The Copacabana is a very nice beach in Rio de Janeiro. Spelled slightly differently, COBACABANA is a production control approach. Here, COBACABANA stands for Control of Balance by Card Based Navigation (sometimes also abbreviated to COBA). It is an approach to manage a job-shop workload of custom orders using paper cards. A lot of paper cards, in fact, which also makes the method a bit complex, and I am doubtful if this method is practical. Let me show you how it works.

The Copacabana is a very nice beach in Rio de Janeiro. Spelled slightly differently, COBACABANA is a production control approach. Here, COBACABANA stands for Control of Balance by Card Based Navigation (sometimes also abbreviated to COBA). It is an approach to manage a job-shop workload of custom orders using paper cards. A lot of paper cards, in fact, which also makes the method a bit complex, and I am doubtful if this method is practical. Let me show you how it works.

Introduction

COBACABANA was developed by Martin Land and improved by Matthias Thürer (Side note: I do like his book on Card-Based Control Systems quite a bit).

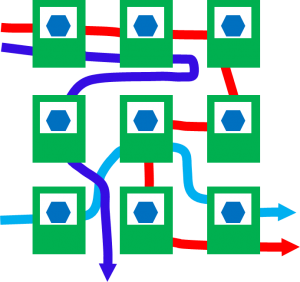

COBACABANA aims to help with the management of job shops, especially the task of keeping your processes busy without overloading one or idling the other. This is a daunting task that many have tried but few succeeded at. Furthermore, it does so using only paper cards. As a result, the method is rather complex.

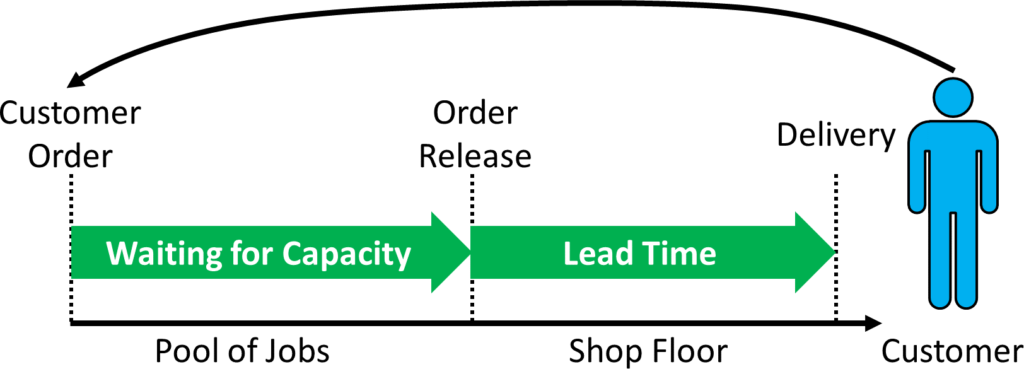

COBACABANA breaks the flow of a customer order into two main parts. When the customer order arrives (or is accepted), it first goes into a pool of open jobs waiting for production capacity. Once the order is released for production, the job travels through the shop floor, which is the second part.

A push system would simply release these open jobs into the factory. A pull system, however, controls and limits the amount of work on the shop floor. COBACABANA is a pull system, as it releases work into the shop floor only if capacity is available.

The Release from the Pool of Open Orders

A customer orders an item. This item would need to be processed at different machines within the system. The time needed for this order is estimated for every machine. Assume an order of parts would need six hours of milling, eight hours of hardening, and four hours of grinding. This order first goes into the pool of open orders before being released for production.

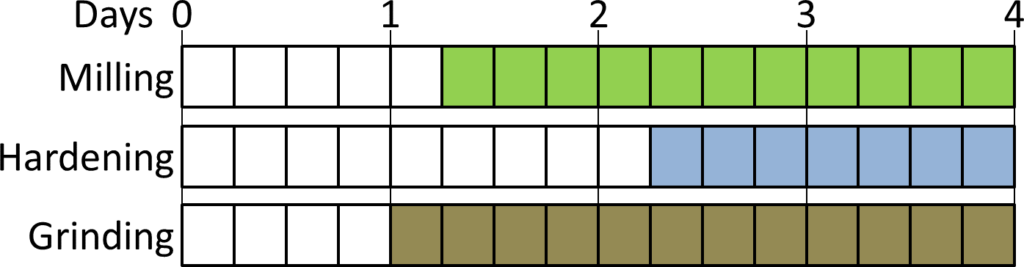

To keep an overview of the workload, each process has a set of acceptance cards representing a certain workload that is already in the pool for this order. This is shown below. In this example, each card represents two hours of work. There are already open orders in the pool equivalent to ten hours of milling, eighteen hours of hardening, and eight hours of grinding. For easier visualization, each process has its own color.

With the new order, we need another six hours of milling, eight hours of hardening, and four hours of grinding. Hence we remove three cards (six hours) from milling, four cards (eight hours) from hardening, and two cards (four hours) from grinding. These nine cards are attached to the open order in the pool.

Afterwards, the acceptance cards stack would look like the image below. Hence, the person managing the stack always has a good overview of the work that is already committed to the customer but not yet released.

