Single Minute Exchange of Die (SMED) to reduce and shorten changeover times is one of the best-known methods in lean manufacturing. However, the original steps as shown by Shingo have, in my view, potential for improvement. Hence, I restructured the changeover workshop based on my experience with SMED to make it easier and more straightforward. This rework is not groundbreaking or revolutionary, but merely a few small changes to make it easier to use. As it is popular nowadays, I also added a 2.0 after SMED for my SMED 2.0.

Single Minute Exchange of Die (SMED) to reduce and shorten changeover times is one of the best-known methods in lean manufacturing. However, the original steps as shown by Shingo have, in my view, potential for improvement. Hence, I restructured the changeover workshop based on my experience with SMED to make it easier and more straightforward. This rework is not groundbreaking or revolutionary, but merely a few small changes to make it easier to use. As it is popular nowadays, I also added a 2.0 after SMED for my SMED 2.0.

Introduction

The classical SMED by Shingo is based on the quick changeover workshops at Toyota, which in themselves were inspired by many other companies and individuals. The classic steps by Shingo are as follows.

- Measure changeover times.

- Identify internal and external elements.

- Move as many elements as possible to external.

- Shorten internal elements.

- Shorten external elements.

- Standardize and maintain new procedure.

While this contains all the relevant elements for a SMED, the arrangement could be better. I am also missing the verification whether the new sequence actually works and the PDCA at the end. Hence, let me redo the sequence:

SMED 2.0

As with any improvement, you should first identify and prioritize what you want to improve. Once you know your topic, you should set up a small team of people qualified in the topic and give them time to work. With these basics out of the way, let’s start SMED 2.0.

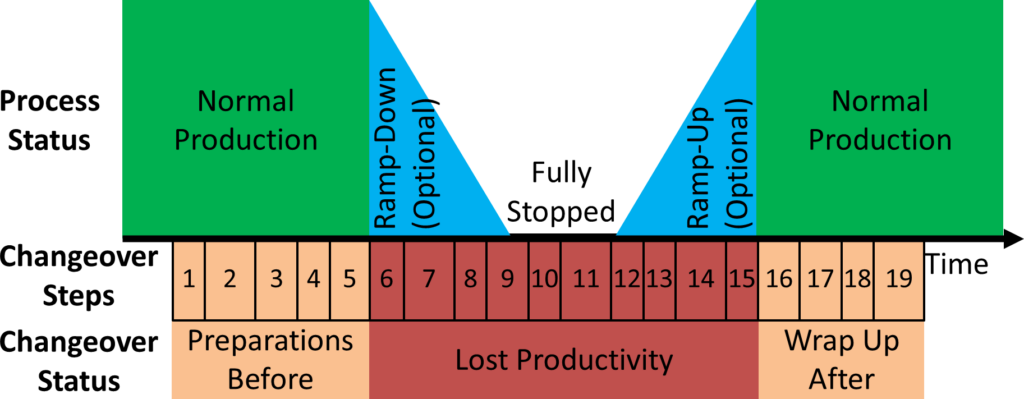

Current State Changeover

The first step is, of course, an analysis of the current state of the changeover. Observe a typical changeover (maybe video it if the employees agree). Follow all people involved in the changeover and see what they do and how long it takes. Also take note when the main process is stopped, when it was started again, and when the first good part at full speed was produced. The last two points may be identical, but sometimes there is some set-up, adjustments, warm-ups, or similar activities between starting the process and regular production. Sometimes you may also find a ramp-down procedure at the beginning in addition to the ramp-up at the end. The goal is to reduce the lost productivity, including the ramp-down, the fully stopped period, and the ramp-up. Using the nomenclature of Shingo, I also call these the internal steps, whereas the preparation before and the wrap up after are external steps.

Ideally, at the end you have an Excel table with a list of steps, their sequence, and their duration. Common pitfalls are overlooking some early preparations that happened before the stop of the machine. You may also observe more than one changeover, although often only one changeover is observed, relying on the knowledge of the people on the improvement team to know the differences in the changeovers.

