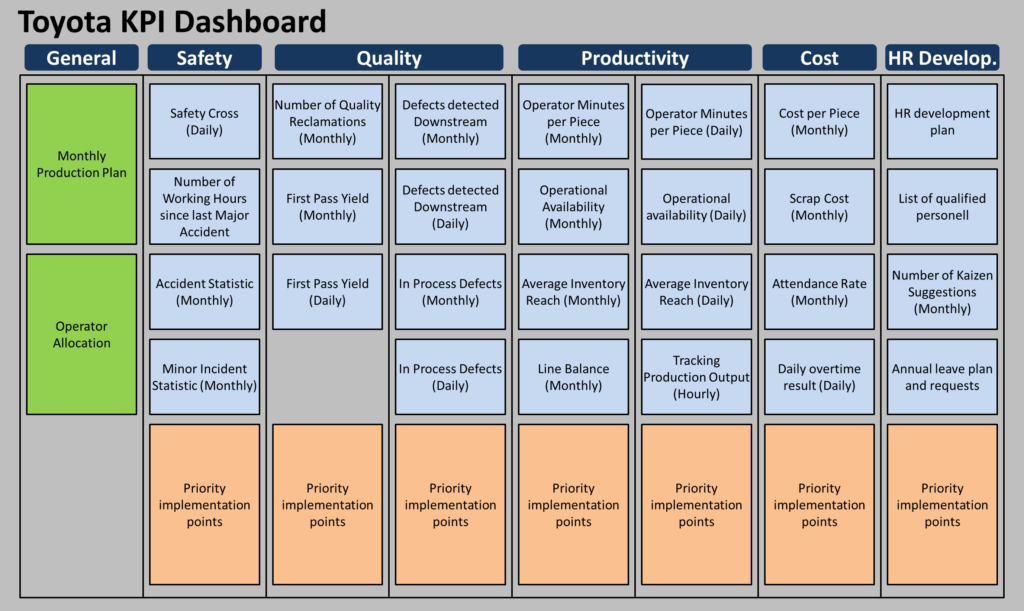

With the KPI groups safety, quality, productivity, and cost, this series on the Toyota KPI dashboard has covered the main topics. However, there is more. Not always but often you can also find a section on human resources (HR) development. Yet, these are usually not KPI, but more organizational topics that may be part of the daily shop floor meeting. Below are some examples of how this section could look, although this may vary quite a bit among different Toyota plants. Let’s have a look:

With the KPI groups safety, quality, productivity, and cost, this series on the Toyota KPI dashboard has covered the main topics. However, there is more. Not always but often you can also find a section on human resources (HR) development. Yet, these are usually not KPI, but more organizational topics that may be part of the daily shop floor meeting. Below are some examples of how this section could look, although this may vary quite a bit among different Toyota plants. Let’s have a look:

Introduction

A company makes or breaks with its people. Having the right kind of people, training them, and treating them well is important for the success of a company. You need to show respect for people to have good relations with your workforce and hence have a good workforce. So, not always but often there is a HR section on the dashboard. However, these are usually not KPI, but more organizational topics like the plan for who is on leave and when, as well as the HR development plan to show who should get which trainings when. Even the number of improvement (kaizen) suggestions is not necessarily a KPI, as it may or may not have an actual goal.

HR Development Plan

This section can include an HR development plan—for example, which employee is scheduled or assigned for which trainings. Keep in mind that Toyota spends much more time on training and qualification (both on the shop floor as well as off the shop floor) than most other companies.

It may also include generic information on the requirements for promotion. Below is such an example from the Toyota UK plant in Deeside and their “Member Development Map—Manufacturing Team Member up to Section Manager.”

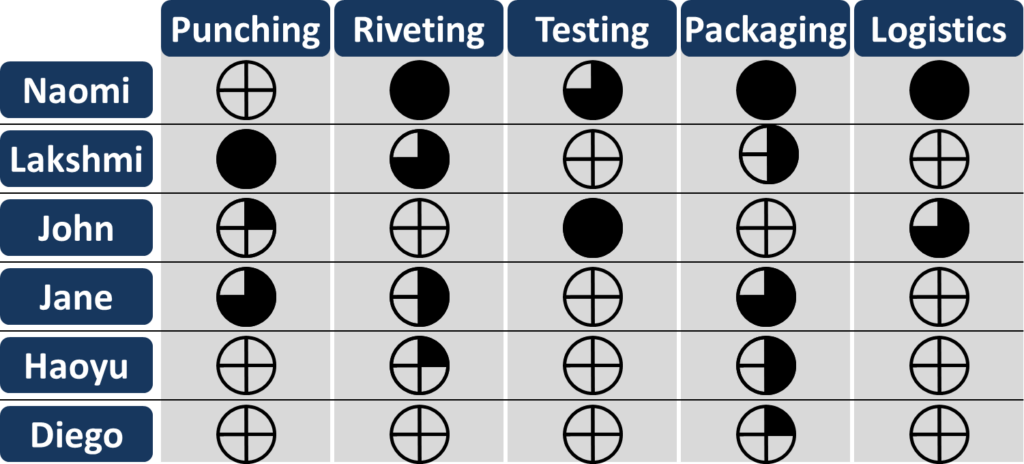

List of Qualified Personnel

The list of qualified people can also be included in this section of the dashboard. This could look like a qualification matrix (also skill matrix, competence matrix, or Q-matrix), showing which employee is qualified in which tasks.

Number of Kaizen Suggestions

At Toyota they also often track the number of improvement ideas that are generated. Below is how such a sheet could look, albeit, honesty, this is my own idea how it could be, and I don’t have the actual example from Toyota. I am not even sure if this includes a target or not. I am a bit wary of including targets, as this is a number that can easily be manipulated.

