improve the ramp down and up again process.

In my last post I looked at the preparations for a proper ramp-up or start of a machine or process. This post is the second part where you actually press the button and start the machine. I will also discuss the ramp-down procedures, as well as a SMED-like approach to improve the ramp down and up again process.

Preparation for Ramp Up and Down of Production

Some factories work around the clock. But more commonly, factories ramp up at the beginning of the week, workday, or shift and then ramp down at the end. I often have the feeling that this is a somewhat neglected topic despite its influence on safety, quality, and efficiency. Hence I would like to take a closer look at the ramp-up and ramp-down procedures in industry, and how to optimize them. This first post will look at how to prepare a ramp-up before actually flicking the switch of the process.

Some factories work around the clock. But more commonly, factories ramp up at the beginning of the week, workday, or shift and then ramp down at the end. I often have the feeling that this is a somewhat neglected topic despite its influence on safety, quality, and efficiency. Hence I would like to take a closer look at the ramp-up and ramp-down procedures in industry, and how to optimize them. This first post will look at how to prepare a ramp-up before actually flicking the switch of the process.

Why FIFO: The Benefits of First In, First Out

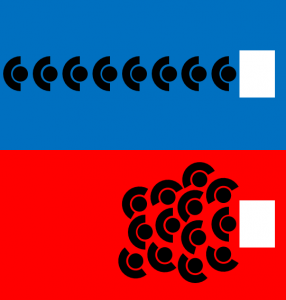

FIFO (first in, first out) is one of the simplest and most basic ideas in manufacturing, and yields significant benefits. It is so simple that I don’t even want to call it a tool, since it is one of the fundamentals in manufacturing (and many other areas). In this post I want to take a closer look at the power of this most fundamental approach to material flow.

FIFO (first in, first out) is one of the simplest and most basic ideas in manufacturing, and yields significant benefits. It is so simple that I don’t even want to call it a tool, since it is one of the fundamentals in manufacturing (and many other areas). In this post I want to take a closer look at the power of this most fundamental approach to material flow.