In the last post I described how to balance a line using pen and paper. This description was a basic, straightforward approach. In this post, I will enhance it with a few tips and tricks for balancing a line. Also, I will briefly describe how to balance a line using computers and then tell you why I much prefer the paper version. If you have not yet done so, please check out my earlier posts on line balancing.

In the last post I described how to balance a line using pen and paper. This description was a basic, straightforward approach. In this post, I will enhance it with a few tips and tricks for balancing a line. Also, I will briefly describe how to balance a line using computers and then tell you why I much prefer the paper version. If you have not yet done so, please check out my earlier posts on line balancing.

A Few Pro-Tips on Line Balancing

The Target Cycle Time Is Not a Hard Target

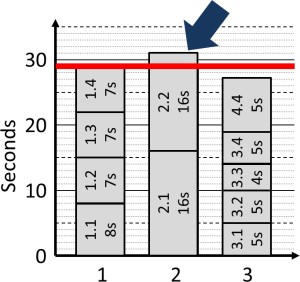

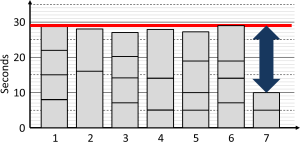

In the last post, we added a target line on the chart for the line balancing. This is usually the target cycle time. Please be aware that this target line is not a hard limit!

We calculated the line by combining the customer demand with the OEE, and then stacked the duration of the tasks underneath. These numbers are probably not precise. The OEE, especially, often has lots of ambiguity, and the customer demand is also somewhat uncertain. The duration of the tasks is usually most precise – if you have a system that you can already measure. In any case, the numbers involved in fitting the task durations to the target are usually rather imprecise.

That means you have wiggle room. If you stack the task durations up, you may have a situation where you only slightly exceed the target. That is probably OK. Based on your uncertainties, a small excess duration may turn out to be no excess at all.

If it turns out to be a problem, you still have options. You could put in some more effort and reduce the duration of one or more of the tasks that exceed your target. In fact, adding a tiny bit of pressure for improvement often helps with the improvement.

Finally, in the unlikely event that it is indeed a problem, and you cannot fix it by improving, you may have to go into overtime to meet the customer demand.

While there is a bit of risk involved, it may be much easier to take the risk than to rearrange the tasks differently and end up with a very wasteful structure where there are lots of gaps and idle waiting time for workers and machines.

Overall, if you exceed the target, there may not be a problem in the first place, or you can optimize the durations, or you can do some overtime. All of these may be easier than an alternative rearrangement, so you have to decide which path is the easiest for your situation.

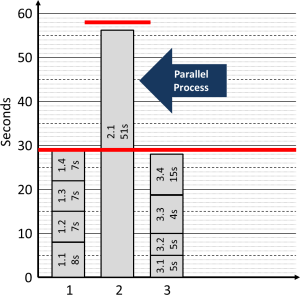

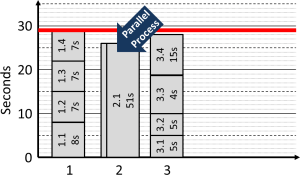

Parallel Processes if Task Time Exceeds Target Time

Please keep in mind that while a small excess may be acceptable, a larger excess may be more problematic. When your cycle time exceeds your takt time, you do have a problem. It may be necessary for you to duplicate an especially slow process so that the combined speed of the two processes meets the target.

Please do so. If you duplicate the process in parallel, your target line for an individual process doubles – or your combined cycle time divides by two. Similarly, if you triple or quadruple the processes, so does the target, or alternatively the cycle time reduces to a third or a fourth. Either way works. In general, if you have n parallel processes with identical speeds, the target line multiplies by n, or alternatively the joint cycle time divides by n. It does become more tricky if the processes are not identical (i.e., a fast one and a slow one). (See Pitfalls of Takt Times.)

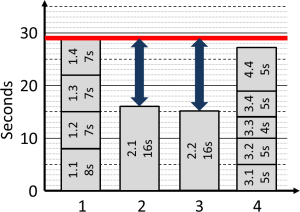

Pool Leftover Time at the End

In all likelihood, you will have a few tasks left at the end that are not enough for a full cycle. For machines, that is not a problem. For operators, however, it is an issue. In lean manufacturing, it is considered impolite to let people wait. That is true. Since the last process has lots of waiting time, some shop floor managers distribute the tasks evenly so that everybody has a similar waiting time.

Don’t do it!

While the goal of having nobody wait is valid, in this case it may be the smaller problem. If everybody has additional time, either you produce more than needed (bad), have a group that needs less work hours (acceptable depending on your situation), or have a group that can slack off and work slower (really bad). Working slower than a regular speed may be boring, increase quality problems, and damage worker morale.

Overall, the wisdom at Toyota is to (usually) have one process or worker with less tasks than the others. Preferably, this is also the last process of the line. This has a few advantages.

- The worker has a longer waiting time. Depending on the situation, there may be additional tasks that can be done during this time (e.g., restock line inventory, remove boxes, etc.).

- The waiting time is more obvious, and hence there is more mental pressure to optimize the tasks and reduce their durations so that eventually the line can work with one station less. Hence, it helps with optimizing the processes.

- While we wish that all our workers are young, fit, and able, we do have workers that are older, less able, or temporarily or permanently impaired. This could be anything from back pain and pregnancy. We do have the duty to also provide these people with work, and such a slower task may just be the right thing for temporarily or permanently impaired workers.

