One-piece flow is strongly connected to lean manufacturing. It moves each product to the next stage as soon as it is completed at the previous stage in the value stream. This brings lots of benefits. While I have written about one-piece flow before, in this post I would like to go into detail on the beautiful benefits of it.

One-piece flow is strongly connected to lean manufacturing. It moves each product to the next stage as soon as it is completed at the previous stage in the value stream. This brings lots of benefits. While I have written about one-piece flow before, in this post I would like to go into detail on the beautiful benefits of it.

Introduction

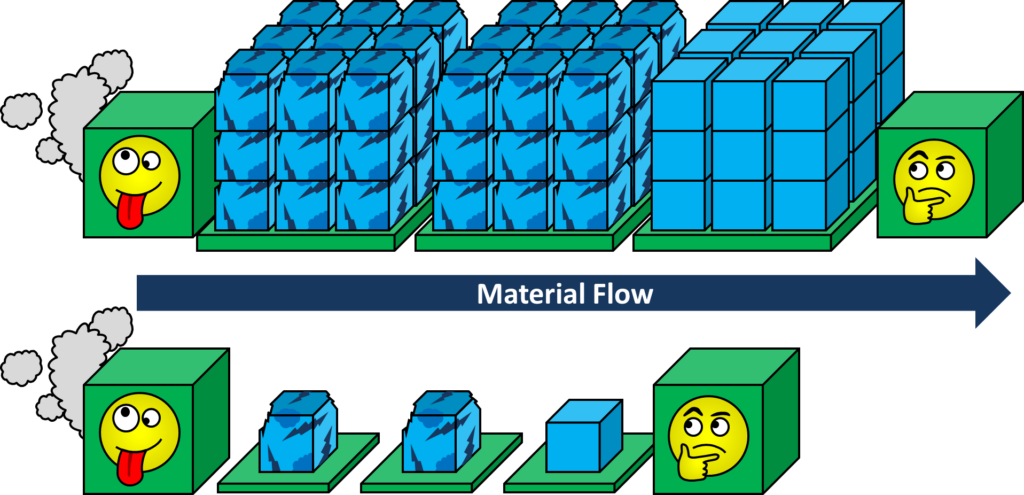

I have written about one-piece flow before. One-piece flow moves each product to the next stage as soon as it is completed at the previous stage in the value stream. There is no accumulation of larger batches for moving material. There is also no production of batches in parallel at the same station. The basic idea of one-piece flow is that you do not wait until you have a pallet/box/batch of parts before moving them to the next process, but that you move smaller quantities more frequently. Ideally, the transport quantity is one. The benefit of one-piece flow is a reduction of fluctuations and hence a reduction of work-in-progress inventory. You don’t get a big box and then nothing, but you get the parts one by one, ideally just in time when you need them.

If done right, one-piece flow has several advantages, most of them connected to having less inventory. Let me give you an overview.

Better Visual Management

Having fewer parts makes it a lot easier to see the state of your operations. For example, fewer parts make it a lot easier to see which process may be the bottleneck that other processes are waiting for. You can also find deviations from the standard easier through this improved visual management.

I find that the value of visual management is often underestimated. However, seeing immediately what the status is can be really helpful. Ideally you can see this directly by observing workers, processes, and inventories, but often additional information can be provided by andon boards or stack lights.

I find that the value of visual management is often underestimated. However, seeing immediately what the status is can be really helpful. Ideally you can see this directly by observing workers, processes, and inventories, but often additional information can be provided by andon boards or stack lights.

Faster Detection of Defects

One-piece flow, if done right, is likely to reduce the inventory, or at least the difference between the previous batch size and the new batch size. Due to this reduced inventory, you will detect defects faster. A highly simplified example with two processes is below. At one point, the first process starts to produce defective parts. This will be noticed by the second process. The fewer parts you have between the processes, the faster you will notice the problem. This reduces the number of parts that have to be thrown out or repaired.

