In my last two posts I talked about the qualification matrix, where you match the skills of your people to the skills needed for your business. This can be expanded with another axis, as for example the skills needed for certain products. This connects your people to your products through skills. It is also more useful for products where a single person assembles an entire product.

In my last two posts I talked about the qualification matrix, where you match the skills of your people to the skills needed for your business. This can be expanded with another axis, as for example the skills needed for certain products. This connects your people to your products through skills. It is also more useful for products where a single person assembles an entire product.

Quick Recap

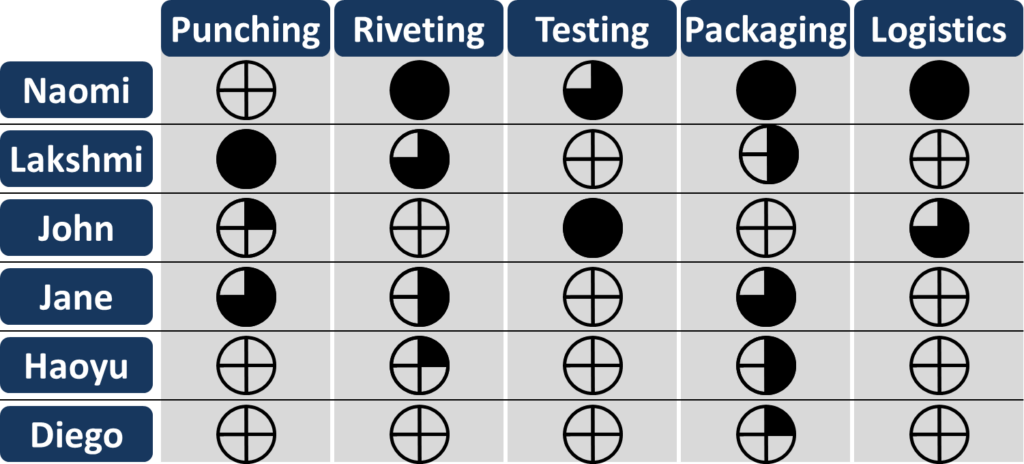

As explained in my last post, the qualification matrix is a simple matrix with a list of people on one axis and a list of their qualifications on the other axis. This can be used for work assignment, identifying training needs, and for employee evaluation, although I am hesitant on the last one.

It is quite possible to make similar matrices with other axes. One example I have seen is a combination of skills and products.

Skills and Products

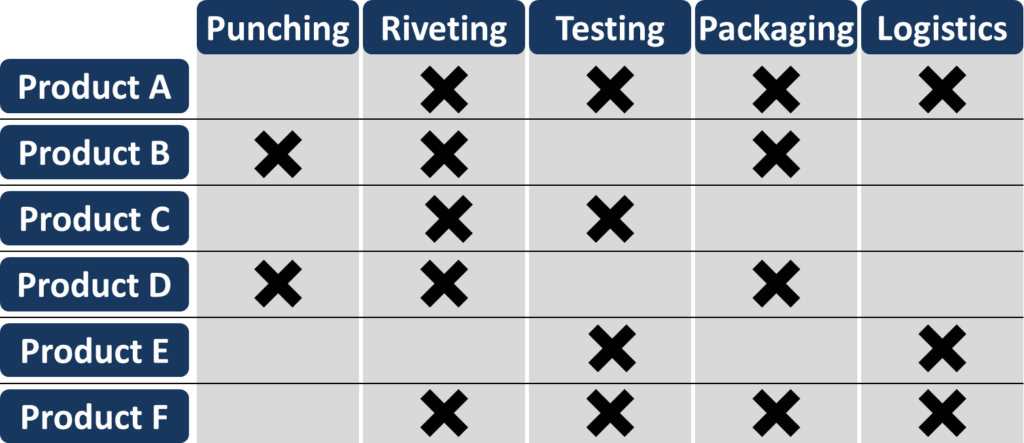

Sometimes, you find very similar matrices, but they compare the skills with the products. In other words, they list which skills you need for what product. An example is given below. This shows the different qualifications needed to make a certain product. You need people with the right skills to make certain products.

Three Axes

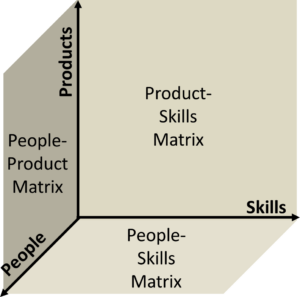

You have three axes: skills or qualifications, people, and products. Because, if you have a regular qualification matrix (or skills matrix) and a skills-product matrix, then you can easily combine them. You connect the products with your people through the skills that your people have and your products need.

You have three axes: skills or qualifications, people, and products. Because, if you have a regular qualification matrix (or skills matrix) and a skills-product matrix, then you can easily combine them. You connect the products with your people through the skills that your people have and your products need.

You can combine these two matrices as shown below. The top half shows which products need which skills, and the bottom half shows which employee has which skills. The type of skills naturally has to be identical.

Three Different Matrices

Overall, you can get three individual matrices out of this information of people, skills, and products.

- A People-Skill matrix (the classical qualification matrix)

- A Skill-Product matrix to see which products require which skill

- A People-Product matrix to see which people you need to make which products

We already looked at two of them. There is one side missing.

The People-Product Matrix

As the name says, now you can look at the relationship between the people and your products. Which person can do which product. This could be used in assembly lines, but in assembly lines you usually have one person per task, and it is not necessary for every person to be able to do every task. However, it does become more helpful for work cells with few employees, or generally any system where an employee may have to cover all tasks needed for the product. This could be a work cell with only one person, or a line organized through a rabbit chase.

The example derived from the two other matrices above is shown below. Only Naomi can assemble product A, C, and F. Lakshmi and Jane can both do products B and D, and both Naomi and John can do products E. Employees Haoyu and Diego are still in training and not qualified to do any product on their own.

This way you can quickly see if you can produce a certain product depending on the availability of skilled workers. You could even use the Harvey balls as a weight and calculate a percentage skill level of each employee for each product. However, please note that the Harvey balls may have higher qualifications than needed for mere assembly. You only need a person to do the assembly on their own.

If the Harvey ball has the levels 0) unskilled, 1) with supervision, 2) independent work, 3) trainer, and 4) can improve, then you need only “half a ball” of skill to assemble a product. Hence any worker who has a skill level of at least half a ball counts as 100% for this task. A quarter ball would be 50%. Summing up the different skills for the different required tasks would give you a percentage of qualification of each worker for one product, ranging from 100% (can do it completely) to 0% (can’t do anything yet). This helps you also to see where a little bit of training could qualify a worker to complete a product entirely.

It is overall an interesting approach that can help you especially if workers have to assemble an entire product. It can also be modified for covering parts of a product (i.e., who can do the first half and who can do the second half of one product). On the other hand, if you have a fully staffed assembly line where every worker takes care of only a single task, then the additional axis may not be necessary. Use such tools if you need them, not merely because you can do them. Now, go out, make sure you have the right skilled people to create your products, and organize your industry!

P.S.: Many thanks to fellow nerd Franck Vermet for the input 🙂