The Shop Floor Release Process

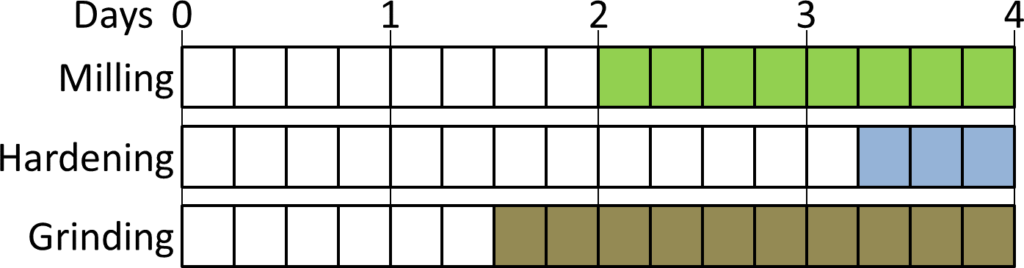

A similar method is used for the release of the orders. The backbone of every pull system is a limit on the work in the system. Most pull systems merely count the number of jobs, but COBACABANA actually measures the workload. The approach is similar to the pool of open orders above, except that there is a fixed number of cards. These cards are called Release Cards. The total number of cards represents the maximum amount of work you want to put into the system at the same time.

An example is shown below. Each card represents a certain amount of work. For simplicity’s sake, I also assumed each card is the equivalent of two hours’ worth of work (although the original author suggested 1% of the desired maximum workload – in which case you would end up with one hundred cards per station).

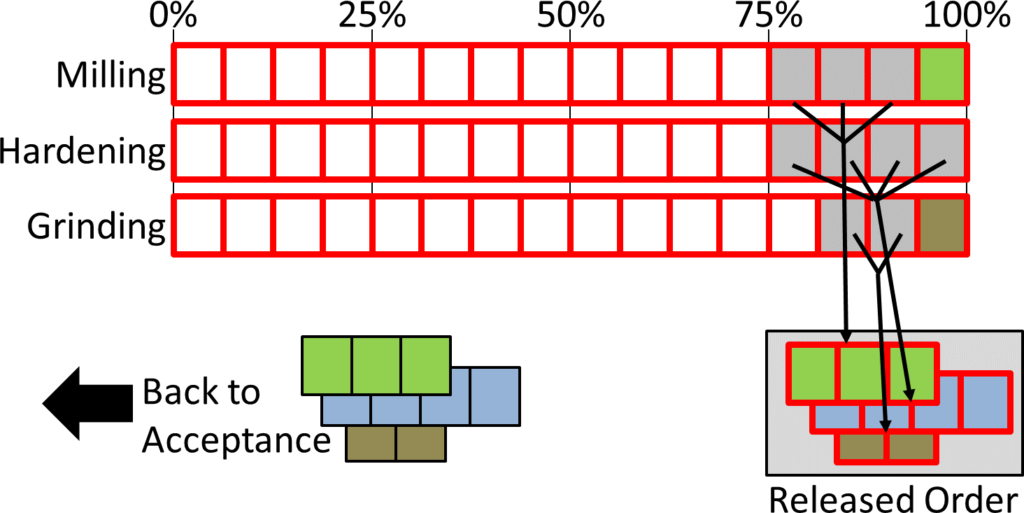

When releasing a job from the pool to the shop floor, the acceptance cards go back to the pool. The release cards are removed from the release stack and attached to the open order. You must have enough release cards to release the order; otherwise the order cannot be released and has to wait in the acceptance pool. The jobs are released according to their planned release date, with the hope that the most urgent job will be the next one in line for the shop floor.

In our example, we just barely had enough cards for hardening to release the order to the shop floor. The release stack afterwards is shown in the image below. Hence, the order release always has a good overview of the current workload of each station (although again at the cost of quite a lot of cards).

Once the job is completed, the release cards go back to the release stack to be available for the next jobs to be released.

Some Tweaks

Since the method was originally presented by Land in 2009, the method has been adjusted a bit. Quite a bit actually. While it does have the same name, consider it COBACABANA 2.0 (or even 3.0).

Literature describes a use to estimate a due date based on the data from the release pool under the assumption that the lead time on the shop floor is relatively stable (although I am a bit doubtful of that).

To avoid the inflationary large number of cards for different jobs, Thürer recommends instead using only a single custom card per job and workstation whose size (i.e., length) represents the workload for this station. This significantly cuts down on the number of cards, but requires the cutting of custom-sized cards for every job. Since this update to the method, they have figured out that cutting cards is cumbersome, and now recommend cards in different standard sizes. Here it seems three sizes (small, medium, large) is good enough in terms of accuracy. You simply pick the card whose size matches your workload best.

To avoid the inflationary large number of cards for different jobs, Thürer recommends instead using only a single custom card per job and workstation whose size (i.e., length) represents the workload for this station. This significantly cuts down on the number of cards, but requires the cutting of custom-sized cards for every job. Since this update to the method, they have figured out that cutting cards is cumbersome, and now recommend cards in different standard sizes. Here it seems three sizes (small, medium, large) is good enough in terms of accuracy. You simply pick the card whose size matches your workload best.

