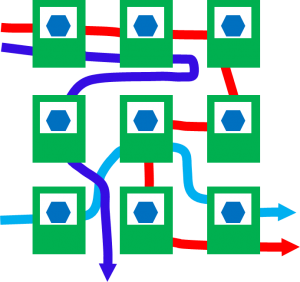

Job shops are a manufacturing system where the machines are not arranged in the sequence of the work steps (as in a flow line). Rather, the flow of the part conforms to the arrangement of the machines.

Job shops are a manufacturing system where the machines are not arranged in the sequence of the work steps (as in a flow line). Rather, the flow of the part conforms to the arrangement of the machines.

This post looks in more detail at the job shop, its advantages and disadvantages, and where it may be useful.

The Job Shop

A job shop is a production system where the material flow is subject to the location of the machines. In other words, the parts go to wherever the machine for the next work step is. Often, the machines are arranged in functional groups (i.e., a lathe department, a milling department, a heat-treating oven, assembly stations, and so on).

This differs from a flow shop, where the machines are subject to the material flow, and are set up so the next adjacent machine is in most cases also the next process step (more on this in my next post). It also differs from the project shop, where the part does not move at all.

Each part has a sequence of production steps. These may be different for every part, although often there are groups of parts that have a similar sequence. Some steps have to be done before or after other steps, while other steps are more flexible and the sequence can be varied. For example, if you produce an axle as shown in the image, you probably use a lathe early on. However, if you first drill the hole or mill the grooves makes no difference. The grinding, however, should come at the end.

Each part has a sequence of production steps. These may be different for every part, although often there are groups of parts that have a similar sequence. Some steps have to be done before or after other steps, while other steps are more flexible and the sequence can be varied. For example, if you produce an axle as shown in the image, you probably use a lathe early on. However, if you first drill the hole or mill the grooves makes no difference. The grinding, however, should come at the end.

The part then has to be processed at different machines in line with the production sequence. Often, there is more than one machine available. For example, there may be more than one lathe where the part could be worked on.

A part may also visit a machine more than once. For example, for precision parts there may be multiple washing steps at different times, all done on the same washing machine. Or a metal part may be annealed in an oven multiple times throughout the production sequence.

Overall, the sequence of which part is processed at which machine is usually only loosely defined.

Planning a Job Shop

If you are looking for a quick and easy way to effectively plan a job shop, sorry … there is no such thing! Job shops are almost always a chaotic mess if compared to flow lines. If they are not a chaotic mess, then a lot of effort is continuously put in to manage the system. Since it is hard to keep that effort up for longer periods, it usually ends up in a … well … chaotic mess.

Naturally, there are different software tools that make a plan for you and schedule which part is to be processed at which machine when and by whom. Unfortunately, these plans – which are difficult enough by themselves – are not dynamic. The problem is that a job shop is very sensitive to small changes. Even comparatively minor changes in the production system can change the sequence of parts at a machine, and hence can invalidate the entire plan. If a process due to some problems takes longer than planned, all subsequent parts on this machine are then delayed. Other machines waiting for the parts for further processing may be either idle, or – more likely – work on another part that is available. This creates a completely new sequence, which will invalidate the prior planning.

Overall, material flow is difficult to predict. As a result, information flow is also difficult to handle. It is hard to say beforehand which machine needs what product information. Logistics is also more challenged to figure out what exactly has to be moved from where to where and when. Let’s look at a few common and relevant KPIs in manufacturing, and how they behave in job shops:

- Lead Time (i.e., when the product will be ready for the customer): Hard to predict beforehand. Duration may fluctuate significantly between almost identical parts. Experienced shop floor managers will usually add quite a bit of safety, so they are late less often.

- Machine Utilization and Capacity (i.e., do I have enough machine capacity to satisfy the customer?): Same story. Due to the differences in product sequence, a lot of parts may arrive at one machine at the same time, exceeding capacity. Or there may be not enough parts, because the small changes lead to a different effect. Very hard to predict, high margin of error. It is hard to predict how many parts you can make in a certain time.

- Worker Assignment (i.e., which machine should be manned when): Closely related to machine utilization, hard to predict. Usually, the workers self-organize and keep themselves busy at whichever machine they can work on. Since some machines are often preferred by the workers over others, the utilization and lead time fluctuations may increase even more. Even if the worker has no preference, a “random” pick of the next task may often be the “wrong” one, since they do not have an overview of what is urgent and what not.