Balancing the Line Using a Computer

In my last post, Line Balancing Part 5 – Balancing Using Paper, I explained how to do balancing with paper. Of course, this can also be done using computers. Some programs let you play with the sequence and do the calculation of the total duration for you. Others even do the optimization for you. I would avoid having a computer do the optimization of the tasks. For one, it is probably quite an effort to add all the necessary sequence conditions in the system. Additionally, I think humans are still better at understanding the complexity of the line balancing, and where you may have wiggle room and where you may not. Hence, let people make the decision on the sequence, and have computer only help.

I much prefer line balancing in a group and on paper. However, sometimes when I do line balancing on my own, I use Excel simply because I know Excel very well. For the amount of line balancing I do, it is for me not worth the effort to learn a new software. In Excel, it is just quick and dirty, nothing fancy.

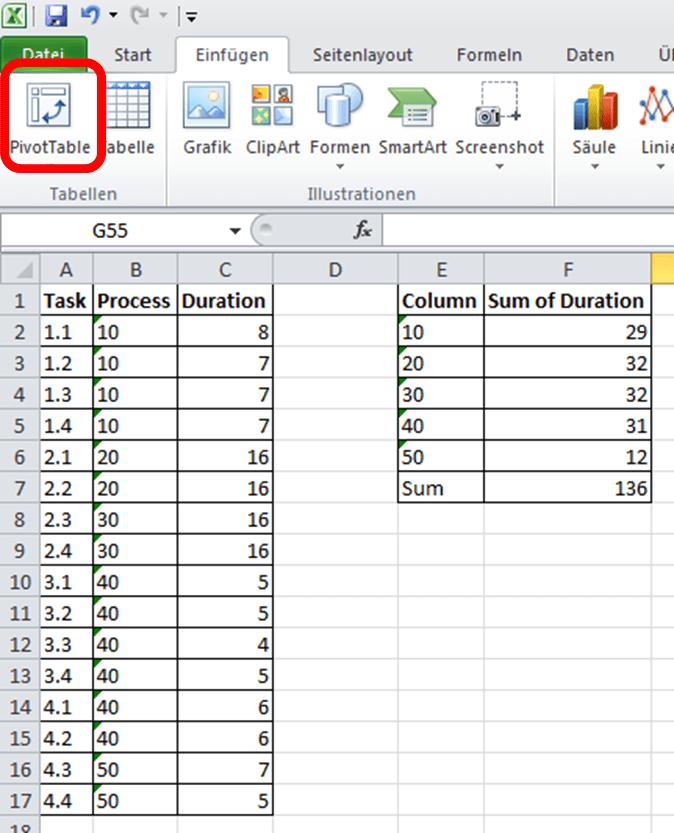

I make a simple table with a column for the processes, their sequence, and their duration. I then add a pivot table (see red circle in the image below), where I automatically calculate the total duration for each process. In the image below I have the pivot on the same Excel sheet for visualization, although usually I do my pivots on a separate sheet.

I then change the sequence by changing the numbers in column B below. In my example I numbered the processes 10, 20, 30, and so on. If I need a new process between two processes, I can just number it 25 and keep the sequence. I could also use decimal points and number them 1, 2, 3, 3.5, 4, and so on. Either way works. Don’t forget to update the pivot after you have changed the numbers. I keep on playing with the sequence until I am happy with the result.

However, if possible, I try to do it on paper as a group, because the group usually knows much more about the processes and their sequence limitations than I do. Besides, involving the group in decisions regarding their workplace is a sign of respect and will result in better morale.

I hope the tips and tricks on line balancing above have helped you. If you have any more, I am always eager to hear new tricks. This concludes my rather lengthy series of six posts on line balancing, even though I haven’t even touched on the topics of job shops, multi-machine handling, the pearl chain (sequence your products so that a high workload product is followed by a low workload product at the same station – i.e., a car with a sun roof followed by one without, so that the “sun roof station” can catch up ), etc. Maybe some other time. In the meantime, go out and organize your industry!

Line Balancing Series Overview

- Data Overview: List of products, list of tasks, and customer takt.

- Duration of Tasks: How to get the duration of tasks, especially if they differ among products.

- OEE Caveats: Potential problems when using the OEE to transform takt times to cycle times.

- OEE Usage and Flexibility: Once you have the OEE, how do you use it? Also a bit on flexibility.

- Balancing using Paper: Finally, actual line balancing using paper.

- Tips and Tricks for Balancing: Some Pro-Tips, and also a bit about line balancing using computers.

Thanks, Christoph. Enjoyed reading the whole set and great practical advice.

Hi Christoph

Thank you for the excellent article

Just one small doubt

What is the main advantage to have workers walking around in a u shape balaced line vs workers standing in one workstation and passing the part to the next one in the same u shape balanced line?

Hi Luis, these are two topics: Multi Machine Handling, and the line layout. Multi Machine handling allows you to scale up capacity by adding and removing workers, as well as having a machine work while the operator loads or unloads another machine. The U Layout reduces walking distance between processes, and also allows workers to handle both processes at the beginning and at the end of the line, which has advantages if there are some problems. The workers are usually inside of the U, whereas the material is ideally supplied from the outside.

Hi Christoph

Thank you for the excellent article,I have question about the pearl chain (sequence your products so that a high workload product is followed by a low workload product at the same station,what is advantage for that arrange and vice versa

thanks and Best regards

Hi Frank, at one point I want to write more about the pearl sequence, but I did not yet get around to do it. It is a quite challenging topic if you want to go into depth.

Hi Christoph,

i have generated a different solution in excel for the yamazumi chart. The solution doesn’t use pivot, therefore you can see immediately the impact of changes.

If you want, i could give you the link of the website.

Greetings from the black forest

Roland

How can balance when we have dependency, equipment and manpower constraints between tasks?