Here’s a photo from the Toyota UK Deeside plant with a box for improvement ideas, including a filled-out idea. Please note that there is a significant difference in the number of ideas generated. While in the USA, there is a measly 0.16 ideas generated by employee and year, in Japan it is a whopping 18.5 ideas per employee and year (source: Corporate Creativity, by Robinson and Stern, 1998, ISBN 978-1576750490). Through my own grapevine I have heard that at Toyota, it is around 50 ideas per employee and year, meaning one per employee and week. Womack mentions 61.6 suggestions at Toyota per employee and year, whereas in Europe there were only 0.4 suggestions per employee and year.

Here’s a photo from the Toyota UK Deeside plant with a box for improvement ideas, including a filled-out idea. Please note that there is a significant difference in the number of ideas generated. While in the USA, there is a measly 0.16 ideas generated by employee and year, in Japan it is a whopping 18.5 ideas per employee and year (source: Corporate Creativity, by Robinson and Stern, 1998, ISBN 978-1576750490). Through my own grapevine I have heard that at Toyota, it is around 50 ideas per employee and year, meaning one per employee and week. Womack mentions 61.6 suggestions at Toyota per employee and year, whereas in Europe there were only 0.4 suggestions per employee and year.

According to Robinson and Stern, the adoption rate in Japan is 90%, significantly higher than the 38% in the USA, and 74% of employees generate ideas in Japan, whereas only 11% do so in the USA. The USA, however, pays better for ideas, with in average USD $458 per idea, where in Japan it is a measly USD $3.88. Money clearly is NOT the motivator for idea generation. Yet, due the significantly larger number of ideas and their adoption, the net savings in Japan is USD $3250 per employee and year, almost ten times as much as in the USA with only USD $334 of savings. The reason for these differences are worth their own blog post, but in my opinion one reason is that Toyota actually has the manpower to implement even smaller ideas, whereas in the Western world all such maintenance and support people have long since been axed to the minimum.

Annual Leave Plan and Requests

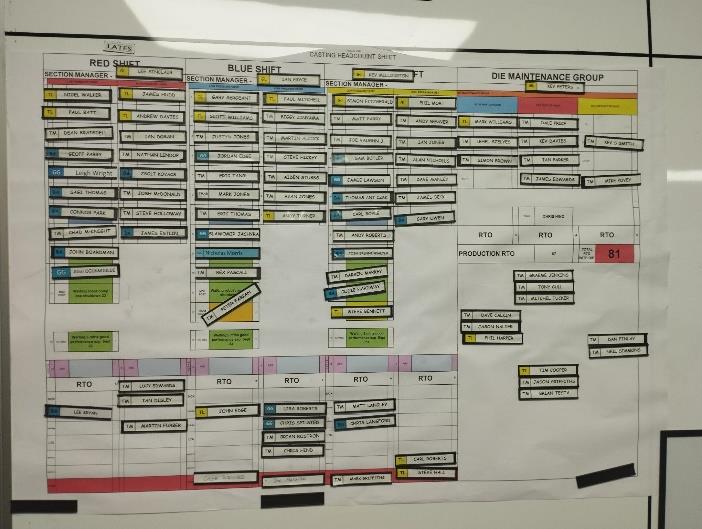

This section of the dashboard can also include annual leave plans and requests for leave. However, these are also often found in the worker assignment section (see next post). Below are two examples from the Toyota UK Deeside plant with different shift assignment boards, one using magnets on a metal board, the other one being digital.

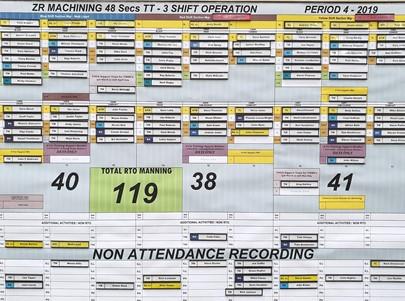

Another Version of the HR Dashboard: A3s

Again, there is no fixed standard at Toyota. Below is a dashboard from the Toyota UK Deeside engine plant, labeled H.R.D. (for Human Resources Development), but it is all a list of A3 sheets for problem-solving. The different colors (red, blue, yellow) represent different shifts. The columns are the different section in the engine casting department.

In summary, this feels a bit like odds and ends, and may look quite different between different Toyota plants. As always, adapt this for your needs and don’t just copy whatever Toyota does. Not even Toyota simply copies what (another plant at) Toyota does. Now, go out, learn from Toyota, but do not copy it, and organize your industry!

PS: Many thanks to Mikako Lenquist from C2U in Sweden for organizing the Lean Leadership System in Japan 2023, where former Toyota factory manager and director in charge of TPS promotion Akinori Hyodo shared his wisdom. Most of the data in this post series I learned from this tour.

Additional thanks to the team from the Toyota Lean Management Centre at the Toyota UK Deeside engine plant in Wales, where I participated in their 5-day course. This course gave us a lot of access to the Toyota shop floor, and we spent hours on the shop floor looking at processes. In my view, this the only generally accessible course by Toyota that gives such a level of shop floor involvement (albeit they want to open another center at the UK Burnaston final assembly plant).

Both the C2U Lean Leadership System course as well as the Toyota Lean Management Centre 5-day course are highly recommended!

Outstanding series of posts.

Hello Christoph,

could you please upload a more detailed “HR Development Plan” or explain the logic and elements within it? I would like to understand the requirements that Toyota has for its future leaders.

Best regards,

Alex

Hi Alexander, I don’t have a high resolution picture of the plan, sorry. It is basically a road map from new employee to plant manager, including the requirements for promotion.