WIP Inventory (i.e., the stuff on the shop floor): Here I can make you a prediction. It will be a lot! Much more than a comparable flow line. Exact numbers are hard to estimate, but I guess you are lucky if you have only twice the WIP than a flow line. If you have little WIP, then – due to the erratic nature of a job shop – it is likely that some of your machines run out of parts while others still have too much. Inventory is often an insurance against idle machines, and in job shops you will need it.

WIP Inventory (i.e., the stuff on the shop floor): Here I can make you a prediction. It will be a lot! Much more than a comparable flow line. Exact numbers are hard to estimate, but I guess you are lucky if you have only twice the WIP than a flow line. If you have little WIP, then – due to the erratic nature of a job shop – it is likely that some of your machines run out of parts while others still have too much. Inventory is often an insurance against idle machines, and in job shops you will need it.

The timing of which part is processed when at which machine is highly sensitive to minor changes in the system! Any predictions have a high margin of error!

Advantages

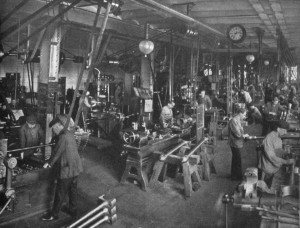

Job shops are still found in industry, as they do have some advantages depending on your situation.

First of all, job shops are easy to set up. While a flow shop needs considerable planning and preparation to be done correctly, for a job shop you just get the machines and put them on the shop floor. Although, in practice, you save planning during set-up but get much more and harder planning problems during operations. Similarly, expanding a job shop is also easier since it means merely adding more machines of the required type, rather than setting up and balancing a new flow line. Same for reducing production capacity. Related to this, a job shop may also require a lower investment than a comparable flow shop.

Job shops are also very flexible with their product spectrum. While a flow line is restricted to certain part groups, a job shop can produce a much wider variety of goods.

Job shops are more robust: The failure of a single machine can completely stop a flow shop. A job shop, however, may have multiple machines, and can work “around” the broken machine.

Disadvantages

There are also quite a lot of disadvantages. I already described above in detail the very difficult planning and scheduling issues.

There is also a lower productivity compared to flow lines. Both workers and parts have to move around much more, resulting in waste through transport and walking, on top of waiting for parts.

The workers also often have to be more skilled than at a flow line. As a result, labor costs may be higher. Details depend on the particularities of the production system.

Overall, job shops are also very hard to improve. Since a job shop is usually a mess, it is difficult to see how the standard works, if workers are deviating from the standard, and where you could start improving a job shop. Things like visual management, which normally would help you with this, are also more difficult. On the other hand, since most people shy away from improving job shops, there are often quite a few low-hanging fruits.

When to Use?

The pros and cons make it quite clear when a job shop may be suitable. It works especially if you have a very high demand on flexibility, offsetting all the other disadvantages. In this case a job shop may be a possibility.

Nevertheless, you should still try to go for a flow shop whenever possible. There are many examples of industries that were once thought to be typical job shop products but now have arranged their production in a flow shop. Examples are Boeing and Airbus jumbo jets, MAN diesel engines, and Trumpf machine tools to name just a few (see my post A Successful Example of Lean Implementation – Trumpf and its Synchro Manufacturing System for details on Trumpf).

I will talk about flow shops next. In the meantime, go out and organize your industry!

thanks Christoph Roser 😀

You’re welcome 🙂

I had a good laugh at this. 1st year out of university with a business degree, I started working at my family job shop in 2017… And I quickly realized, how challenging it is to schedule or plan a job shop. Thank you, now I don’t feel so bad. ?

This is a great article, and and as someone who has been working in various job shops for the better part of 25 years, I can certainly feel your pain.

There are a couple of things that help. The first is to master the application of Theory of Constraints in your business. It should be the framework of your planning, and tell you where you need to improve.

The other is to focus on the processes, not the product. Many job shops can build an almost infinite number of products, but they only have a few dozen processes. All the work that runs through your shop is some combination of those few processes, so focus on them, not the variation.

Anyway, good great work!

Yes, job shops need more effort to manage the processes. In flow shops, you usually have to manage only the first process, which makes it a lot easier.