Additional cards are added. A single pool card per open order in the pool is created. The acceptance cards from above are given to the salesperson. The height of the stack of acceptance cards at the salesperson gives him an estimate on how long the delay of orders in the pool will be. The pool card stays with the open order.

On the shop-floor side, an operation card was added to the release cards. The release card is cut to the correct size and stays with the planner. The height of the stack of release cards represents the workload. New jobs are released only if there is enough space in the stack for them. The operation card travels with the job to the processes. After completion, the operation card returns to the planner, who then also releases the release card back into the stack.

Review

Overall, the approach looks a bit theoretical. I have the feeling that there is not yet any beneficial real-world application, and that not all kinks and issues of the method have yet been fully debugged. There is definitely ongoing work (e.g., workload representation changing from many single cards of same size to custom cut card size to different standard card sizes…)

Overall, the approach looks a bit theoretical. I have the feeling that there is not yet any beneficial real-world application, and that not all kinks and issues of the method have yet been fully debugged. There is definitely ongoing work (e.g., workload representation changing from many single cards of same size to custom cut card size to different standard card sizes…)

The number of cards (or the cutting of custom card sizes) and its complexity is an issue for me, albeit in my opinion there simply are no good AND easy solutions for job shop control.

I do like the focus on a purely paper-based system without any ERP system that most people don’t really understand. In that aspect, COBACABANA is quite unique. It is the only purely paper-based method that manages the workload of a job shop.

In any case, there seems to be an ongoing stream of publications on the topic, mostly by Thürer, and maybe in the future there will be more updates and changes to make the system easier to use. In the meantime go out, use kanban, CONWIP, or POLCA, and organize your industry!

Selected Sources

- Thürer, Matthias. Card-Based Control Systems for a Lean Work Design: The Fundamentals of Kanban, ConWIP, POLCA, and COBACABANA. Productivity Press, 2017.

- Land, Martin. “Cobacabana (Control of Balance by Card-Based Navigation): A Card-Based System for Job Shop Control.” International Journal of Production Economics 117 (2009): 97–103.

- Thürer, Matthias, Mark Stevenson, and Charles W. Protzman. “COBACABANA (Control of Balance by Card Based Navigation): An Alternative to Kanban in the Pure Flow Shop?” International Journal of Production Economics 166 (August 1, 2015): 143–51. https://linkinghub.elsevier.com/retrieve/pii/S0925527315001620.

This system is actually similar to what I came up with to schedule our prototype manufacturing cell. I have certain resources available (mill, lathe, etc.) and a limited amount of manpower to run them. In theory i can estimate each job and schedule to shop based on capacity. But in practice it is extremely difficult largely due to the inconsistent human performances. Setup time, new product development, decision making, etc. plays a large role. Good read. Thanks.

Hi Christoph,

Thank you for presenting a clear and understandable explanation of this system!

I really like the system, the method and the principles are extremely simple and easy to understand, yet managing the card system can be very daunting in practicality, if you have many machines and many part numbers.

That being said, the management part can always be kaizened to make it more manageable, but the real question is, would you make your calculations based on the assumption that every machine and operator run at 100% availability all the time?

I think the first thing I would do for the cards is to base them on cycle times rather than process times, i.e. if a certain machine runs for 1 hour, is down for 50% of the time every week on average, due to breakdown, then I would make the cards 2 hours long instead (I am oversimplifying a bit but something along those lines),

Of cource the goal would be to reduce the breakdown time over time.

The question is, would these two countermeasures (improve the management of the system and base the cards on cycle times) increase your confidence in the tool?

Hi Emanuel, there is definitely improvement potential. It is one of my philosophies in lean that anything can be improved. Yet, I prefer CONWIP or POLCA over COBACABANA, as the latter one lacks a proof of concept though a real factory using this system.

I have personally experienced with implementations of dozens MTO (Generic) pull systems. As an idea, COPACABANA is a very cool solution that reminds me of the original Toyota kanban system, where the car that entered the production line consisted of a set of withdarwals kanban cards, which at certain stages of production took materials from supermarkets. Unfortunately, Copacabana (I assume it is one family from WLD/ DEWIP) has two important weakness for me: it is still a central system, where entry decisions are made at the central planning level (before shop floor). In the case of many processes, at lower level of value stream, there is high chance of blocking the system, because of the production capacity variability. And in the real world we have lot of variability.

The second disadvantage is the need to build physical cards for indirect WIP. And, for example, in POLCA/ COWNIP we only have cards for direct WIP. In a developed system with many routings and workstations, this becomes impractical.

Personally, the POLCA system works better for me, because decision-making process is transferred to work centers (at the level of shop floor) that respond quickly to variability at every level of the value stream. Of course, POLCA also has its disadvantages, and there is no perfect system.

POLCA is used to execution the production plan. COMAPACANA is a more advanced planning system. It would be ideal to combine these two solutions where:

POLCA remains as the control system, and when POLCA begins to pull the plan, entry is on COPACABANA (or more precisely WLC) principles. This solution works best for me personally.