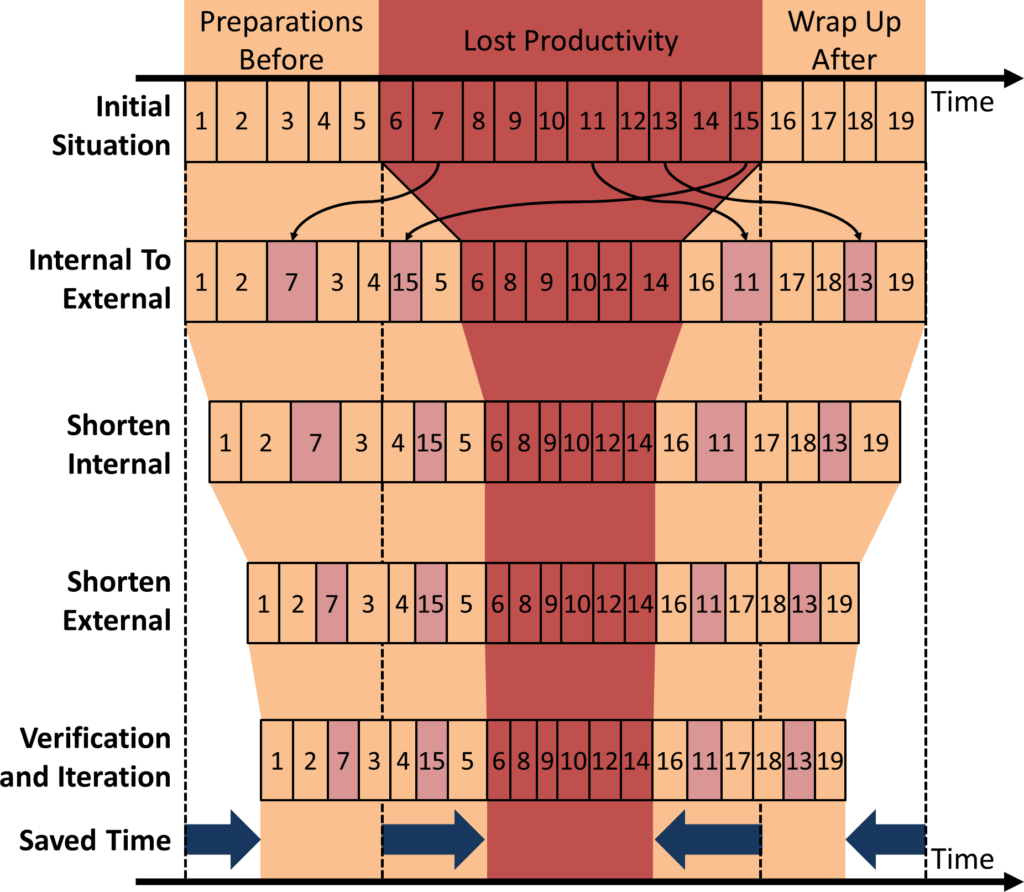

Move Internal to External

The next step is to look closer at the tasks between the ramp-down and the ramp-up of the process. Which ones can you move before or after to the preparations or wrap-up? Are there steps that can be eliminated completely? What is necessary to do so? A mere organizational change? A technical change? A better tool? An extra employee to help out? How long will it take to implement?

Shorten Internal Steps

You should also look at the remaining steps between start of ramp-down and end of ramp-up. Can you shorten them, or even eliminate them completely? Can you make them easier? How much effort is it to make the change, and how long will it take? If during this round of the workshop you have another idea to move the step outside of lost productivity, then do it!

Shorten External Steps

Similarly, you should also look at the preparation before and the wrap-up after the changeover, the external steps (including the ones you just moved to external). Can they be shortened, eliminated, or made easier? How much effort is it to make the change, and how long will it take?

Please note that the shortening of external steps is much less important than the moving and shortening of internal steps. Reducing external steps reduces the time for the employees to do the changeover, which—depending on the duration and the frequency of the changeover—may be worthwhile. However, reducing or eliminating internal steps will give you much more benefit. Besides the reduction of the time for the workers doing the changeover, you also get (probably much needed) production capacity…or, even better, smaller lot sizes. If you can move an internal step to external, it is worth it even if it takes longer externally.

Verification and Iteration

Missing in the original Shingo structure is the verification and iteration. At the end, you should check whether the new changeover sequence is doable. If you can, try it out with a real changeover. It may very well be that the new sequence has a bug, and two steps clash with each other. Such problems have to be resolved.

If you are also not yet satisfied with the new duration, you may iterate and go through the steps again. Is there any more time to be gained during the changeover internally (best) or externally (also good)?

If you need larger technical changes, you may depend on delivery and/or installation of your new gadgets. Will you wait with the new standard until these arrive, or is it worth the effort to have an interim standard?

Standardization

Once you and your people have agreed on a new changeover sequence, this needs to be put down in a new standard, and the workers need to be trained in the new standard.

PDCA

As always, don’t forget the PDCA. Do process confirmation to see whether the standard works and is still followed even some time after the workshop. If not, is the standard flawed, or do the operators need more training or supervision?

As always, don’t forget the PDCA. Do process confirmation to see whether the standard works and is still followed even some time after the workshop. If not, is the standard flawed, or do the operators need more training or supervision?

While I hope you are familiar with SMED, I also hope this post restructured it a bit. Again, it is not a major change, but a bit of twiddling and improving. Now, go out, reduce your changeover time so you can have smaller lot sizes, and organize your industry!

PS: Also check out my many other posts on SMED if you want 🙂

- Quick Changeover Basics – SMED

- The History of Quick Changeover (SMED)

- SMED – Creative Quick Changeover Exercises and Training

- What to Do with SMED: Reduce Lot Size or Increase Work Time?

- Series on changeover sequencing