Dashboards, in their many forms, are essential to track the performance of a production system. In this post I will talk more about the Toyota shop floor dashboard. A lot of the information is from Toyota in Japan, but the images are from Toyota UK. Keep in mind that the dashboards are not a rigid standard and there may be differences in how they are implemented in the different plants. For one thing, in Japan they are in Japanese, and in the UK in English, but there are also differences within the KPI itself. Let me tell you more in this short series on the Toyota KPI dashboards…

Dashboards, in their many forms, are essential to track the performance of a production system. In this post I will talk more about the Toyota shop floor dashboard. A lot of the information is from Toyota in Japan, but the images are from Toyota UK. Keep in mind that the dashboards are not a rigid standard and there may be differences in how they are implemented in the different plants. For one thing, in Japan they are in Japanese, and in the UK in English, but there are also differences within the KPI itself. Let me tell you more in this short series on the Toyota KPI dashboards…

Toyota

On the Team Structure at Toyota

Toyota is (among other things) famous for its team structure on the front line. They have a quite low ratio of team members to supervisors, and I believe that is part of their success. Whereas many Western companies overstuff their hierarchy, at Toyota supervisors actually have the time to help their people and to also improve the operations. Let me dig deeper into that. This blog post was inspired by the new book by Baudin and Netland, Introduction to Manufacturing.

Toyota is (among other things) famous for its team structure on the front line. They have a quite low ratio of team members to supervisors, and I believe that is part of their success. Whereas many Western companies overstuff their hierarchy, at Toyota supervisors actually have the time to help their people and to also improve the operations. Let me dig deeper into that. This blog post was inspired by the new book by Baudin and Netland, Introduction to Manufacturing.

Toyota’s New Type of Flexible Assembly Lines—Takaoka Line #2

Flexible assembly lines are well known at Toyota – except that there are two types of “flexible assembly lines.” The well-known one is making multiple different models on the same line. But Toyota has developed a new type of flexible assembly line, where the entire layout of the assembly line can be changed quickly and easily. Confusingly, this is also called a flexible assembly line, although Toyota itself does not even have a name for it (different from the West, Toyota focuses more on doing something, while the West often puts the most effort into a catchy name). Their pilot line is in the Takaoka plant. Let me show you.

Flexible assembly lines are well known at Toyota – except that there are two types of “flexible assembly lines.” The well-known one is making multiple different models on the same line. But Toyota has developed a new type of flexible assembly line, where the entire layout of the assembly line can be changed quickly and easily. Confusingly, this is also called a flexible assembly line, although Toyota itself does not even have a name for it (different from the West, Toyota focuses more on doing something, while the West often puts the most effort into a catchy name). Their pilot line is in the Takaoka plant. Let me show you.

Toyota’s Six Rules for Kanban

The kanban system is the most famous way to establish a pull system. As part of their guidelines for kanban, Toyota has established Six Rules for Kanban. They can be found, for example, in the 1973 Toyota Production System Handbook. This blog post describes these six rules, based on the Toyota handbook. While these rules are all true, they are in themselves not sufficient to establish a kanban pull production. Nevertheless, this post will show you these six rules.

The kanban system is the most famous way to establish a pull system. As part of their guidelines for kanban, Toyota has established Six Rules for Kanban. They can be found, for example, in the 1973 Toyota Production System Handbook. This blog post describes these six rules, based on the Toyota handbook. While these rules are all true, they are in themselves not sufficient to establish a kanban pull production. Nevertheless, this post will show you these six rules.

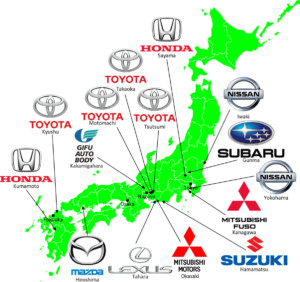

The Grand Tour of Japanese Automotive – Overview and Toyota

During Winter 2017–2018, I spent five months in Japan. As part of this visit, I was able to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive Plants.

During Winter 2017–2018, I spent five months in Japan. As part of this visit, I was able to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive Plants.

This was extremely insightful, and I learned a lot about the differences between the Japanese car makers. Let me give you an overview and some details on Toyota plants before firing off a series of blog posts on the different Japanese automotive companies.

Continued Evolution of the Toyota Assembly Line

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

The Toyota Employee Evaluation System

Anatomy of the Toyota Kanban

While Toyota did not invent the pull system, they did invent kanban, the genius idea of using cards of paper (and later other forms of information) to create a pull system for mass-produced goods. I recently was able to take pictures of Toyota kanbans, and would like to show and explain them to you.

While Toyota did not invent the pull system, they did invent kanban, the genius idea of using cards of paper (and later other forms of information) to create a pull system for mass-produced goods. I recently was able to take pictures of Toyota kanbans, and would like to show and explain them to you.