Better Quality

Your quality will improve if you find defects faster. In some cases, however, quality can also improve due to one-piece flow reducing the likelihood of a defect in the first place. Especially for larger parts, batch processing may be a bit more chaotic. Assume you want to make a batch of 12 engine blocks as a batch as illustrated in the image. You add 12 crankshafts, always walking to each engine, then the pistons for each engine, and many more parts. How certain are you that you have not overlooked one engine when walking between these engines?

Your quality will improve if you find defects faster. In some cases, however, quality can also improve due to one-piece flow reducing the likelihood of a defect in the first place. Especially for larger parts, batch processing may be a bit more chaotic. Assume you want to make a batch of 12 engine blocks as a batch as illustrated in the image. You add 12 crankshafts, always walking to each engine, then the pistons for each engine, and many more parts. How certain are you that you have not overlooked one engine when walking between these engines?

Sure, if it is a crankshaft, you will notice if it is missing. But how about a simple O-ring, or one screw? In my view this has quite a bit of potential for mix-ups.

Less Inventory and Hence Shorter Lead Time

One-piece flow can reduce the inventory. Please do note, however, that inventory reduction is also possible without one-piece flow. We have inventory first and foremost to reduce fluctuations. Reducing fluctuations allows you to reduce inventory. (Alternatively, if you can afford to run out of stock, you can also reduce inventory without reducing fluctuations, but that is not always an option).

One-piece flow can reduce the inventory. Please do note, however, that inventory reduction is also possible without one-piece flow. We have inventory first and foremost to reduce fluctuations. Reducing fluctuations allows you to reduce inventory. (Alternatively, if you can afford to run out of stock, you can also reduce inventory without reducing fluctuations, but that is not always an option).

One piece flow is one way to reduce fluctuations. If you always fill a box/barrel/pallet or other kind of container with material before moving it to the next station, you have at least the fluctuation from filling and emptying your container repeatedly, even if there is no other fluctuation. Hence, one-piece flow will reduce this fluctuation, and hence allows you to reduce the inventory. Depending on the chaos in your system, however, this may be only a small part of the overall fluctuations.

But once the inventory is reduced, you also reduced the lead time. This reduced inventory will increase the flexibility of the production system. Reduced inventory will lead to faster lead times. Any changes will propagate though the system much faster, no matter if it is a custom order, a design change, or a new product.

Better Efficiency

In many cases, one-piece flow can also improve efficiency by reducing material handling. Normally, you pick up the completed part and put it down in the batch. Later, you pick the part up again and put it in the next process. Hence, you need at least two material-handling steps, and potentially more if you move the material into storage and back out again.

In many cases, one-piece flow can also improve efficiency by reducing material handling. Normally, you pick up the completed part and put it down in the batch. Later, you pick the part up again and put it in the next process. Hence, you need at least two material-handling steps, and potentially more if you move the material into storage and back out again.

If there is no buffer between the stations, then you need only one material handling: Pick up the part from the previous step and move it into the next step. This is one of the reasons why Chaku Chaku lines are so efficient. See also the animation at the beginning of this article.

Better Cash Flow

Finally, there is better cash flow due to reduced lead time. Again, this is probably not a huge effect from one-piece flow alone, as other fluctuations may prevent you from reducing your inventory even more. But it helps to get the products to the customer faster and hence gets you paid quicker.

Finally, there is better cash flow due to reduced lead time. Again, this is probably not a huge effect from one-piece flow alone, as other fluctuations may prevent you from reducing your inventory even more. But it helps to get the products to the customer faster and hence gets you paid quicker.

Overall, there are quite a few advantages to one-piece flow – some larger, some smaller. But especially if you have already reduced your fluctuations, going to one-piece flow can help you to become even better. Now, go out, flow where you can and pull where you can’t, and organize your industry!

P.S.: This blog post was inspired by a rolling ball lean game by David Barroso Perez and Jannis Schulz. Many thanks for showing me 🙂

And….

When work content is coordinated with takt time, each task taking (takt time – %), workers get into flow and problem identification becomes even better. Takt time is a vital consideration in designing one-piece flow.

All this for a better competitive position!